Ultrasonic-assisted vacuum frying kettle for fruits and vegetables

An ultrasonic-assisted vacuum frying technology, which is applied in the field of frying kettles, fruit and vegetable ultrasonic-assisted vacuum frying kettles, can solve the problems of nutrient damage, product overheating, and product burnt, etc., to reduce energy consumption and improve frying efficiency , the effect of reducing the unevenness of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

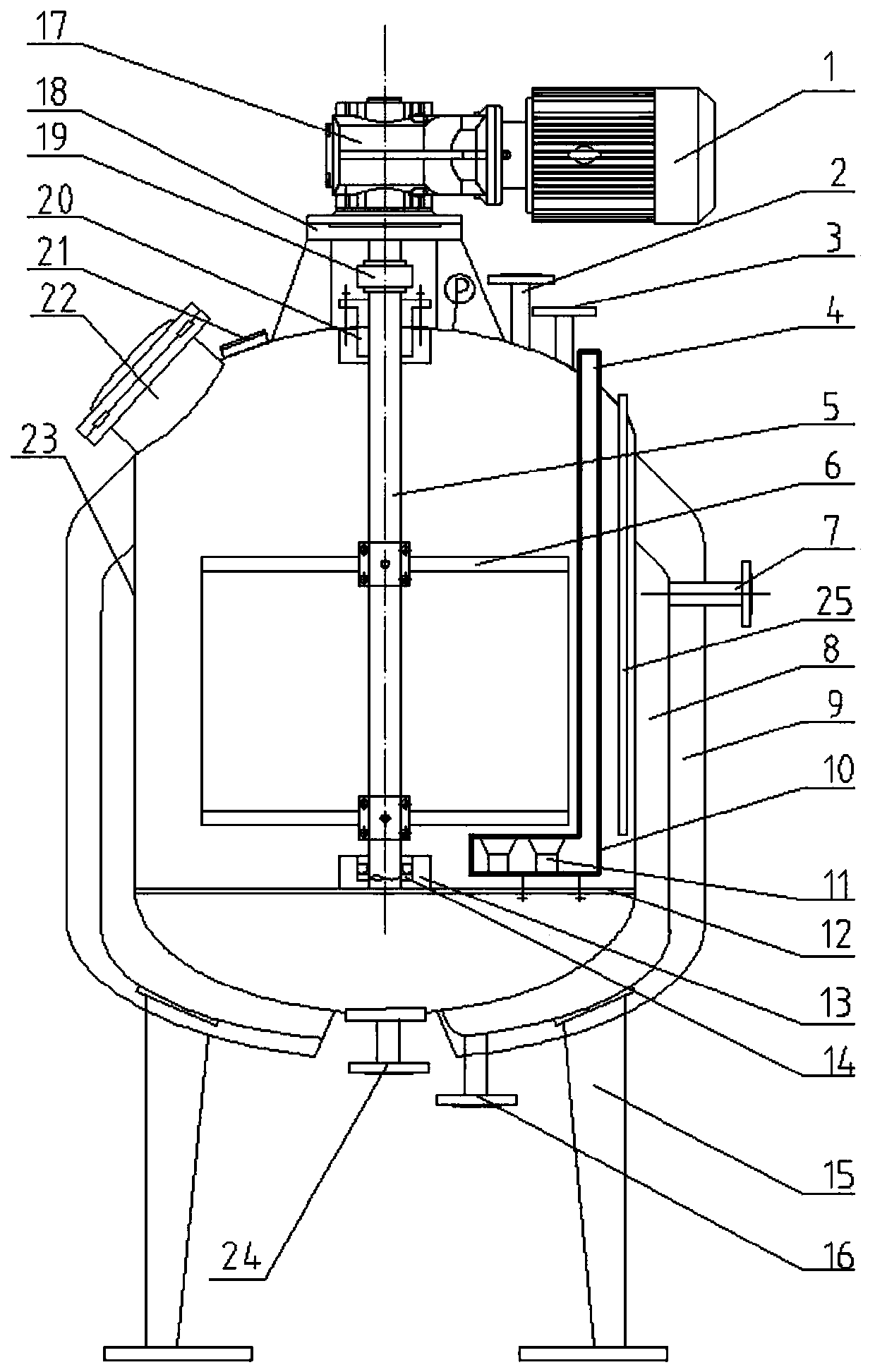

[0021] like figure 1 As shown, a fruit and vegetable ultrasonic-assisted vacuum fryer includes a frequency conversion motor 1, a vacuum interface 2, an oil inlet 3, a metal wire tube 4, a rotating shaft 5, a deoiling basket 6, a heating medium inlet 7, a jacket layer 8, Insulation layer 9, ultrasonic generator 10 (with transducer 11 inside), bracket 12, bearing seat 13, thrust bearing 14, feet 15, heating medium outlet 16, reducer 17, frame 18, coupling 19, packing Sealing device 20, sight glass 21, material inlet and outlet 22, kettle body 23, oil discharge port 24; kettle body 23 is welded with feet 15, standing on the ground; frequency conversion motor 1 is connected with reducer 17 and fixed on kettle body 23 On the frame 18 of the head, a bracket 12 is set at the lower head of the kettle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com