A servo tool holder for chip breaking and cutting method thereof

A servo tool holder and cutting method technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as pinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

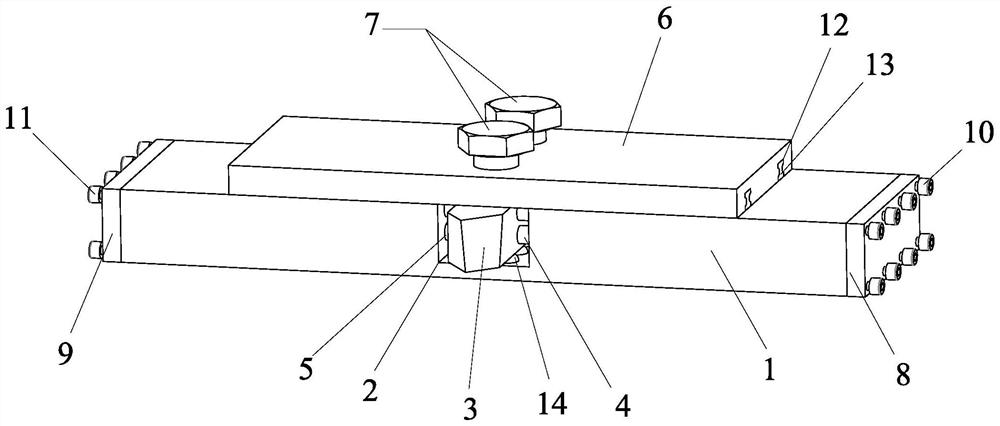

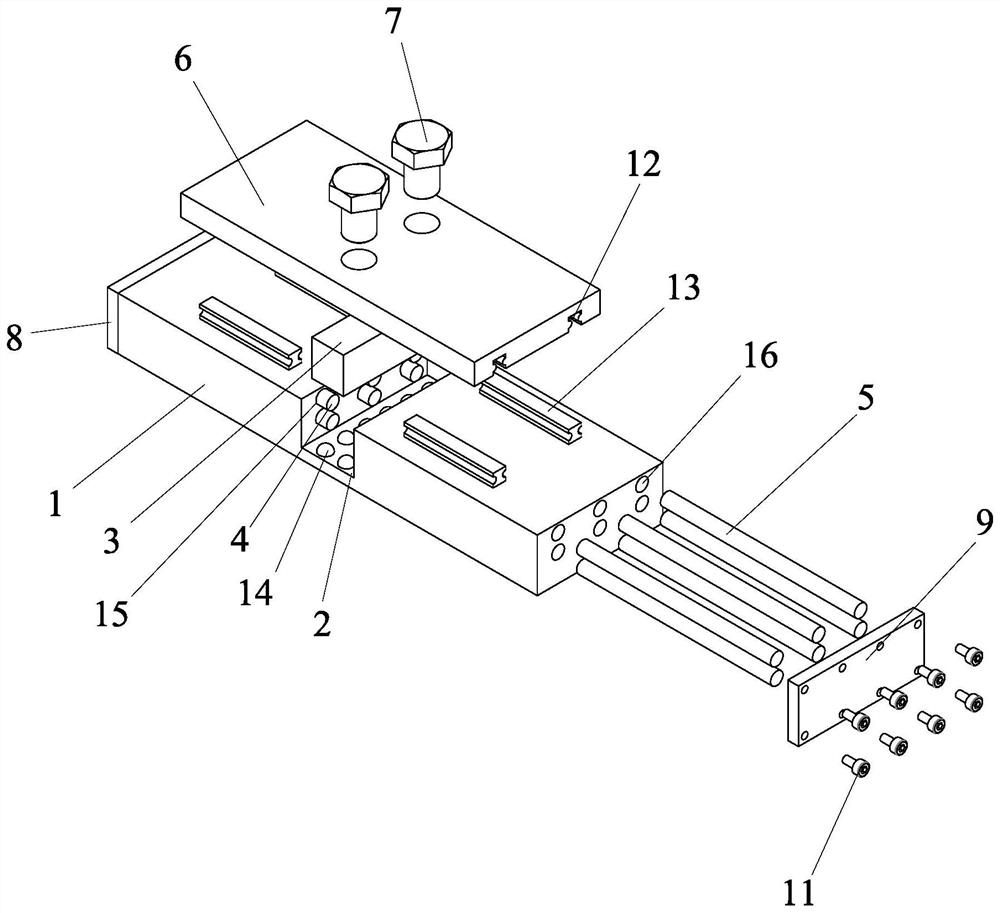

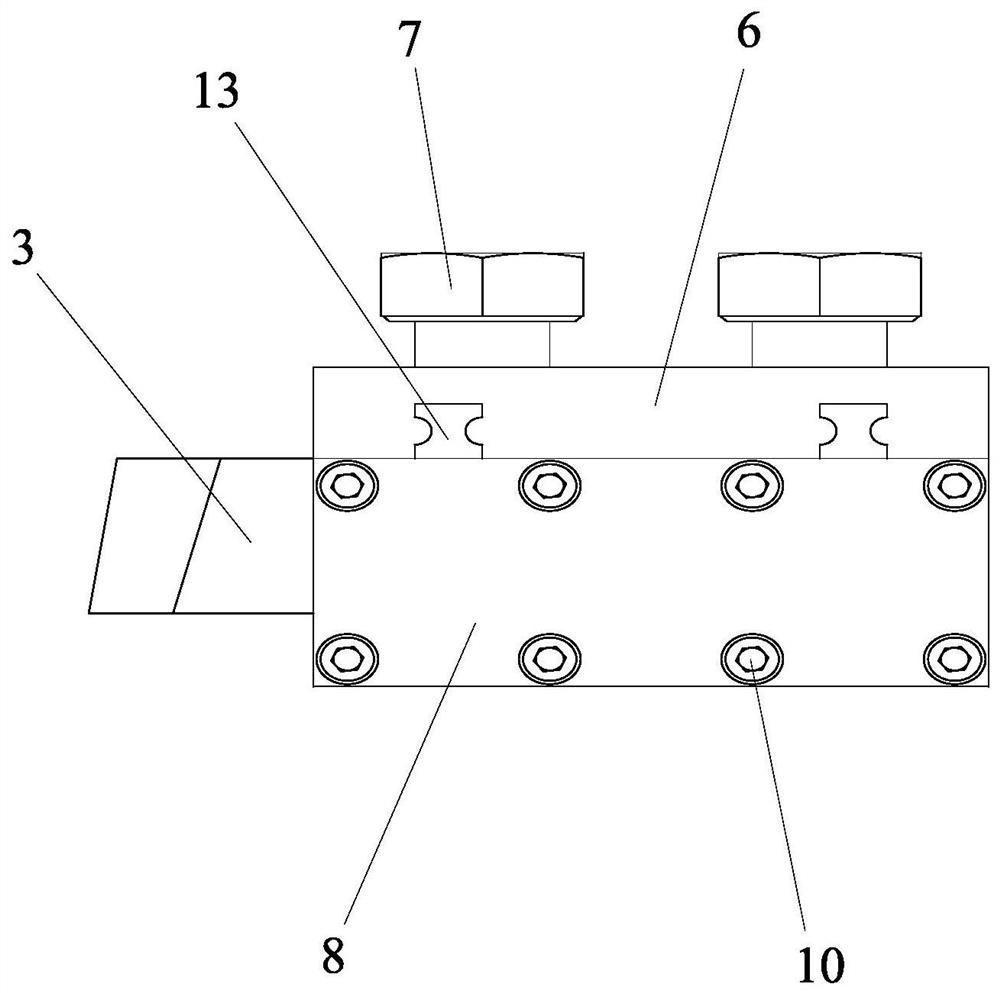

[0033] Embodiment: A kind of servo tool holder for breaking chips, as attached Figure 1-6 As shown, the tool rest body 1 is included, the middle part of the tool rest body 1 is provided with an open slot 2, the open slot 2 is provided with a turning tool 3, and a group of first through holes 15 are respectively opened on the two side walls of the open slot 2 And a group of second through holes 16, the first piezoelectric ceramic driver 4 is installed in the first through hole 15, the second piezoelectric ceramic driver 5 is installed in the second through hole 16, and the first piezoelectric ceramic driver 5 is installed in the first through hole 16. The piezoelectric ceramic driver 4 and the second piezoelectric ceramic driver 5 are respectively against the both sides of the turning tool 3; the top of the tool rest body 1 is slidably connected with an upper cover 6, and the middle part of the upper cover 6 is pierced with a The first pre-tightening bolt 7 on the top of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com