Composite coating diaphragm for lithium ion battery and lithium ion battery

A lithium-ion battery and composite coating technology, which is applied to secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc., can solve the problems of low hardness of the diaphragm, poor safety, short circuit of the battery, etc. Achieve high safety performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

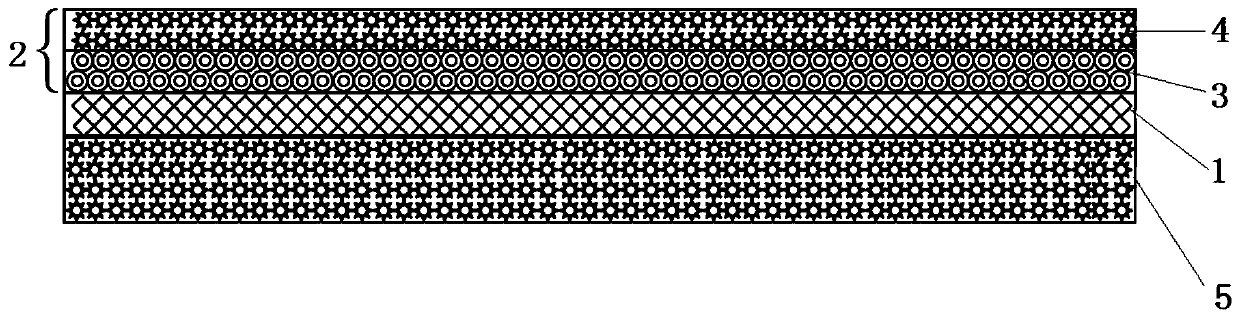

[0032] The lithium-ion battery of the present embodiment uses the composite coating diaphragm, as figure 1 As shown, it includes a diaphragm substrate 1 and a composite coating 2 disposed on one side of the diaphragm substrate 1; the composite coating 2 includes a silica coating 3 disposed on the diaphragm substrate 1 and a silica coating 3 disposed on the silica coating 3 The first boehmite coating 4 on the top; the lithium-ion battery composite coating separator also includes a second boehmite coating 5 disposed on the other side of the separator substrate 1 . The separator substrate was an unmodified PE film with a thickness of 9 μm; the thickness of the silica coating was 2.5 μm, and the thickness of the first boehmite coating was 1.0 μm. The thickness of the second boehmite coating was 3.0 μm. The particle size of the silica in the silica coating is 0.1 μm, the particle size of the boehmite in the first boehmite coating is 2.2 μm, and the particle size of the boehmite in...

Embodiment 2

[0035] The composite coating separator for lithium ion batteries of this embodiment differs from Example 1 of the composite coating separator for lithium ion batteries only in that the thickness of the silicon dioxide coating is 3.0 μm, and the thickness of the first boehmite coating is The thickness is 0.5 μm, the thickness of the second boehmite coating is 3.5 μm, the particle size of silicon dioxide in the silica coating is 1.2 μm, and the particle size of boehmite in the first boehmite coating is 0.1 μm, the particle size of boehmite in the second boehmite coating is 2.2 μm.

[0036] The preparation method of the composite coating separator for lithium ion batteries in this embodiment is the same as that in Example 1 of the composite coating separator for lithium ion batteries.

Embodiment 3

[0038]The lithium-ion battery composite coating diaphragm of the present embodiment comprises a diaphragm substrate and a composite coating disposed on one side of the diaphragm; the composite coating comprises a silica coating disposed on the diaphragm substrate and a silica coating disposed on the silica coating The first boehmite coating on the layer; the lithium-ion battery composite coating diaphragm also includes a second boehmite coating disposed on the other side of the diaphragm substrate. The separator substrate is an unmodified PE film with a thickness of 9 μm; the thickness of the silica coating is 2.5 μm, the thickness of the first boehmite coating is 1.0 μm, and the thickness of the second boehmite coating is 3.0 The particle size of the silica in the μm silica coating is 1 μm, the particle size of the boehmite in the first boehmite coating is 1.2 μm, and the particle size of the boehmite in the second boehmite coating is 0.1 μm.

[0039] The preparation method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com