Caramel-flavor yoghourt with low content of advanced glycation end products and preparation method thereof

A technology of advanced glycosylation and end products, which is applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve problems affecting the taste of final products, and achieve delicate taste, high stability and excellent preparation process Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for preparing charcoal-fired yoghurt with low content of advanced glycation end products, the operation steps are as follows:

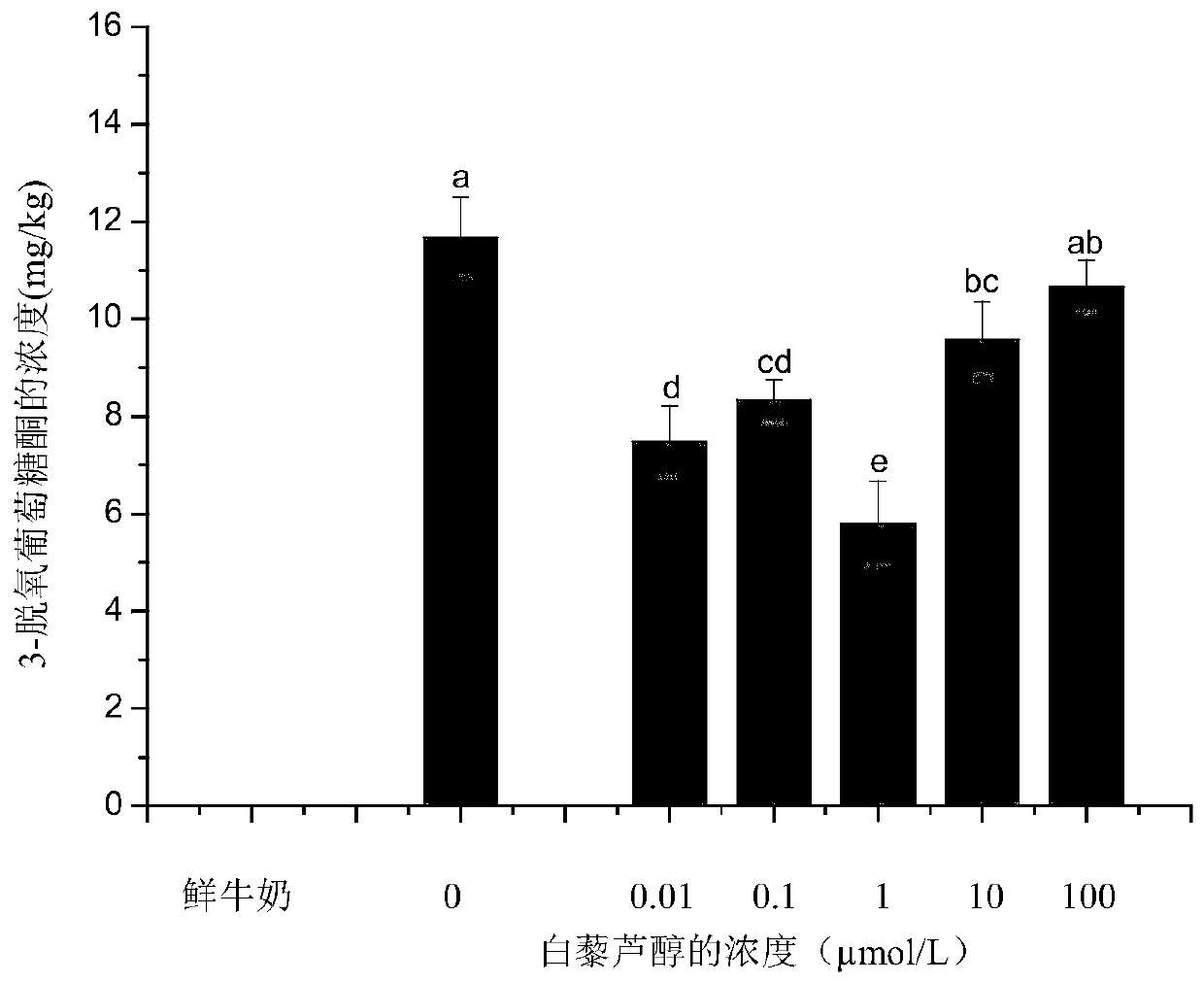

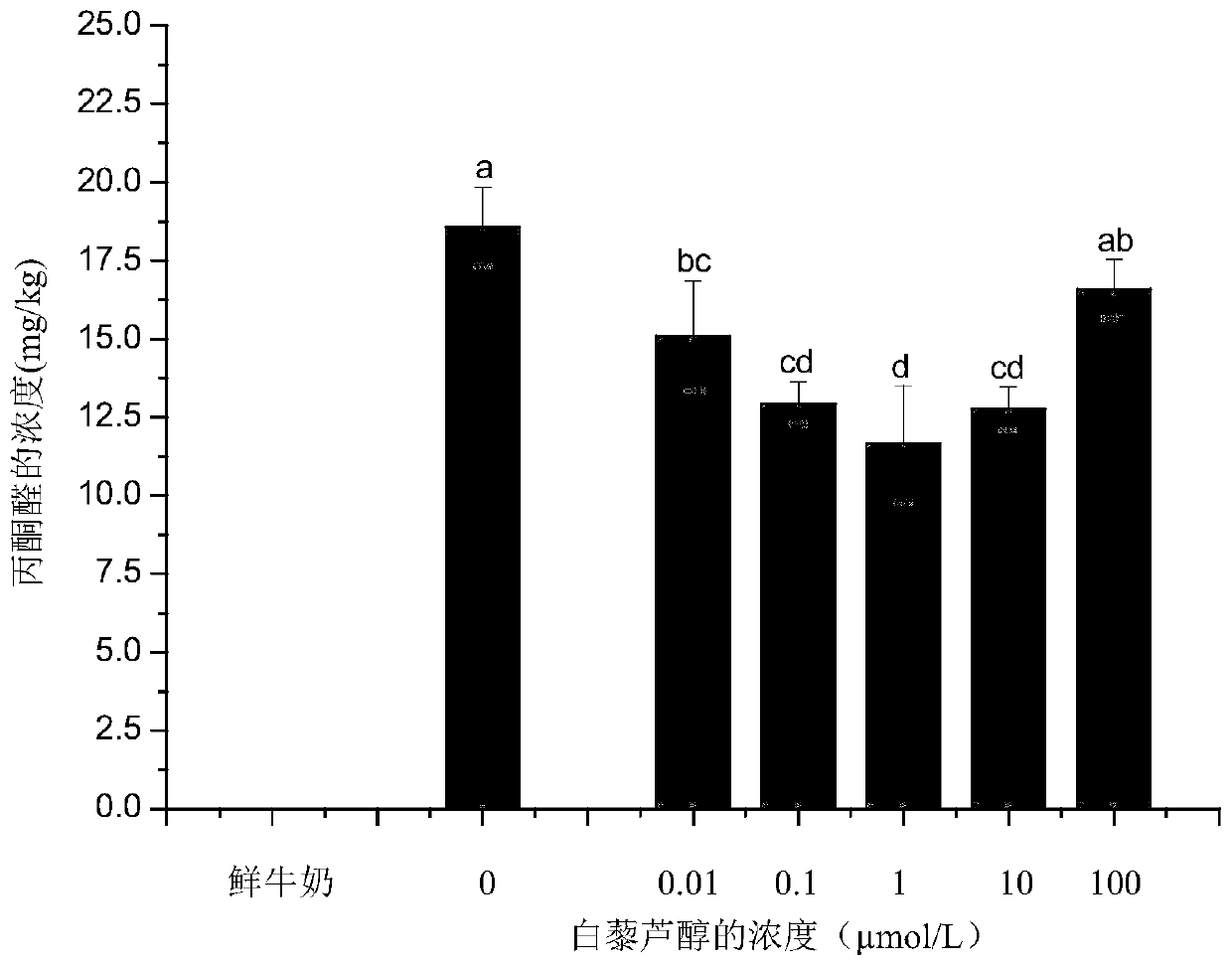

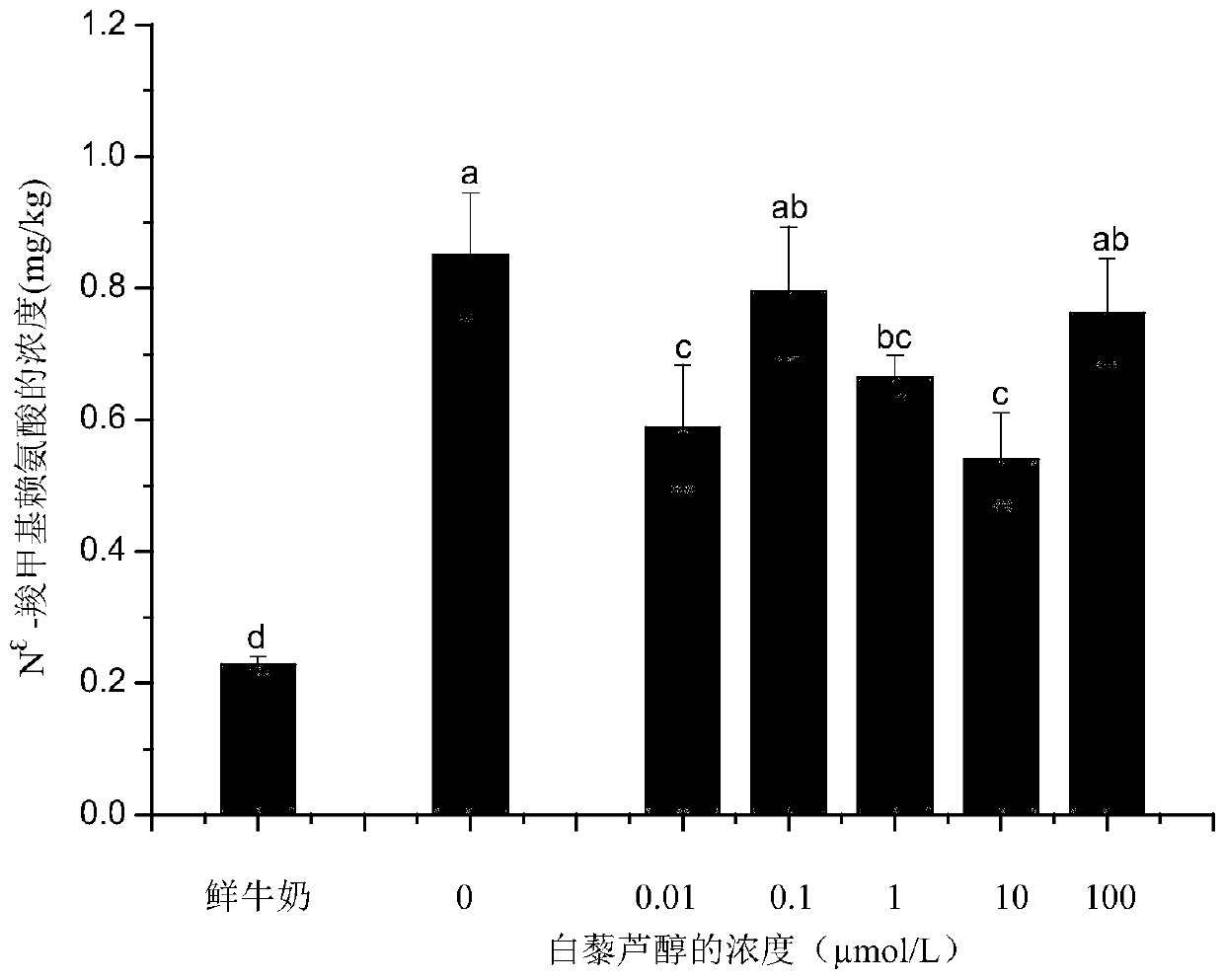

[0061] (1) Add reducing sugar, protein powder and resveratrol into fresh milk, and fully stir (stirring speed is 800r / min, stirring time is 60s) to obtain mixed raw milk;

[0062] (2) Carry out browning and high-temperature sterilization treatment on the raw milk mixed in step (1), wherein browning conditions: keep at 98°C for 2.5 hours, stir for 30s every 30 minutes; sterilization conditions: sterilization temperature at 85°C, sterilize The time is 300s, and the fermentation raw material is obtained;

[0063] (3) Cool the fermentation raw materials in step (2) to 42°C at room temperature, and then add a compound starter at a fermentation temperature of 42°C and a fermentation time of 7 hours to obtain brown yoghurt;

[0064] (4) Place the brown yoghurt obtained in step (3) at 4° C. for 10 h, refrigerate, cook, and stir to break the e...

Embodiment 2

[0069] A method for preparing charcoal-fired yoghurt with low content of advanced glycation end products, the operation steps are as follows:

[0070] (1) Add reducing sugar, protein powder and resveratrol into fresh milk, and fully stir (stirring speed is 800r / min, stirring time is 60s) to obtain mixed raw milk;

[0071] (2) Carry out browning and high-temperature sterilization treatment on the raw milk mixed in step (1), wherein browning conditions: keep at 95°C for 3 hours, stir for 30s every 30 minutes; sterilization conditions: sterilization temperature at 95°C, sterilization time 200s, get the fermentation raw material;

[0072] (3) Cool the fermentation raw materials in step (2) to 40°C at room temperature; then add a compound starter, ferment at 40°C, and ferment for 8 hours to obtain brown yoghurt;

[0073] (4) Place the brown yoghurt obtained in step (3) at 4°C for 12 hours, refrigerate, cook, and then stir to break the emulsion (stirring speed is 250r / min, stirring...

Embodiment 3

[0078] A method for preparing charcoal-fired yoghurt with low content of advanced glycation end products, the operation steps are as follows:

[0079] (1) Add protein powder, reducing sugar and resveratrol into fresh milk, and fully stir (stirring speed is 800r / min, stirring time is 60s) to obtain mixed raw milk;

[0080] (2) Carry out browning and high-temperature sterilization treatment on the raw milk mixed in step (1), wherein browning conditions: keep at 96°C for 3 hours, stir for 30s every 30 minutes; sterilization conditions: sterilization temperature at 90°C, sterilization time 250s to obtain the fermentation raw material;

[0081](3) Cool the fermentation raw materials in step (2) to 41°C at room temperature; then add a compound starter, ferment at a temperature of 43°C, and ferment for 6 hours to obtain brown yoghurt;

[0082] (4) Place the brown yoghurt obtained in step (3) at 4° C. for 8 h, refrigerate, cook, and stir for demulsification (stirring speed: 250 r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com