Cascade energy-storage type air source heat pump direct-condensation floor heating system

An air source heat pump, direct condensing technology, applied in heating systems, heating methods, heat storage equipment, etc., can solve the problems of low energy storage density of storage water tanks, reduce operating costs, occupy indoor space, etc., and save heat storage. The effect of water tank space, reducing power consumption and prolonging heat release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

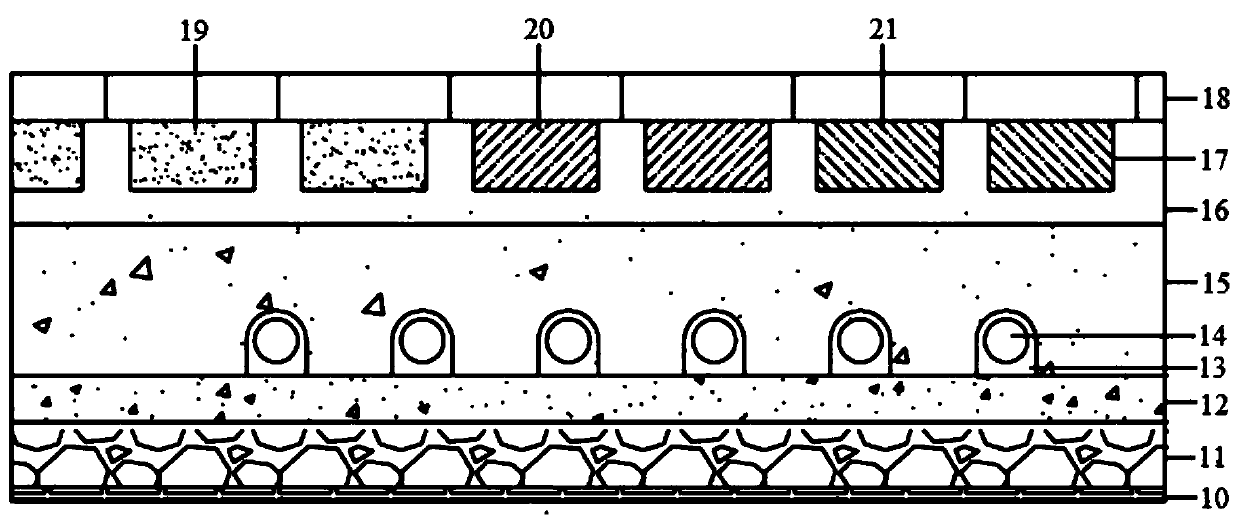

[0023] Such as figure 1 Shown is a structural schematic diagram of a cascaded energy storage type air source heat pump direct-condensing floor heating system of the present invention. The system includes an evaporator 1 , a four-way reversing valve 2 , a gas-liquid separator 3 , a compressor 4 , a solenoid valve 5 , a cascade phase change floor 6 , a liquid reservoir 7 , a filter 8 and an expansion valve 9 . Wherein, the input end of the compressor 4 communicates with the output end of the gas-liquid separator 3 . Both sides of the input and output ends of the expansion valve 9 are provided with filters 8 to ensure that the air source heat pump can prevent impurities from entering the compressor no matter it is in the heating or defrosting mode. The four ports of the four-way reversing valve 2 communicate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com