A split-type multi-stage ventilation drum fermentation reactor and fermentation method

A fermentation method and split-type technology, applied in the field of fermentation reactors, can solve the problems of low utilization rate of effective volume, unreasonable air supply, large floor area, etc., achieve flexible installation and debugging, avoid anaerobic reaction, and benefit The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

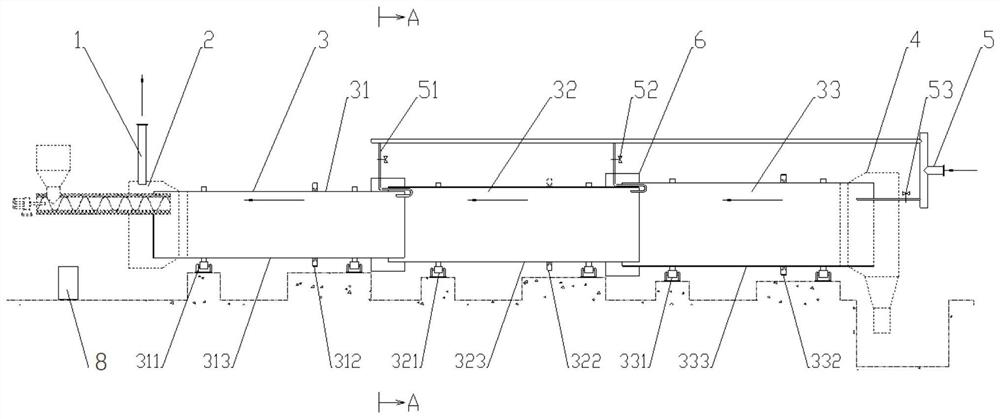

[0056] This embodiment discloses a split-type multi-stage ventilated drum fermentation reactor, which belongs to the field of organic solid waste treatment.

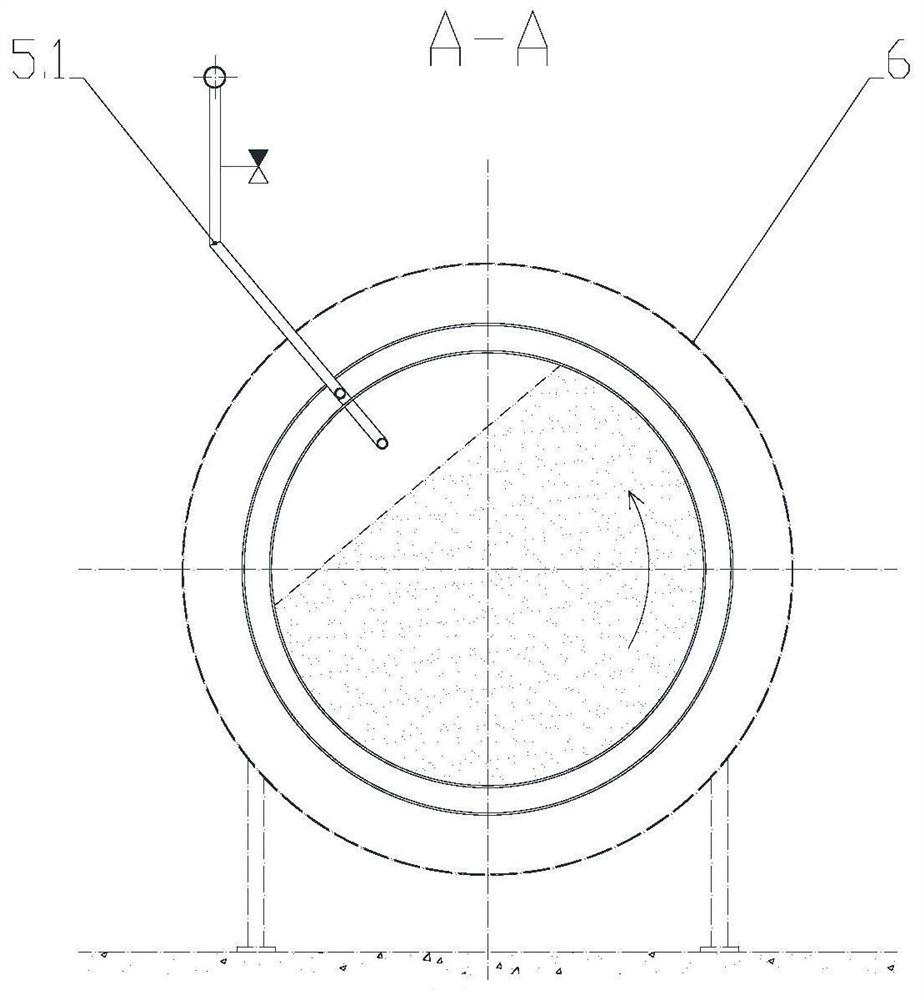

[0057]The structure of the split type multi-stage ventilated drum fermentation reactor is as follows figure 1 with figure 2 As shown, it includes a feeding device 1, a drum 3 and an air intake system 5. The feeding device 1 includes but is not limited to screw conveying equipment; the feeding device 1 is connected to the feeding end of the drum 3, and the connection is provided with a The feed end seal 2, the feed end seal 2 is provided with an air outlet; the air intake system 5 includes a main pipeline and 3 branch pipelines communicated with the main pipeline, and the 3 branch pipelines are respectively connected to the three sections of the barrel The end close to the discharge end is connected to supplement air for the multi-section cylinder respectively, and the discharge end of the drum 3 is connected to the ai...

Embodiment 2

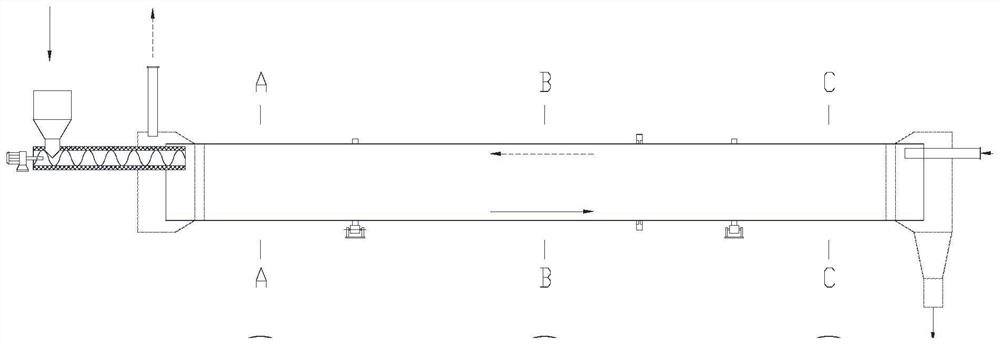

[0068] This embodiment discloses a split-type multi-stage ventilated drum fermentation reactor, the structure of which is basically the same as that of Embodiment 1. The difference is that the drum 3 in this embodiment includes 5 sequentially connected cylinders, which are respectively: The cylinder body of the feeding section, the cylinder body of the middle temperature section, the cylinder body of the high temperature section, the cylinder body of the cooling section and the cylinder body of the discharge section.

[0069] The fermentation method carried out by using the above-mentioned split-type multi-stage ventilated drum fermentation reactor includes the following steps: the material enters the drum from the feed end through the feeding device, the material advances along the axis direction with the rotation of the drum, and the air flows from the discharge sealing device The air inlet on the top enters the inside of the drum, and the air contacts the material countercur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com