Used for aircraft composite materials, fonts, tendon wall boards, co -adhesive processing methods

A composite material and reinforced wall panel technology, which is applied in the field of composite material manufacturing, can solve the problems of difficulty in ensuring thickness uniformity, film and resin flow, and long truss axis offset, etc. The effect of uniform force and guarantee of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

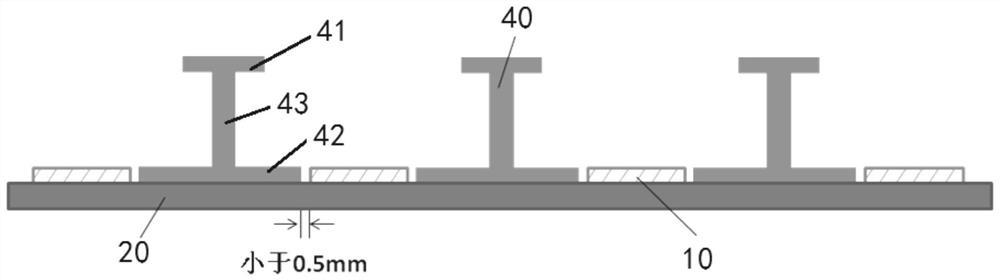

[0030] The implementation and use of the preferred embodiments of the present invention will be discussed in detail below in conjunction with the accompanying drawings. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention and do not limit the scope of the invention. The expression of the structural position of each component such as up, down, left, right, top, bottom, etc. in the description is not absolute but relative. These directional expressions are appropriate when the various components are arranged as shown in the drawings, and when the positions of the various components in the drawings are changed, these directional expressions are also changed accordingly.

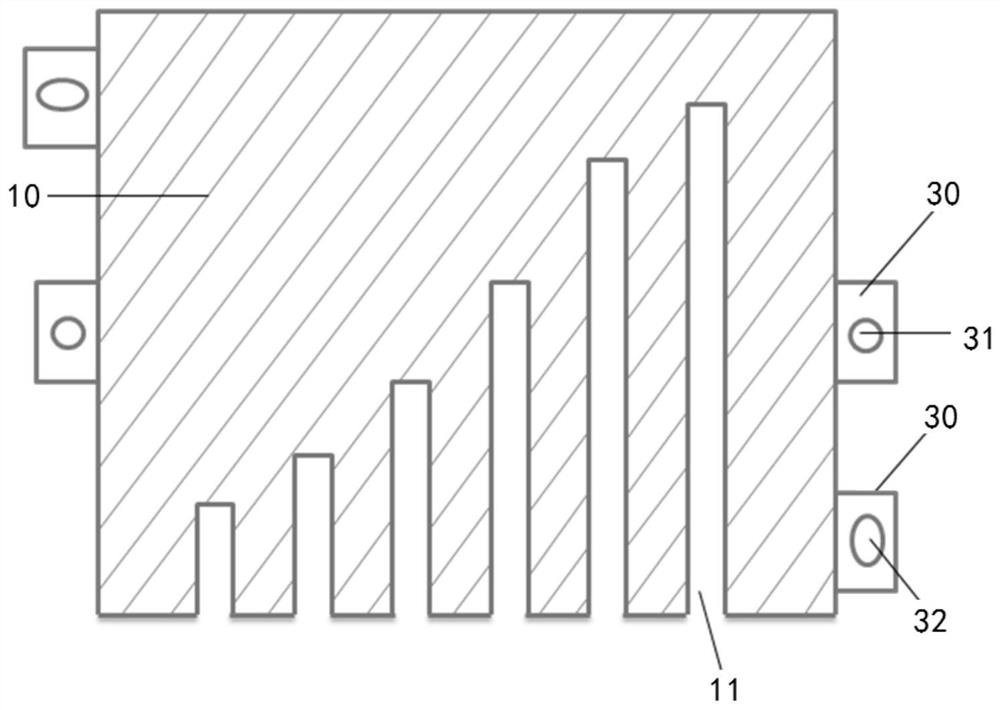

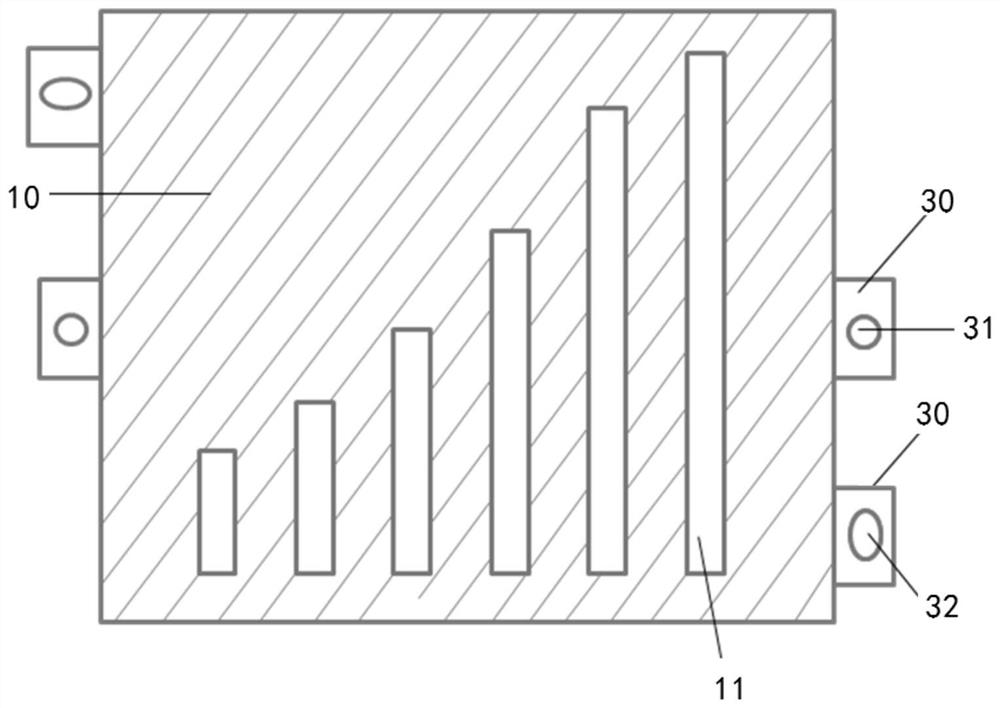

[0031] Such as Figure 1 to Figure 5 Shown in, according to the processing method of composite I-shaped reinforced wall panel of the present invention co-glued forming is realized through the following steps:

[0032] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com