Textile fabric automatic discharging and spreading device

A textile cloth and automatic blanking technology, which is applied in the cutting of textile materials, textile and papermaking, thin material processing, etc., can solve the problems of inability to realize continuous automatic cloth spreading and low degree of automation, and achieve good cutting effect, The effect of quick cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

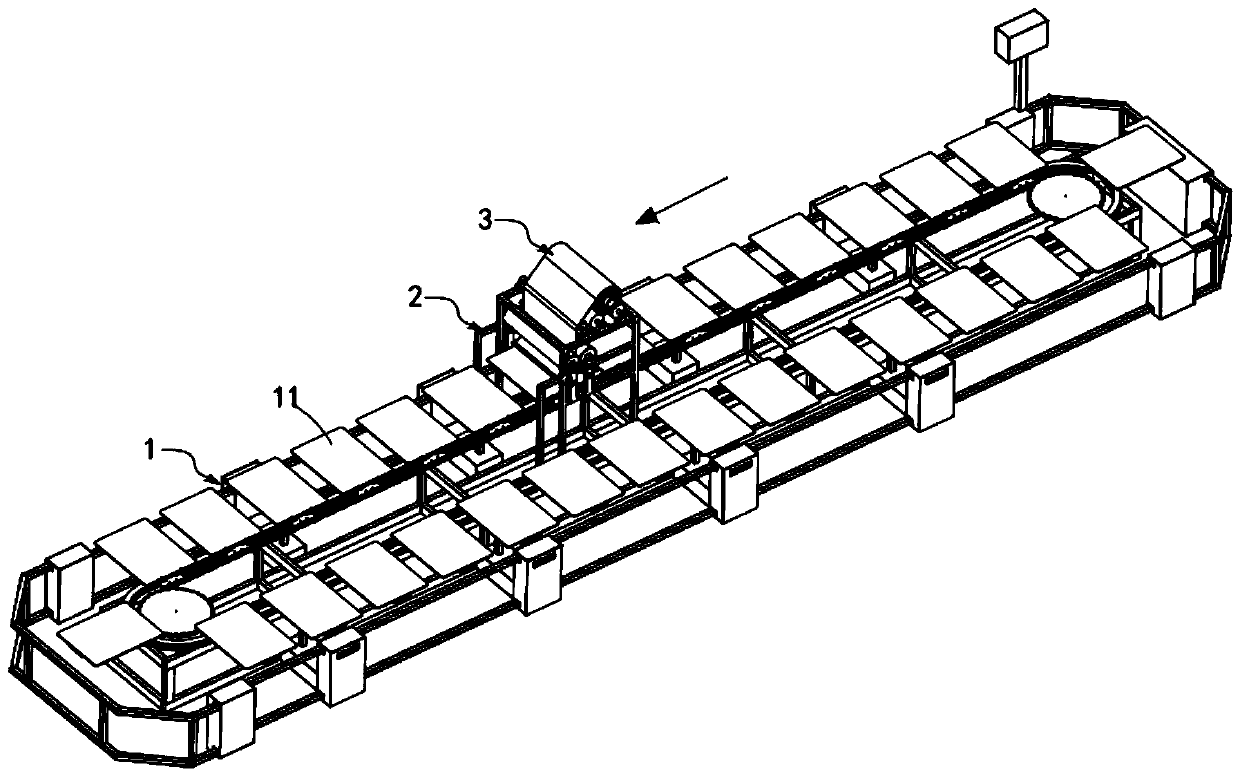

[0086] Such as Figure 1 to Figure 3 As shown, a kind of automatic unloading and laying device for textile fabrics includes a rotary conveying line 1, on which a number of spreading platforms 11 are equidistantly arranged, and the spreading platforms 11 are formed by the conveying line 1 drive rotary conveyor set, also includes:

[0087] A material rack 2, the material rack 2 is arranged on the conveying path of the conveying line 1, the top of which is provided with a freely rotating textile fabric roll 3, and the axial direction of the textile fabric roll 3 crosses the length of the conveying line 1 Width direction setting;

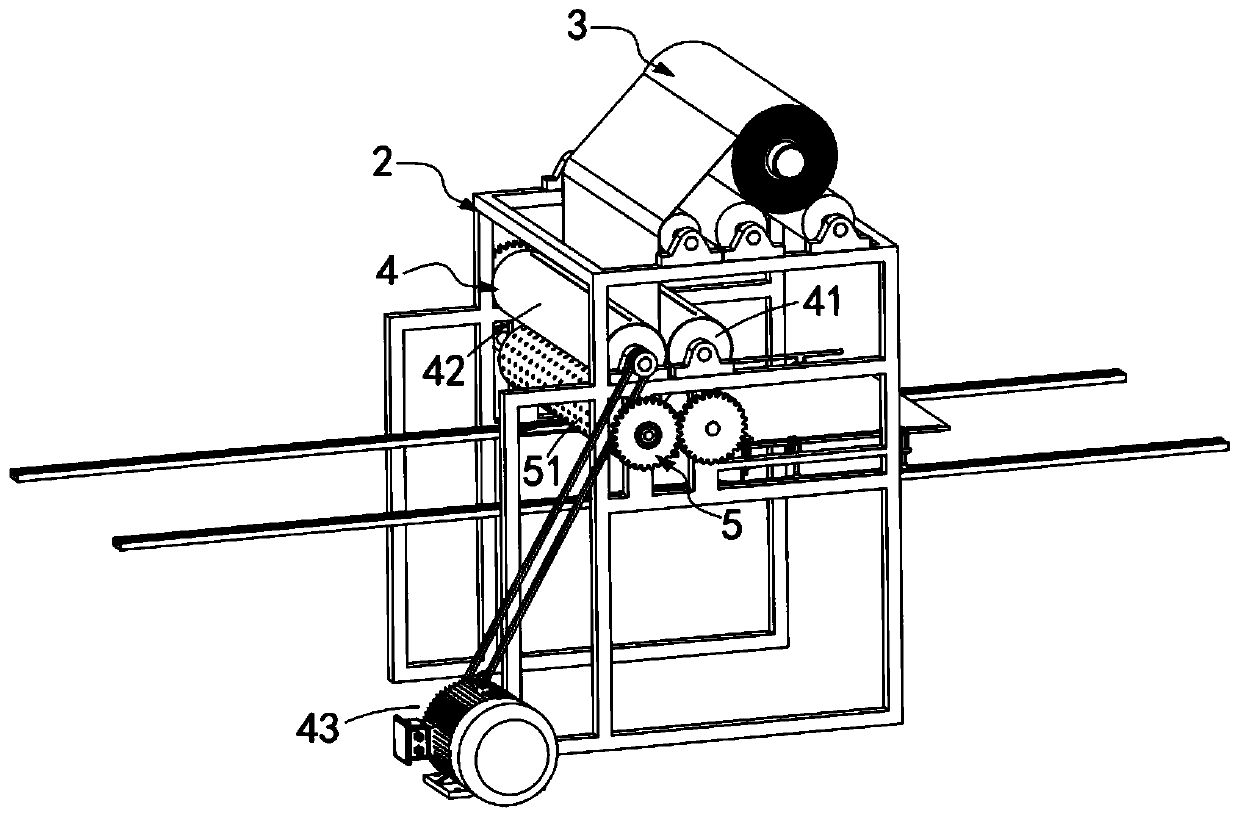

[0088] Cutting mechanism 4, described cutting mechanism 4 is arranged on the below of described textile fabric roll 3, and it comprises cutting roller assembly 41, resisting roller assembly 42 and driving assembly 43, and described cutting roller assembly 41 and described resisting roller assembly 42 are all Set parallel to the textile fabric roll 3, ...

Embodiment approach

[0108] Such as Figure 11 to Figure 17 As shown, as a preferred embodiment, the resisting roller assembly 42 includes:

[0109] Collision with the outer roller 421, the interior of the collision outer roller 421 is hollow, and the outer circumference of the roller body is provided with a knife slot 4211;

[0110] The collision end cap 422 is used to block the openings at both axial ends of the collision outer roller 421;

[0111] The conflicting blade 423, the two ends of the conflicting blade 423 are slidably arranged in the sliding groove 4221 on the corresponding conflicting end cover 422, and a conflicting knife groove 4231 for interspersing with the cutting blade 413 is provided on it ;

[0112] The conflicting eccentric shaft 424, the conflicting eccentric shaft 424 coaxially passes through the conflicting outer roller 421, it is set in conflict with the conflicting blade 423, and it drives the conflicting blade 423 to slide to the insertion Sipe 4211; and

[0113] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com