Still kettle track butt-joint device

A docking device and autoclave technology, which is applied to ceramic forming machines and manufacturing tools, can solve problems such as unfavorable driving stability of steamed trolleys and damage to the first track, so as to improve driving stability, reduce collisions, reduce The effect of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

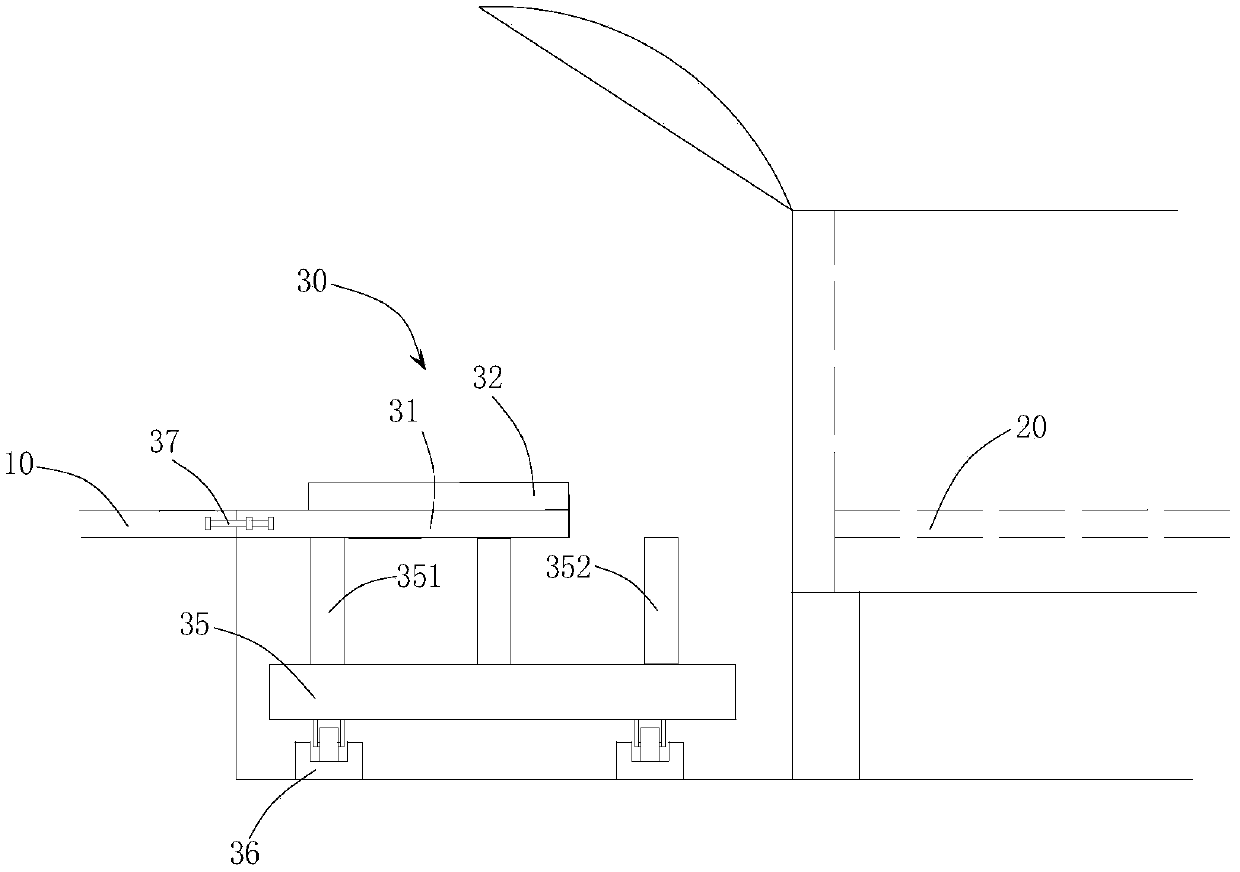

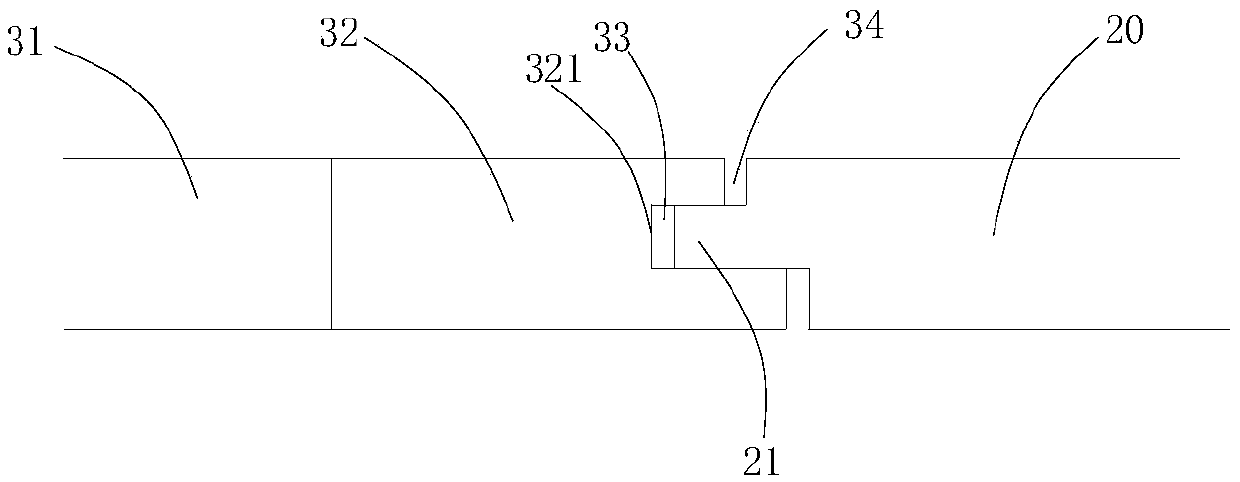

[0021] Such as figure 1 , 2 As shown, a kind of autoclave rail docking device of the present invention, the autoclave rail docking device includes the rail 10 in front of the kettle, the inner rail 20 in the kettle and the connecting rail movable between the rail 10 in front of the kettle and the inner rail 20 in the kettle 30. The connecting track 30 includes a fixed track 31 and a movable track 32. The movable track 32 is rotatably connected to the fixed track 31. The end of the movable track 32 away from the fixed track 31 is provided with a recess 321. Cooperating with the convex part, the movable track 32 rotates to be flush with the inner rail 20 of the kettle, and the convex part is inserted into the concave part 321, and there is a reserved distance between the end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com