Pneumatic tyre

A technology for pneumatic tires and tires, applied in pneumatic tires, tire parts, vehicle parts, etc., can solve the problems of sound-absorbing parts peeling, sound-absorbing parts failure, deformation follow-up, etc., to improve static stability, ensure sound-absorbing effect, realize The effect of rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

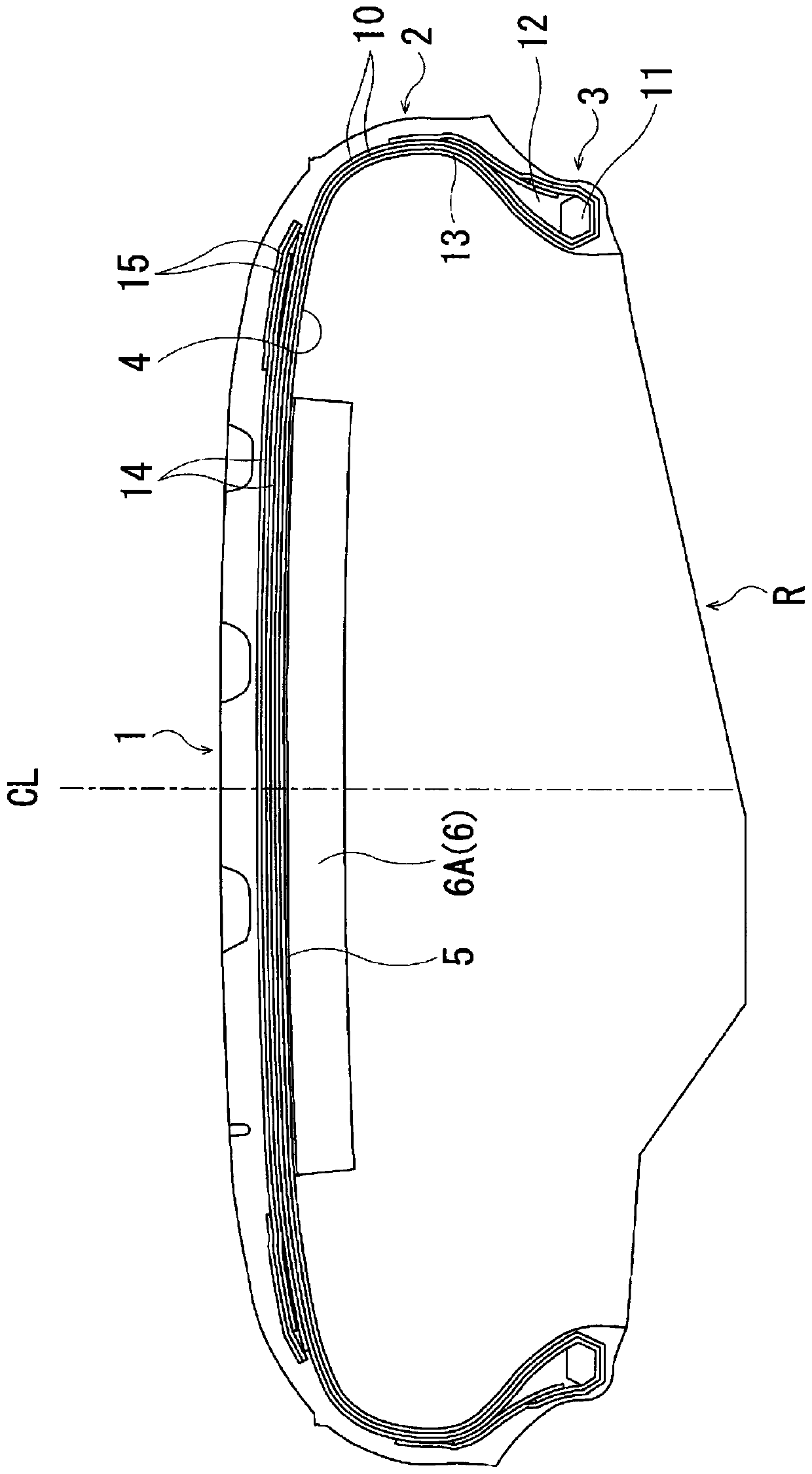

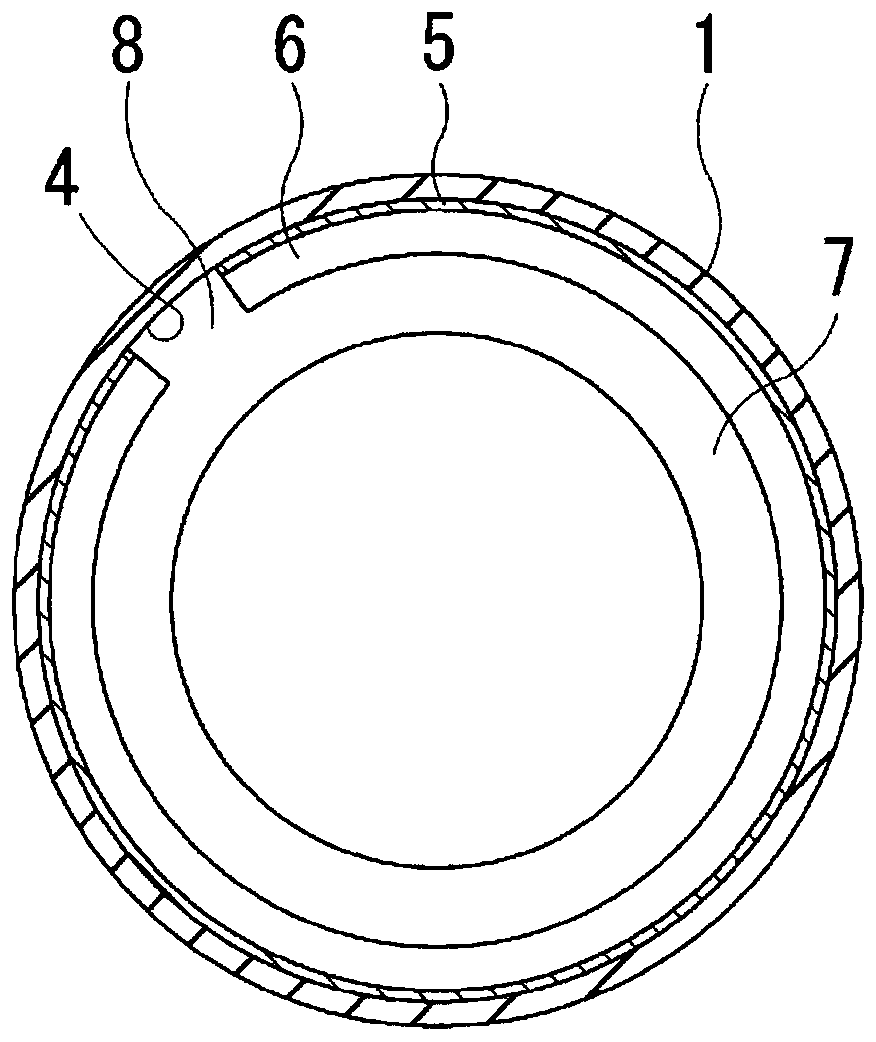

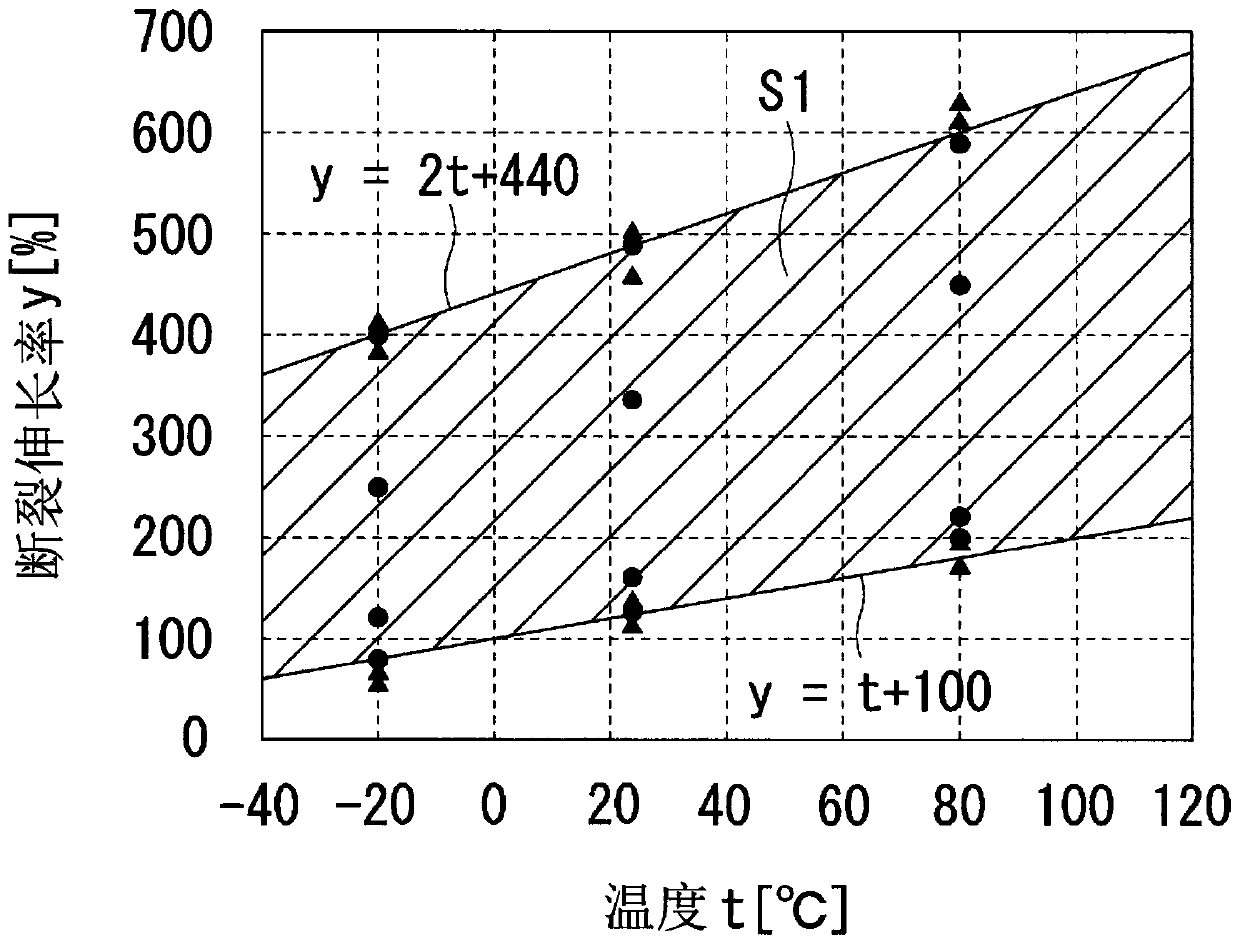

[0049] The tires of Comparative Examples 1 to 4 and Examples 1 to 4 were produced. The tire size of the pneumatic tire was 275 / 35ZR20, and it was provided with: a tread portion extending in the tire circumferential direction in an annular shape; On both sides of the tread portion; and a pair of bead portions, arranged on the inner side of the tire radial direction of these sidewall portions, and the sound absorbing members A to H having different physical properties are placed on the inner surface of the tread portion along the tire circumferential direction through the adhesive layer And paste. In addition, for the sound absorbing materials A to H attached to each test tire, the hardness of the sound absorbing materials was set as in Table 1 [N / 314cm 2 ], density of sound-absorbing parts [kg / m 3 ] and the number of units of sound-absorbing parts [pcs / 25mm].

[0050] In these test tires, the elongation at break [%] of each of the sound absorbing materials A to H was measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com