Optical fiber hydrogen sensor based on core/shell nano periodic linear array plasma metamaterial

A nanowire array, plasma technology, applied in the fields of nanotechnology, analytical materials, nanotechnology for materials and surface science, can solve the problems of low measurement accuracy and sensitivity of optical hydrogen sensors, and achieve convenient remote monitoring, huge Market potential, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

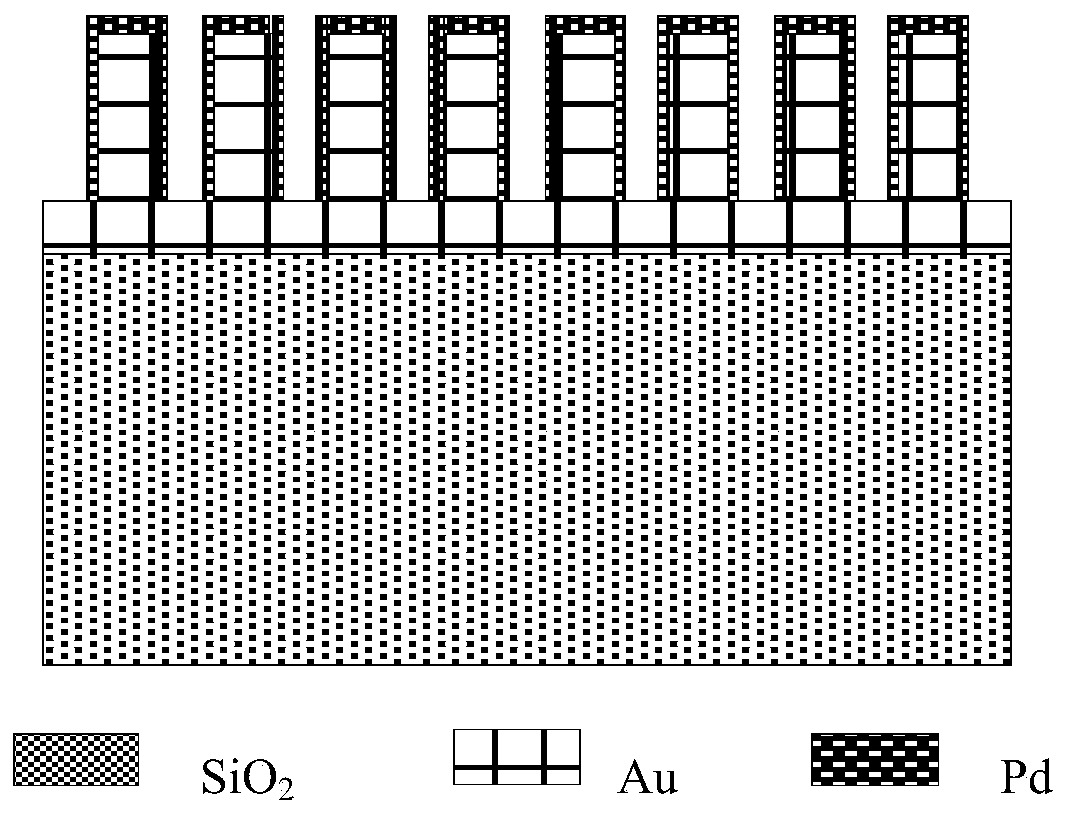

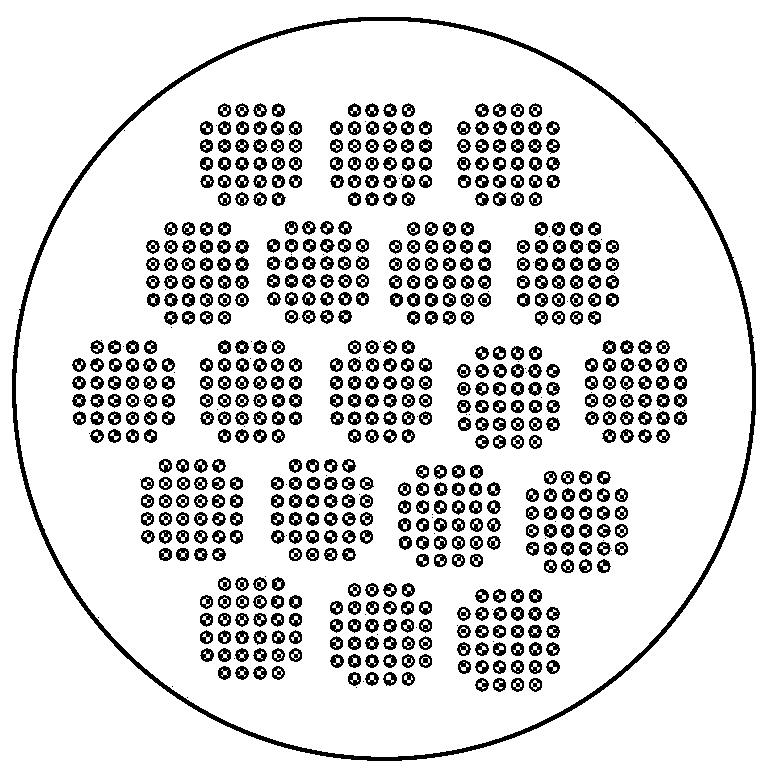

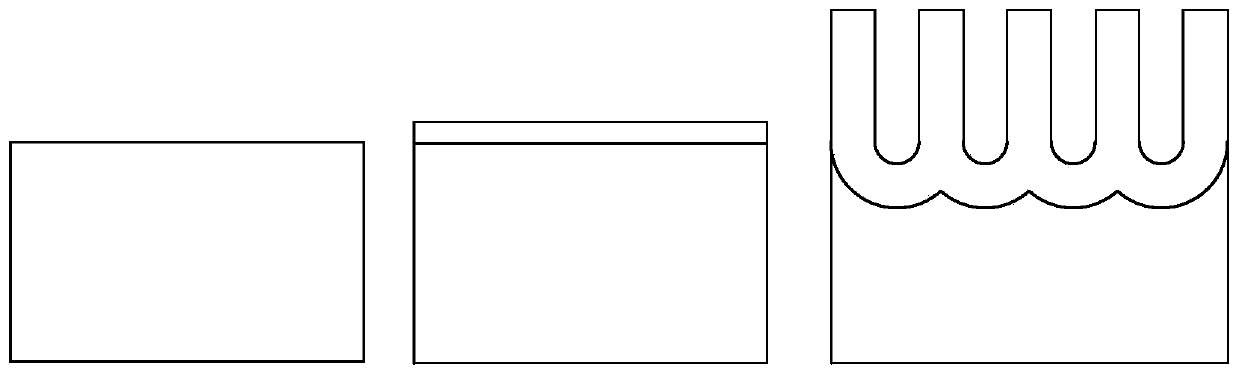

[0032] A fiber-optic hydrogen sensor based on core / shell nano-periodic line array plasmonic metamaterials, its cross-sectional view is shown in figure 1 shown. The optical fiber hydrogen sensor structure mainly includes an optical fiber and a patterned gold core / palladium shell nanowire array on the end surface of the optical fiber. Its main production process is: deposit gold and aluminum on the end surface of the optical fiber, form a porous alumina structure through anodic oxidation process, corrode the diameter of the enlarged hole and fill it with gold to form gold nanowires, and form a composite of alumina gold nanowires with the alumina structure film, and palladium-plated around or on the end of the gold nanowires to form a gold-palladium composite structure; Etching removes the gold-palladium composite nanowire structure that is not masked by polystyrene nanospheres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com