Driving mechanism for lifting type buried transformer

A driving mechanism and lifting technology, which is used in lifting frames, enclosed substations, substations, etc., can solve the problems of inability to extend the piston rod, complex structure, and difficult installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

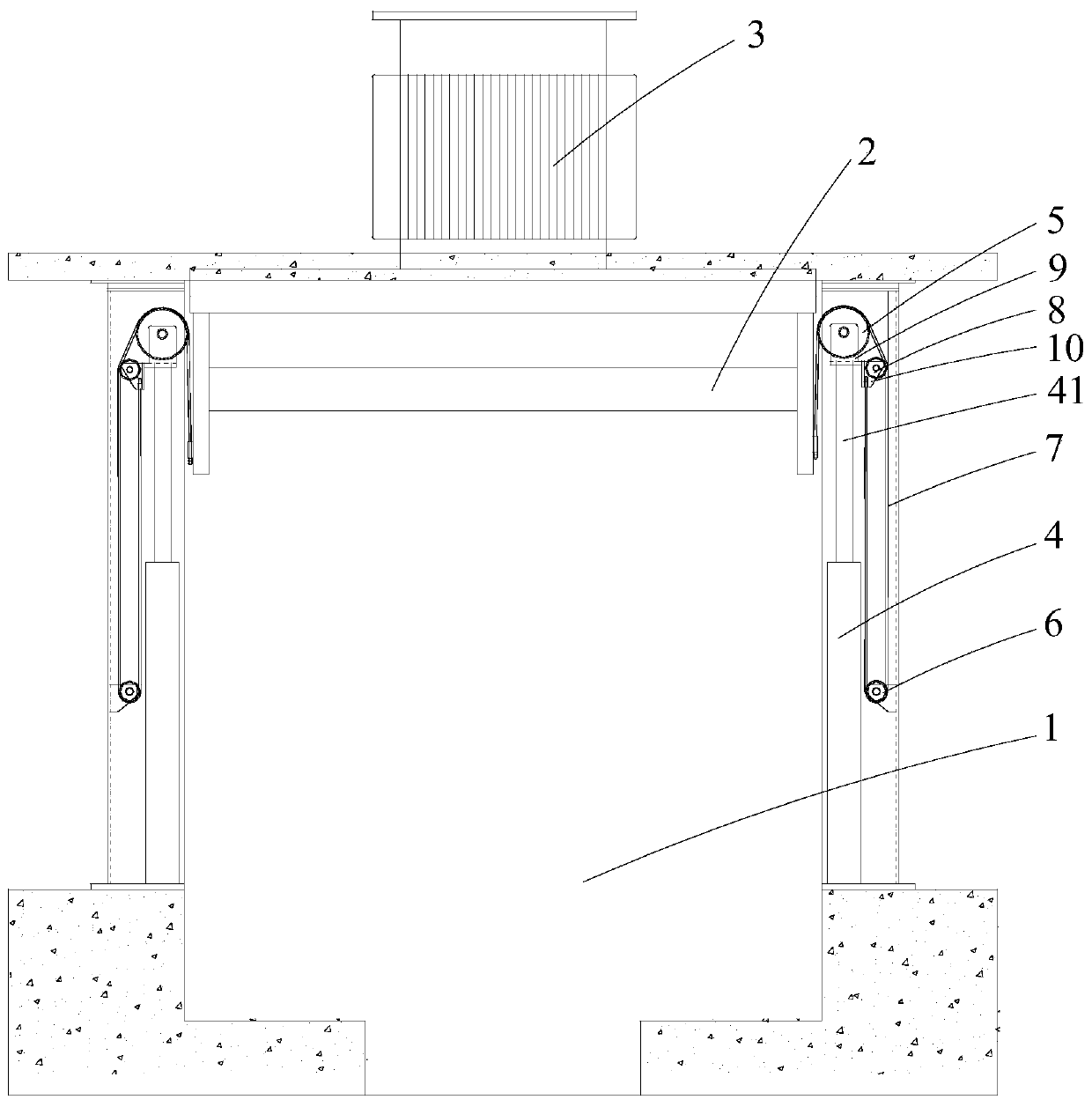

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] The present invention relates to the improvement of the drive mechanism of the lift-type buried substation. The improved drive mechanism uses a power cylinder to drive the load-carrying platform up and down, and has a simple structure and low cost. At the same time, the drive mechanism can overcome the problem of insufficient telescopic stroke of the power cylinder. Effectively increase the driving stroke, so that the cumulative driving stroke matches the lifting stroke of the substation, and can smoothly lift the substation to the ground.

[0021] Specifically, see Figure 1-3 As shown, a lift-type buried substation is shown, which includes a liftable bearing platform 2 located in the pit 1, a substation 3 located on the bearing platform 2, and a power station for driving the bearing platform 2 to go up and down. Drive mechanism. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com