Double-layer intercommunicating water supply valve of ceramic closing element

A technology of water supply valve and ceramic valve core, which is applied to engine components, sliding valves, valve devices, etc., can solve problems such as affecting production efficiency, occupying production time, and cumbersome and inconvenient disassembly and removal process, and achieves good practicability and convenient disassembly. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

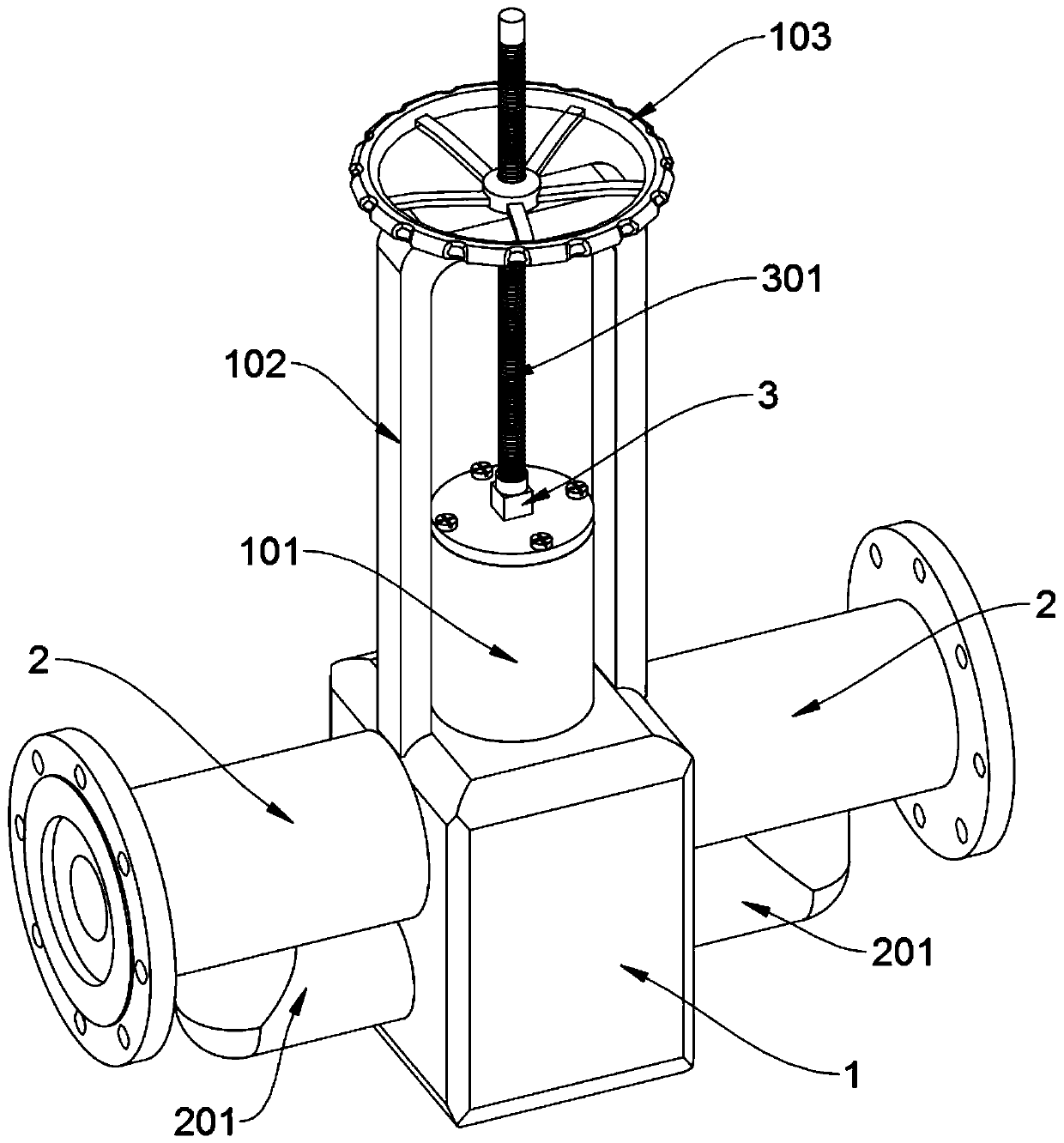

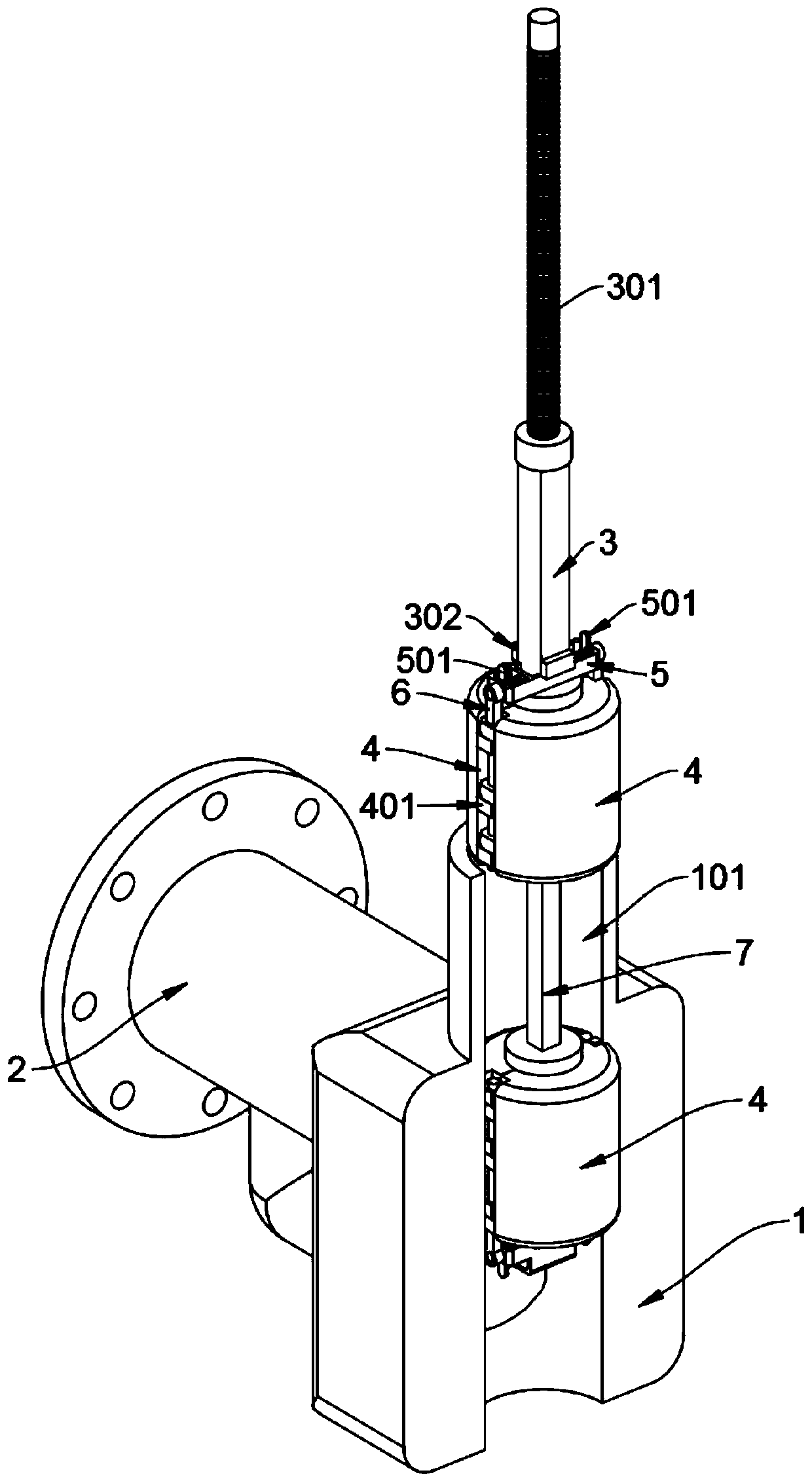

[0030] see Figure 1 to Figure 10 , an embodiment provided by the present invention: a double-layer intercommunicating water supply valve of ceramic closing elements, including a valve body 1, a water pipe 2, a square sleeve rod 3 and a vertical support insertion rod 6, and the valve body 1 includes a valve core Sleeve 101, support frame 102 and hand wheel 103, the valve body 1 is a rectangular structure, and a through shaft hole is opened on it, and a valve core sleeve 101 is welded and supported on the top of the through shaft hole, and the valve core sleeve 101 A circular cover plate is locked and sealed with the bottom of the through shaft hole; a support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com