Bearing roller anti-bumping trigger box and anti-bumping method

A bearing roller and anti-collision technology, which is applied in the field of material boxes, can solve the problems of the rollers being difficult to collide with each other and cooperate with loading, so as to achieve the effect of reducing collision, reducing collision and high tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

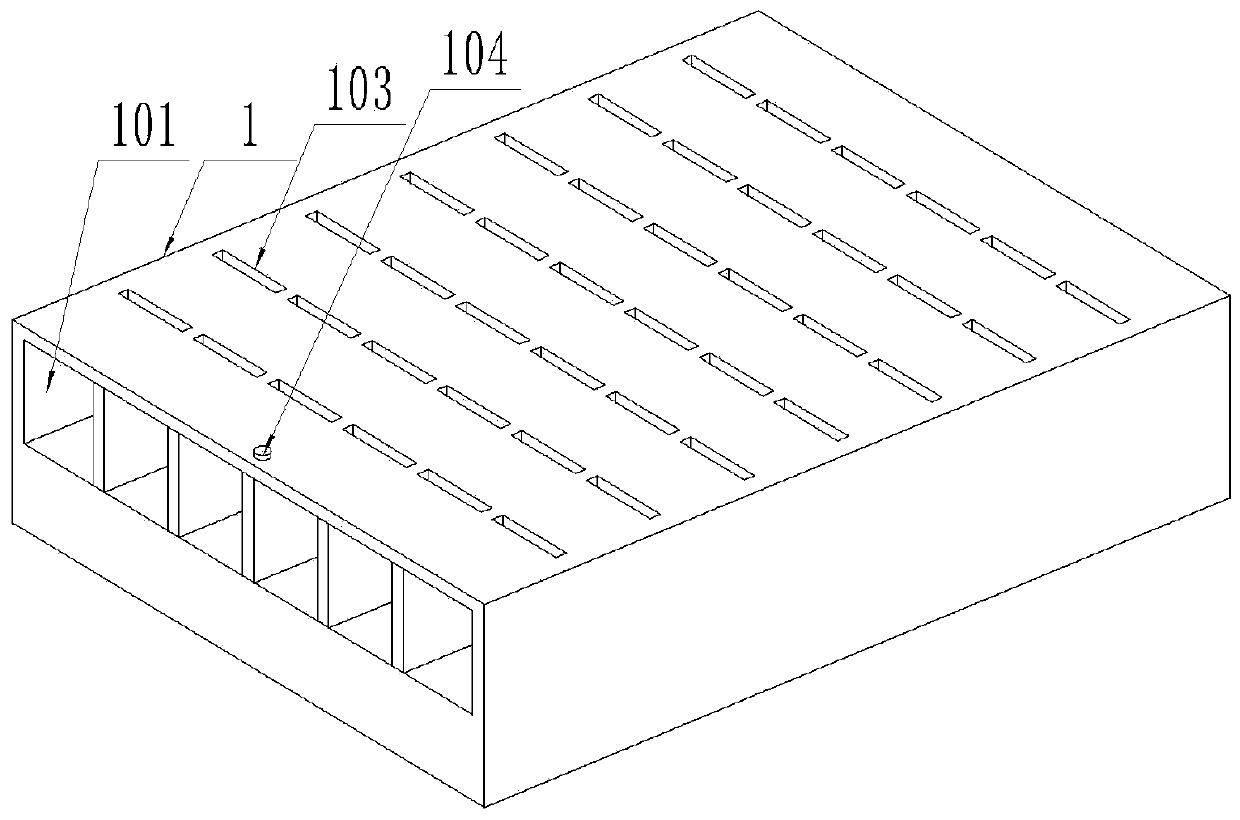

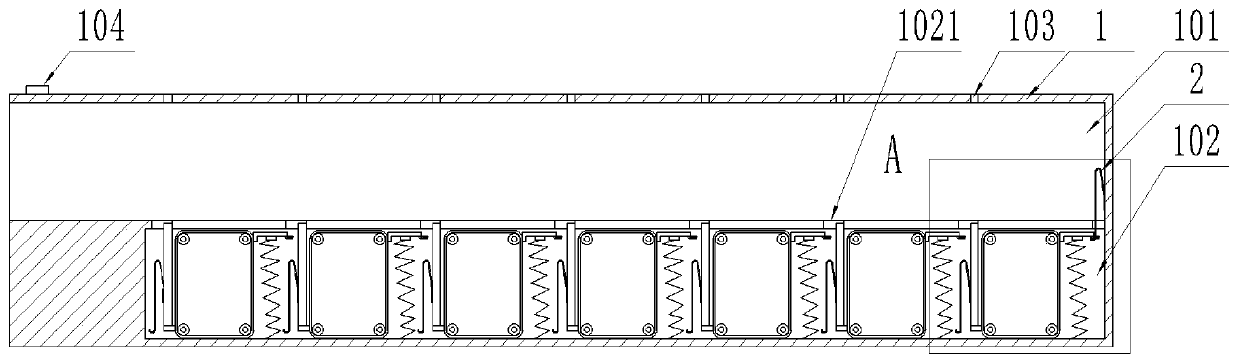

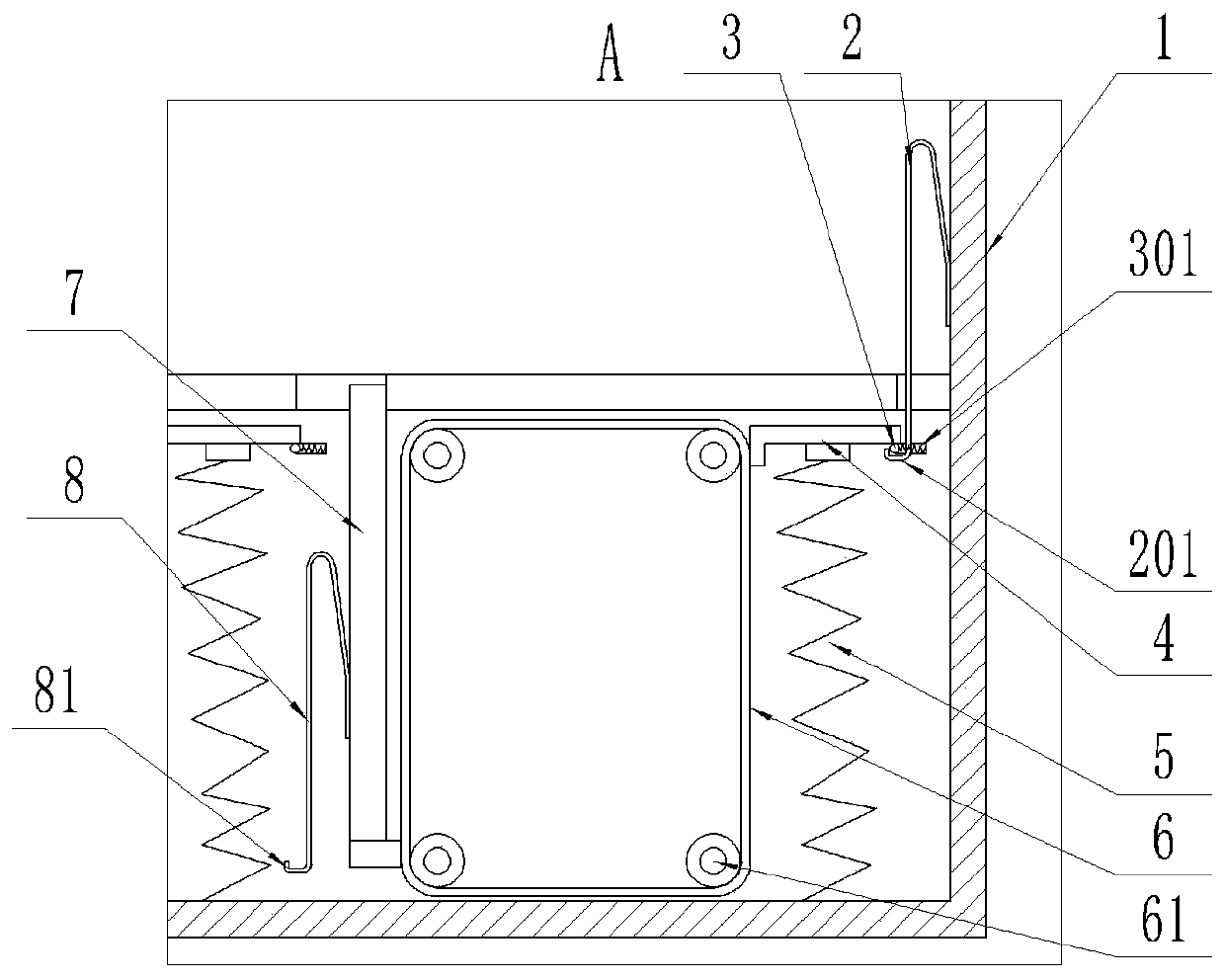

[0058] A bearing roller anti-collision trigger box, wherein, such as Figure 1-6 As shown, it includes: a box body 1 , a first elastic piece 2 , a limiting portion 3 , a return spring 301 , a pressure portion 4 , a tension spring 5 , a reversing belt 6 , a trigger plate 7 , and a second elastic piece 8 .

[0059] Such as figure 2 As shown, the box body 1 has a raceway 101 and a trigger space 102, the left end of the raceway 101 communicates with the outside world, and the right end of the raceway 101 has a wall to block it. The trigger space 102 has a connection port 1021 , and the connection port 1021 communicates with the trigger space 102 and the raceway 101 .

[0060] Such as image 3 As shown, the right end of the first elastic piece 2 is arranged on the right end wall surface of the raceway 101, the left side of the first elastic piece 2 extends into the trigger space 102, the first elastic piece 2 has a first hook 201, and the first hook 201 is formed by The lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com