Nuclear power plant water storage tank liquid level switch calibration device and method

A liquid level switch and calibration device technology, applied in the direction of testing/calibration devices, measuring devices, liquid/fluid solid measurement, etc., can solve the problems of increasing test cost, increasing test water, different filling and draining rates, etc., to improve calibration Test work efficiency and reduce human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0055] For the convenience of explanation, the relevant structure of the water storage tank of the nuclear power plant is firstly introduced.

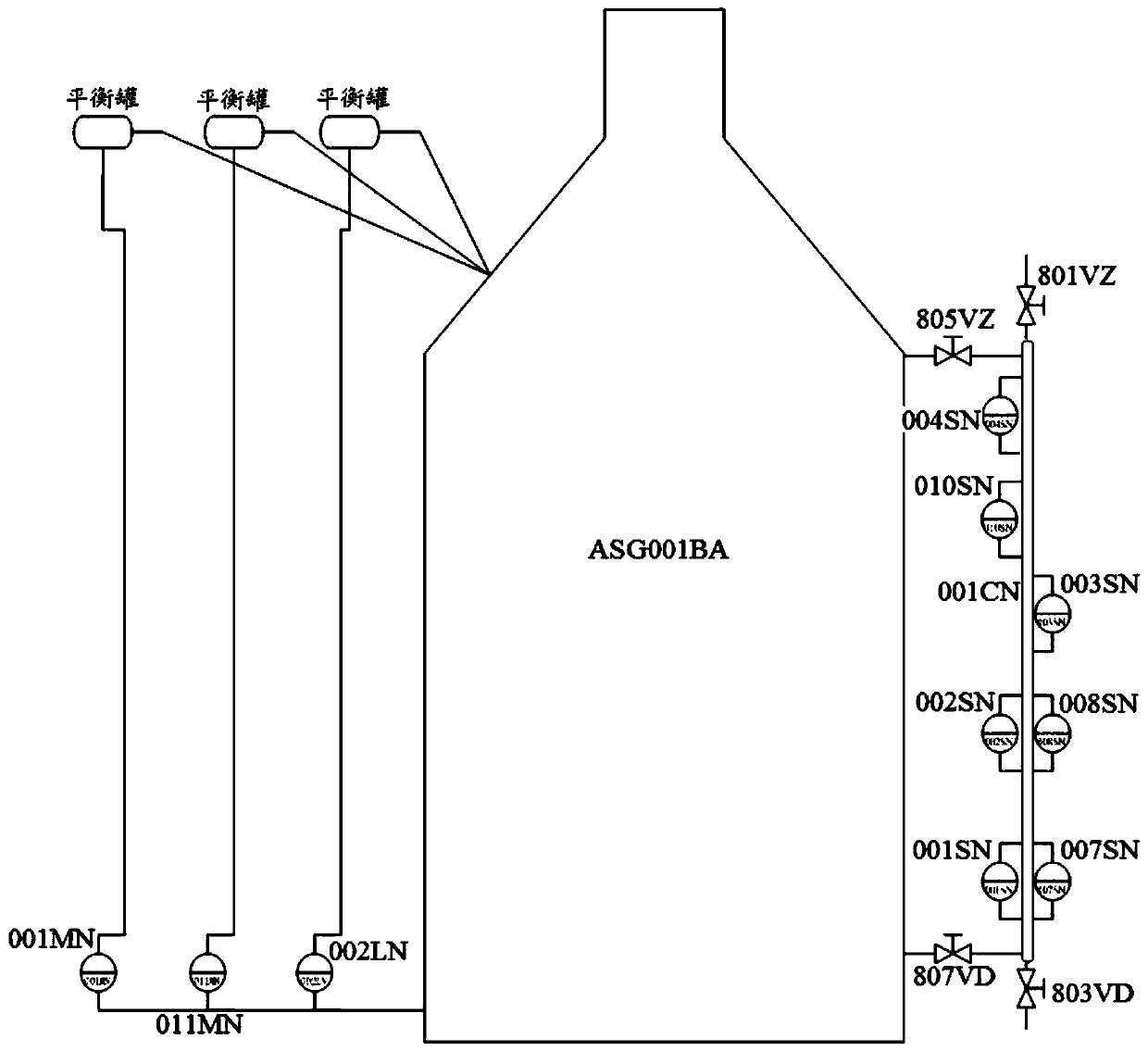

[0056] see figure 2 , the nuclear power plant water storage tank ASG001BA is equipped with liquid level column 001CN and multiple liquid level monitoring meters 001MN, 002MN, 011MN, 002LN, multiple liquid level switches 001SN, 002SN, 003SN, 004SN, 007SN, 008SN, 010SN to be verified Set on the liquid level column 001CN. A valve 805VZ is provided on the pipeline connecting the top of the liquid level colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com