Synthesis method of 3-methyl-4-nitrodibenzofuran

A synthetic method, nitro technology, applied in the direction of organic chemistry, etc., can solve the problems of unfavorable industrial production preparation, low reaction yield, high price, etc., and achieve the effect of avoiding expensive raw materials, simple synthetic method, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

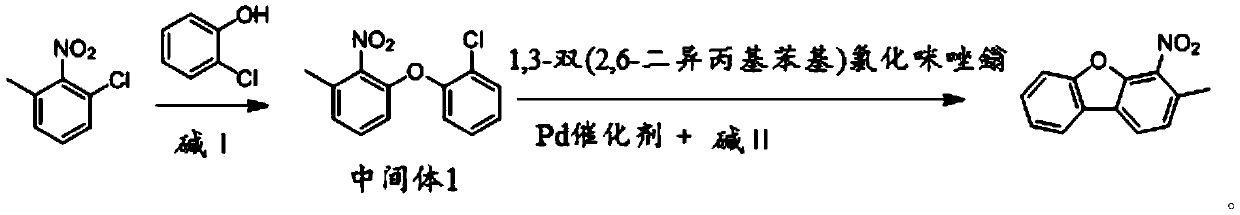

[0025] The invention provides a kind of synthetic method of 3-methyl-4-nitro-dibenzofuran, comprising the following steps:

[0026] S1, o-chlorophenol reacts with base I to form a salt, and then reacts with 2-nitro-3-chlorotoluene to obtain mixture I through nucleophilic substitution reaction, and intermediate 1 is obtained from mixture I after post-treatment;

[0027] S2. Dissolve intermediate 1 and 1,3-bis(2,6-diisopropylphenyl) imidazolium chloride in an aprotic polar solvent, and carry out intramolecular close under the action of Pd catalyst and base II Ring reaction to obtain mixture II, which is post-treated to obtain 3-methyl 4-nitro-dibenzofuran;

[0028] Its synthetic route is as follows:

[0029]

Embodiment 1

[0032] A kind of synthetic method of 3-methyl-4-nitro-dibenzofuran, specifically comprises the following steps:

[0033] first step:

[0034]

[0035] Under the protection of an inert gas, add 1896g of 50% KOH aqueous solution to the reaction bottle, dropwise add 1890g of o-chlorophenol in an ice-water bath, add 1700g of 2-nitro-3-chlorotoluene after the dropwise addition and stir at room temperature for 1 hour, and raise the temperature to 150°C React 30h and stop heating. Cool down to 60°C, add 22000ml of methylcyclohexane and stir for 0.5h, filter, and wash the filtrate with hot water until neutral. The organic phase was concentrated at 103°C under normal pressure, the residue was distilled, and the main fraction was recrystallized from methylcyclohexane to obtain 1627.6g of intermediate 1 with a yield of 62.3% and GC>99.3%.

[0036] Step two:

[0037]

[0038] Under the protection of an inert gas, add dimethylacetamide (DMAc) 1000ml to the reaction flask, intermed...

Embodiment 2

[0040] A kind of synthetic method of 3-methyl-4-nitro-dibenzofuran, specifically comprises the following steps:

[0041] first step:

[0042]

[0043] Under the protection of an inert gas, add 810 g of 50% KOH solution to the reaction flask, add 770 g of o-chlorophenol (1.3) dropwise under ice bath, add 800 g of 2-nitro-3-chlorotoluene after stirring at room temperature for 1 h after the addition, and heat up React at 160°C for 24h and stop heating. Cool down to 50°C, add 5000ml of methylcyclohexane and stir for 0.5h, filter, and wash the filtrate with hot water until neutral. The organic phase was concentrated at 82°C under normal pressure, the residue was distilled, and the main fraction was recrystallized with methylcyclohexane to obtain 736.8 g of intermediate 1 with a yield of 59.93% and GC>99.0%.

[0044] Step two:

[0045]

[0046] Under the protection of an inert gas, add 600ml of DMA, 300g of intermediate I, 315g of potassium carbonate, 5.1g of palladium acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com