A rejection device applied to the slideway of a can stretching machine

A technology for rejecting devices and pop cans, which is applied in the field of pop can production and can solve problems such as deformation of pop cans and easy leakage of pop cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0032] When the punched and stretched blank enters the stretching machine, start the stretching machine. Within a period of time after the stretching machine is started, the temperature of the stretching die will gradually increase from low to the specified temperature. , the height of the thinned and stretched cans cannot reach the qualified height, so it is necessary to remove the unqualified cans, usually by manual removal. Therefore, when manually picking up, it will touch the subsequent qualified cans, causing the subsequent cans to deform and produce unqualified products. Based on the above problems, the technical solution of the present invention is further adopted.

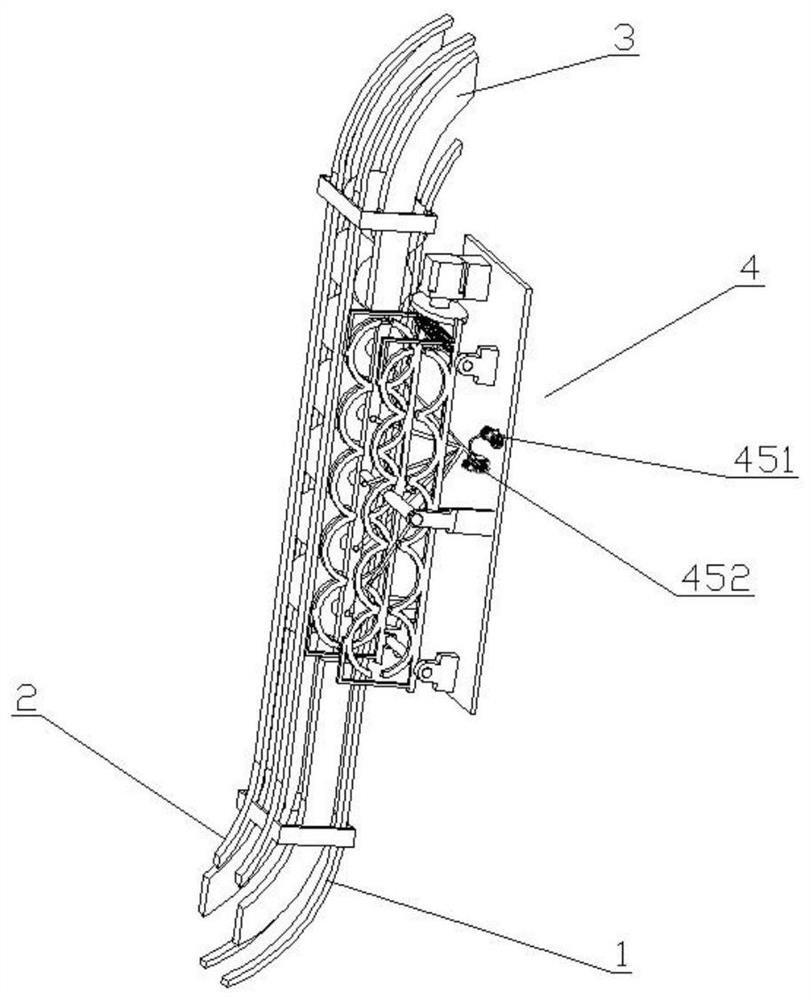

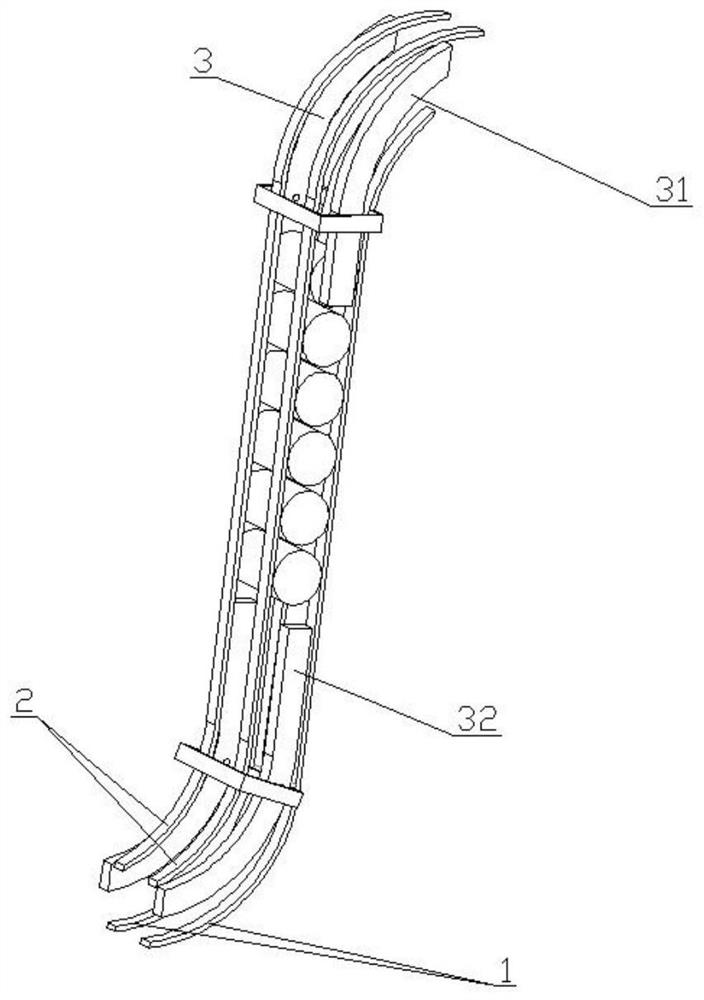

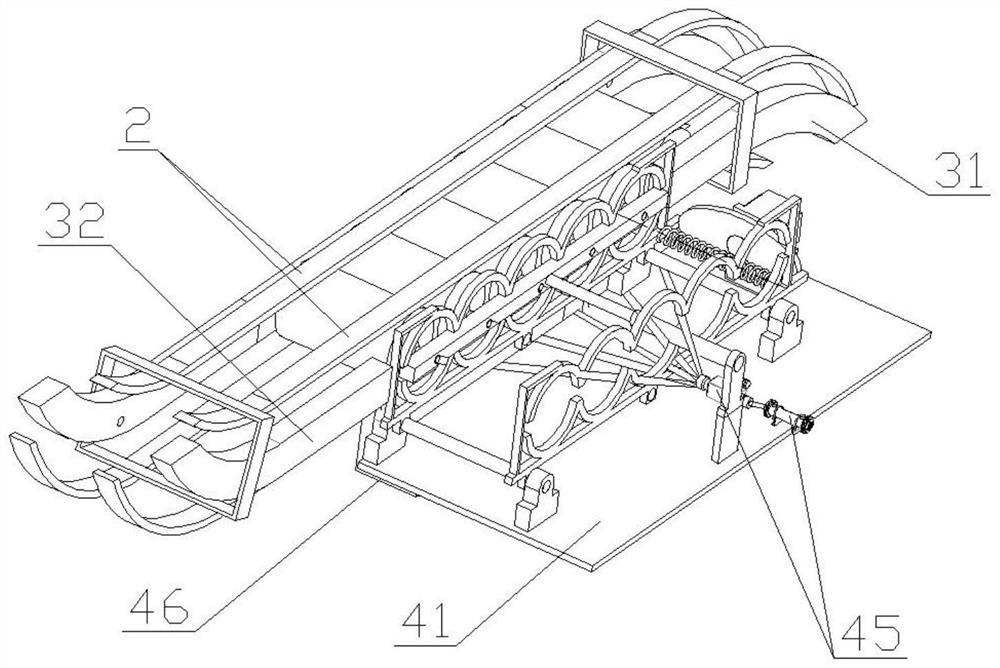

[0033] see figure 1 as well as figure 2 , the present invention is a rejecting device applied to the slideway of a can stretching machine, comprisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com