UV-curing-based iron printing screen printing ink

A technology of printing ink and barbed wire, which is applied in the chemical industry, can solve the problems of easy pollution of the environment when coating thermosetting varnish, and achieve the effect of competitiveness, strong three-dimensional effect and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

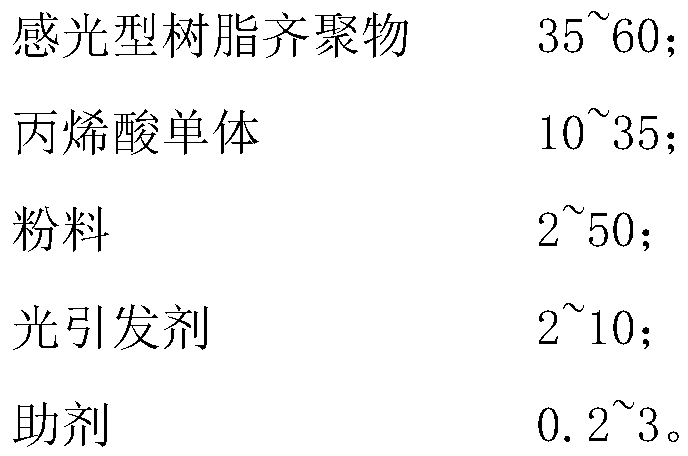

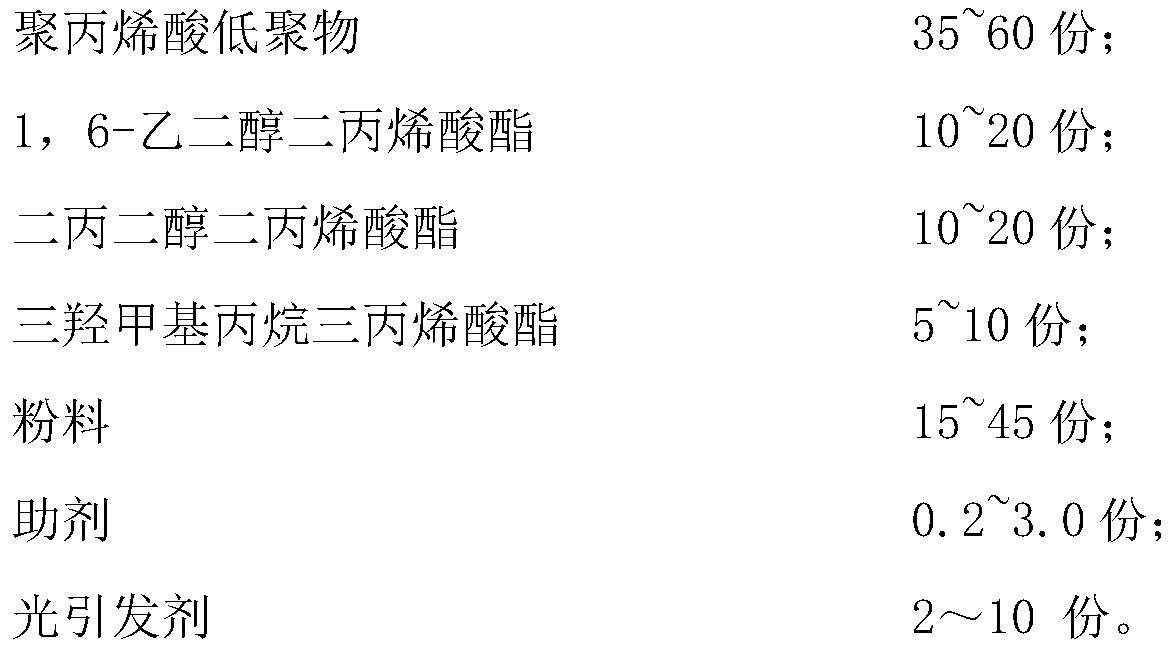

[0021] A kind of printed wire screen printing ink based on UV curing is prepared from the following raw materials in parts by weight:

[0022]

[0023] When preparing UV-curable wire-screen printing ink, first mix the ingredients according to the above-mentioned components and their weight ratio, and then use a disperser and other equipment to mix and stir, so that each component is fully mixed and evenly distributed.

[0024] The prepared UV screen printing ink for printing iron in the present embodiment 1 is printed with 100 mesh polyester screens, adopts 65 degrees of hardness scraping glue, and the printing pressure is 0.5mpa, and is printed on the thermosetting varnish for printing iron, and the curing energy is 500mj / cm 2 , and its performance testing results are shown in Table 1. Thus, a sample for evaluation was prepared.

[0025] According to the template prepared in Example 1, its test results are shown in Table 1.

[0026] Table 1

[0027] project u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com