Mixing device for civil construction

A technology of civil construction and mixing device, which is applied in the directions of mixer, transportation and packaging, dissolution, etc., can solve the problems of inability to transport raw materials in bags, mixing ratio error, etc., and achieve easy reuse, good effect, and easy recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

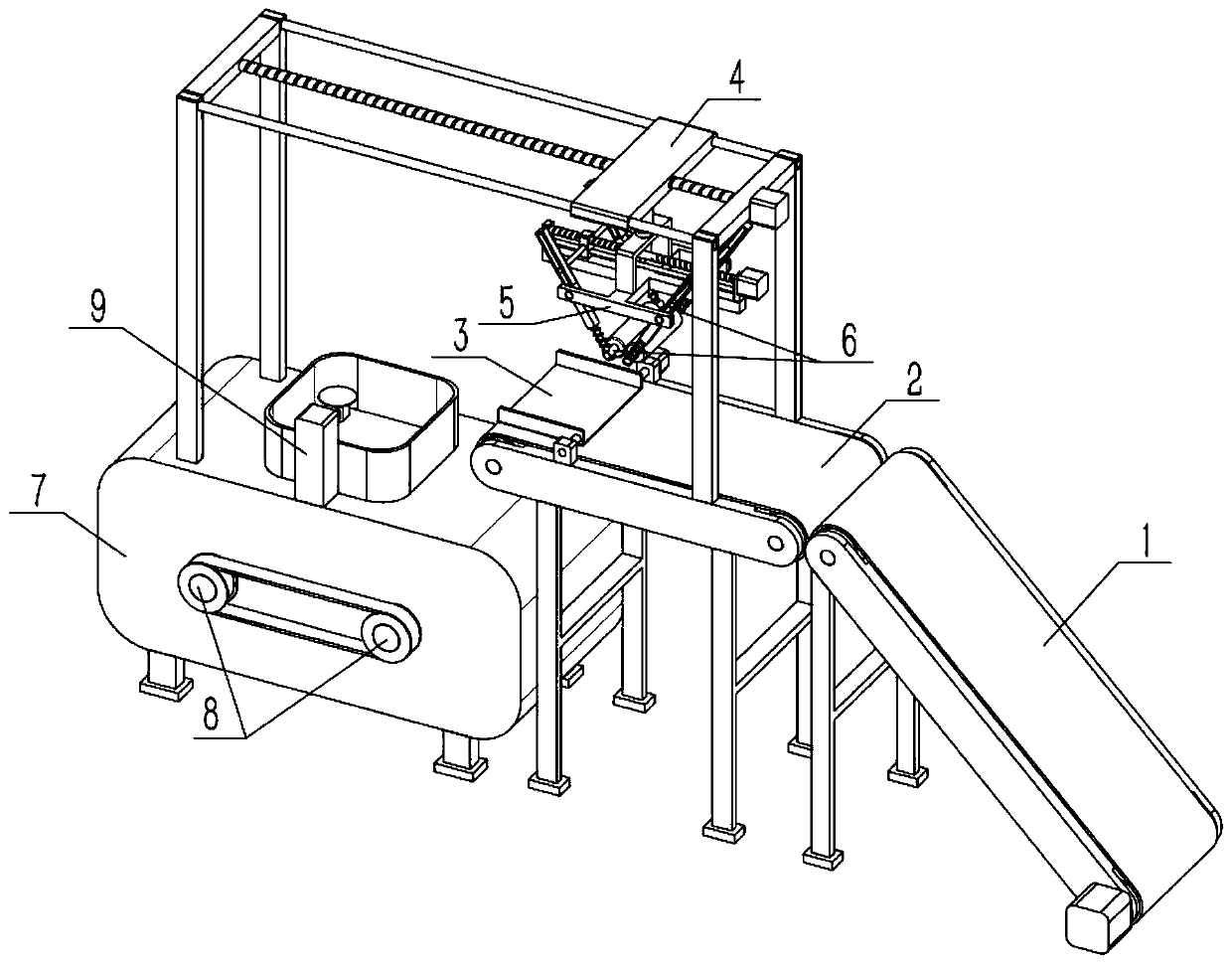

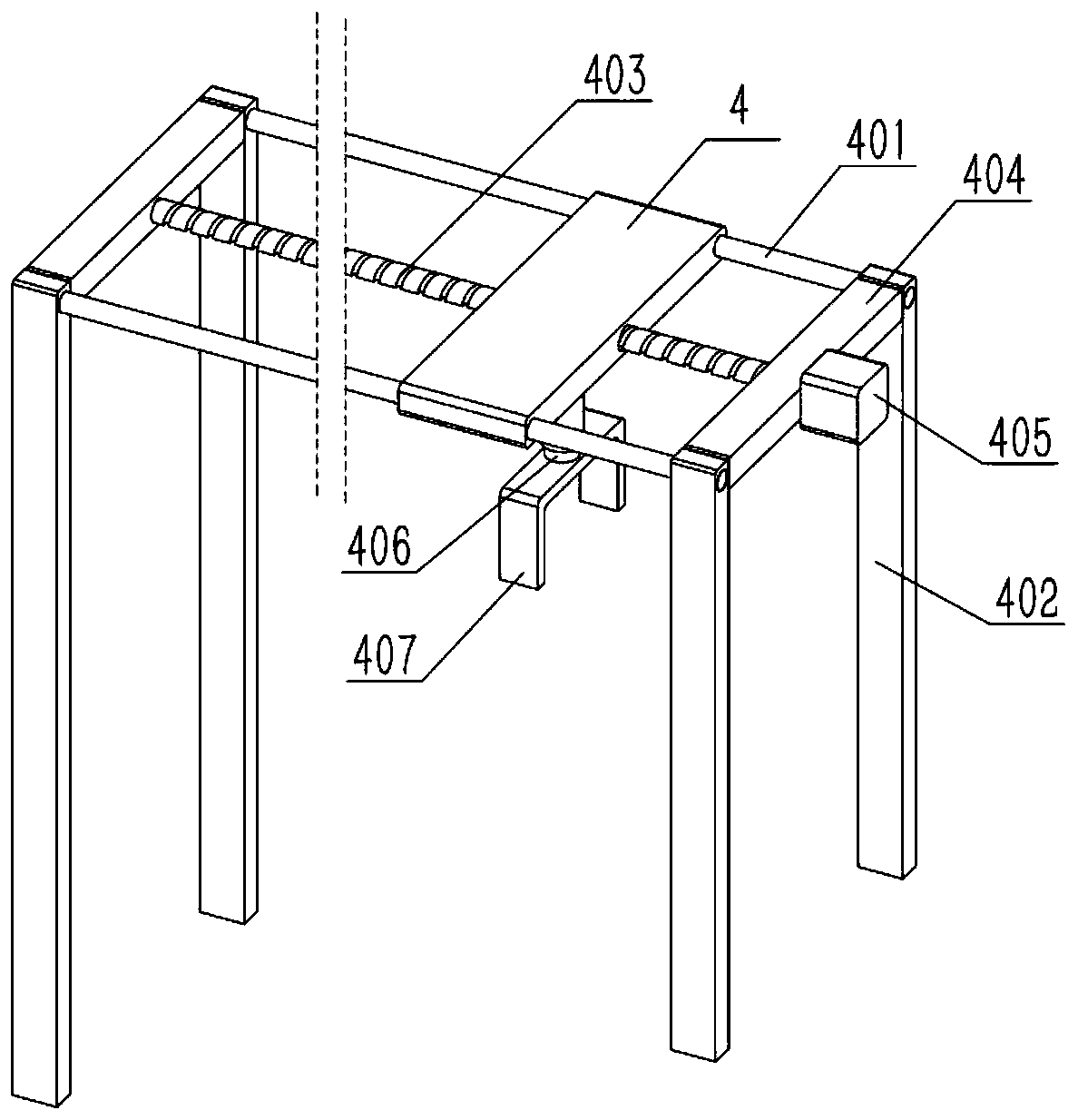

[0029] Such as Figure 1-8 As shown, a mixing device for civil engineering construction includes a housing 7, a shaft IV 8, a stirring blade 801, a motor IV 802, a mounting seat 9, an electric push rod II 901, a motor V 902 and a cutting blade 903. The upper end of the housing 7 is provided with There is a material inlet, and the casing 7 is rotated to connect two shafts Ⅳ8, and the two shafts Ⅳ8 are synchronously connected. The motor Ⅴ902 is fixed on the outer end of the casing 7, and the output shaft of the motor Ⅴ902 is fixedly connected to one of the shafts Ⅳ8. The mounting base 9 Fixed on the shell 7, the electric push rod II901 is fixed on the mounting base 9, the motor V902 is fixed on the movable end of the electric push rod II901, the output shaft of the motor V902 is fixed on the cutting piece 903, and the cutting piece 903 is located on the directly above the inlet. The stirring blade 801 is used to stir the materials in the shell 7, for example, mixing the raw mat...

specific Embodiment approach 2

[0031] Such as Figure 1-8 As shown, the mixing device for civil engineering construction also includes a belt conveyor I1 and a belt conveyor II2, and the belt conveyor I1 is used to transport the bagged material to the height of the inlet and transport it to the On the conveyor II2, the belt conveyor II2 is used to transport the bagged material to the side of the inlet. refer to figure 1 Place the wide side of the bagged raw material from front to back and the long side from left to right on the belt conveyor Ⅰ1, start the belt conveyor Ⅰ1 to drive the bagged raw material to move to the upper left until it moves to the belt conveyor Ⅱ2 , start the belt conveyor II 2 to drive the bagged raw materials to move to the left close to the material inlet, so as to realize the automatic transportation of the bagged raw materials according to the expected placement form.

specific Embodiment approach 3

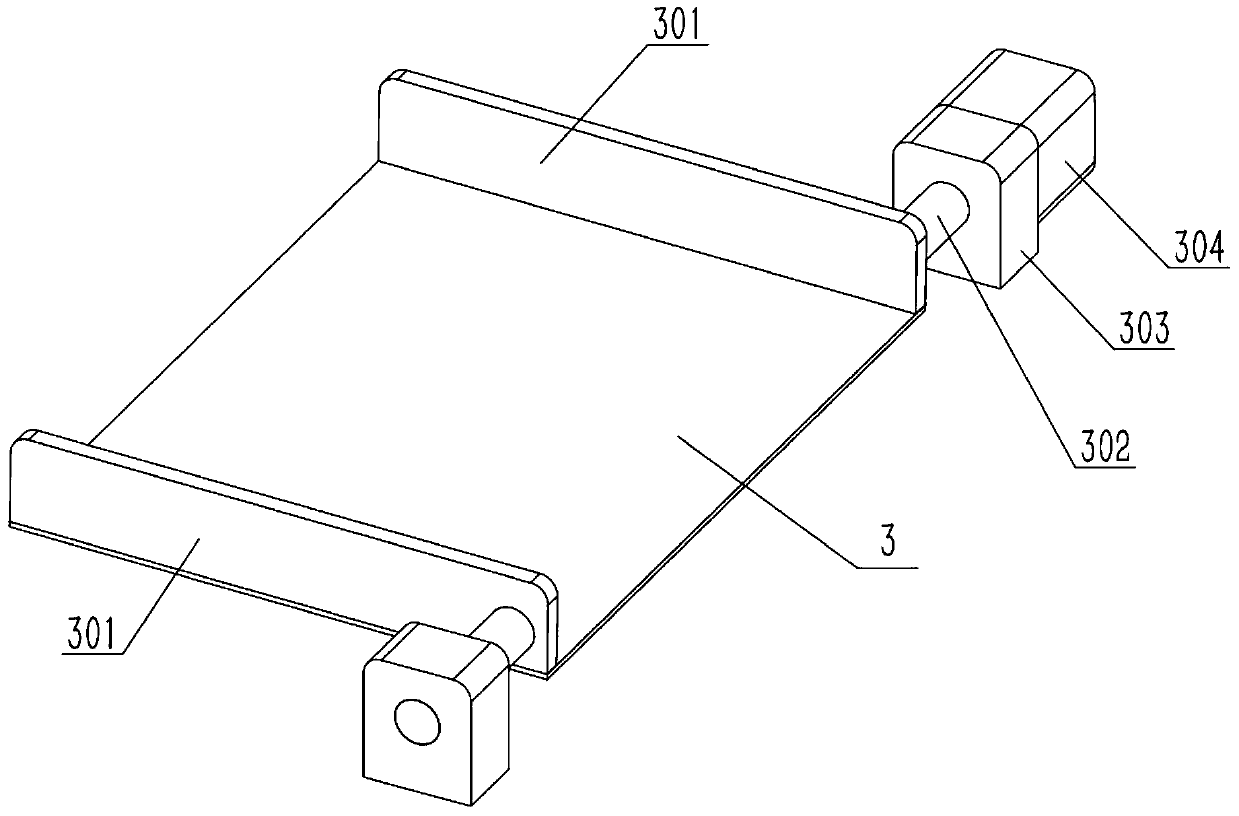

[0033] Such as Figure 1-8As shown, the mixing device for civil engineering construction also includes a half board 3, a rotating part 301, a shaft I302, a shaft seat I303 and a motor I304, and the front and rear ends of the half board 3 are respectively fixed with a rotating part 301 and two The outer ends of the rotating part 301 are fixedly connected with a shaft I302, and the two shafts I302 are located at the right end of the half plate 3. The two shafts I302 are respectively connected to the two shaft seats I303 in rotation, and the motor I304 is fixedly connected to one of the shaft seats I303. , the output shaft of the motor I304 is fixedly connected to one of the shafts I302; the half plate 3 is arranged on the upper end of the belt conveyor II2 and is arranged close to the inlet, and the distance between the half plate 3 and the belt conveyor II2 is 1 to 5mm. Start the motor I304, the output shaft of the motor I304 drives the shaft I302 to rotate, and the shaft I302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com