Resin diamond grinding wheel

A diamond and resin technology, applied in the field of grinding tools, can solve problems such as rising product costs, large dynamic balance, and abrasive layer drop, and achieve better grinding results by overcoming insufficient assembly space, overcoming large dynamic balance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

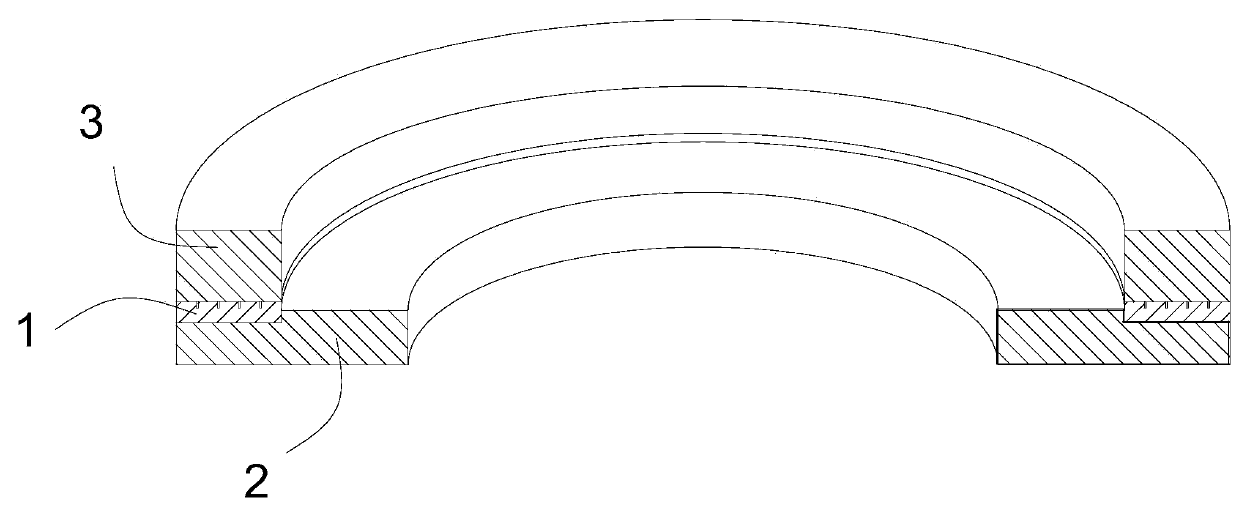

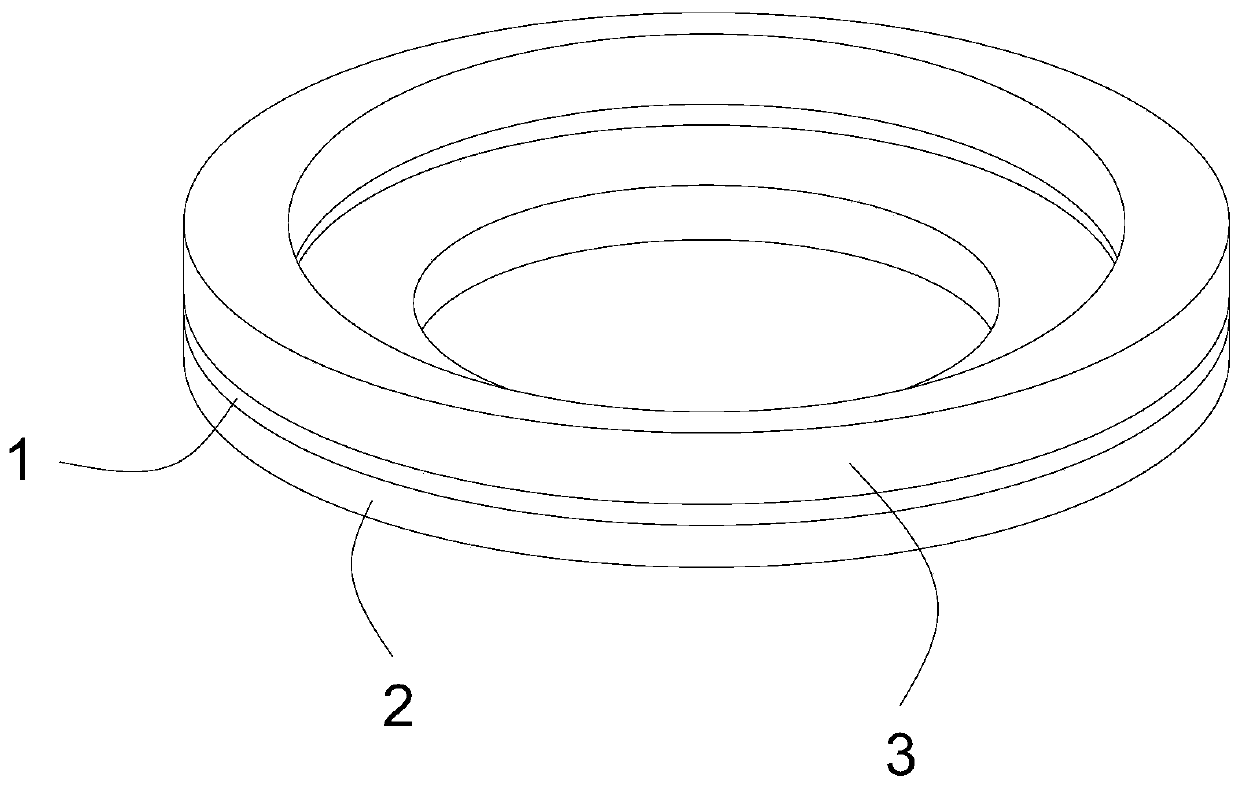

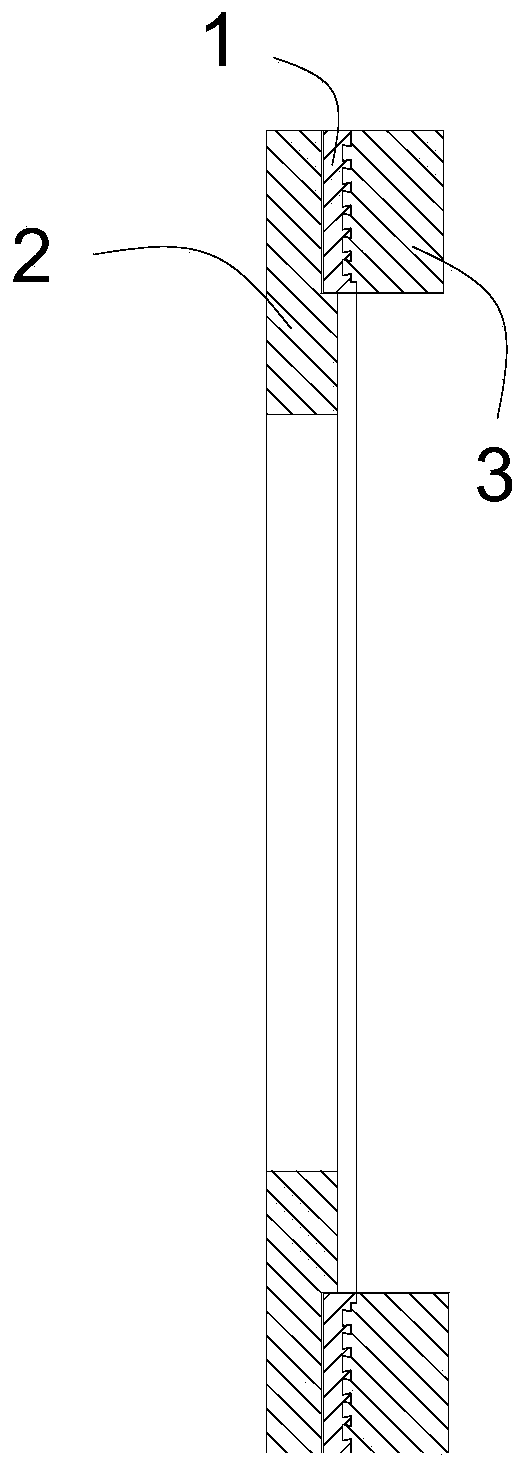

[0029] Such as Figure 1-8 Shown, the present invention shows a kind of resin diamond grinding wheel, comprises substrate and abrasive material layer 3, and described substrate is the aluminum substrate 1 of ring shape, and described abrasive material layer 3 is the ring-shaped resin bond diamond layer, and described abrasive material Layer 3 is embedded on the aluminum base 1 and arranged concentrically with it to reduce the dynamic balance defect of the grinding wheel. The grinding wheel also includes a ring-shaped steel base, and the steel base is arranged at the lower end of the aluminum base 1 and is connected to the aluminum base 1. The aluminum base 1 is arranged concentrically, and the steel base and the aluminum base 1 are connected by gluing or screws. That is, the present invention utilizes the rigid base 2 to connect with the aluminum base 1 by gluing or screwing, increases the thickness of the base, enhances the strength of the base, and overcomes the defects of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com