Automatic feeding and slicing device for aluminum alloy profiles

An aluminum alloy profile, automatic feeding technology, applied in metal processing and other directions, can solve the problems of spark splash, injury, reduce the processing efficiency of aluminum alloy profiles, etc., and achieve the effect of avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

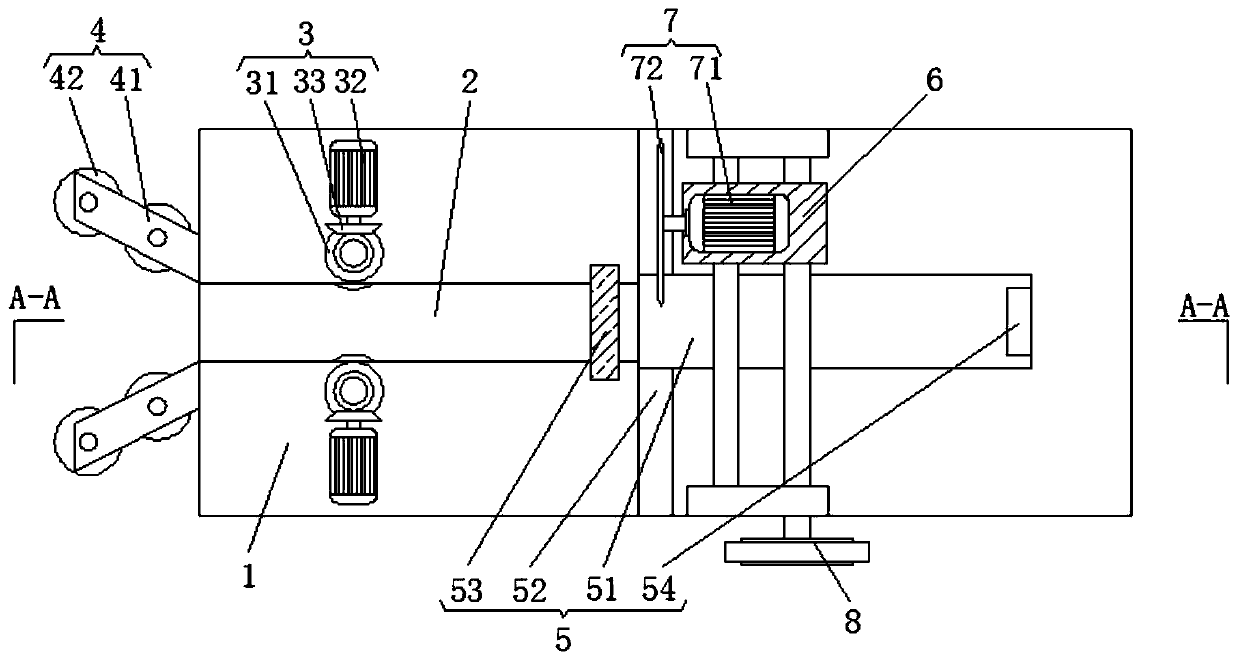

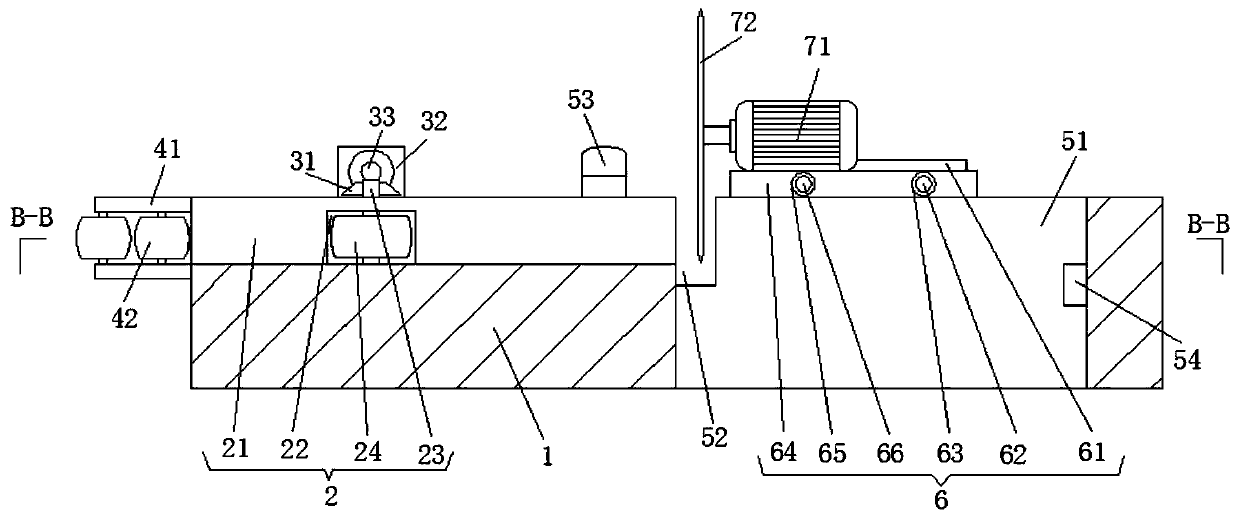

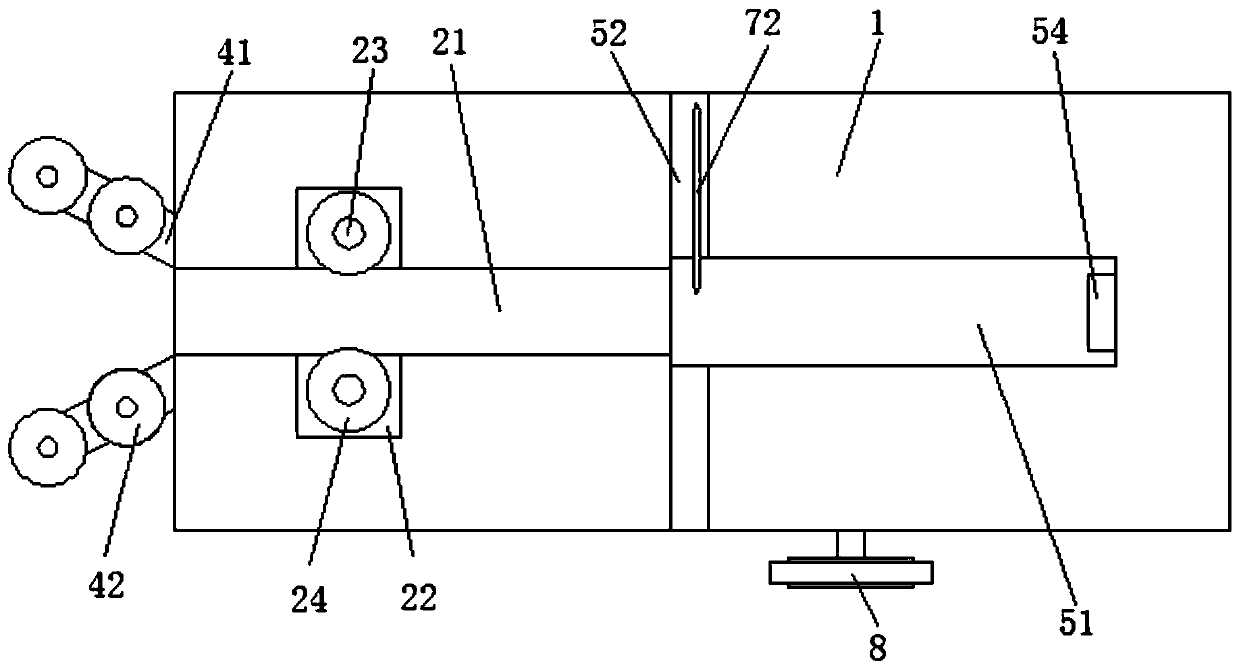

[0032] Such as Figure 1-5 As shown, this embodiment adopts the following technical solutions:

[0033] An automatic feeding and slicing device for aluminum alloy profiles, comprising a base 1, the upper surface of the base 1 is provided with a conveying mechanism 2, and the upper surface of the base 1 is fixedly connected with two first driving mechanisms 3 symmetrically with respect to the conveying mechanism 2 A guide mechanism 4 is fixedly installed on the side wall of the base 1 corresponding to the position of the conveying mechanism 2. The end of the conveying mechanism 2 away from the guide mechanism 4 is provided with a cutting positioning mechanism 5, and the base 1 corresponding to the position of the cutting positioning mechanism 5 A moving mechanism 6 is fixedly connected to the upper surface, and a cutting mechanism 7 is fixedly installed on the upper surface of the moving mechanism 6. A second driving mechanism 8 is fixedly connected to the base 1 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com