Multifunctional environmentally-friendly straw processing equipment

A kind of processing equipment and multi-functional technology, applied in the field of straw processing, can solve the problems of not having the cutting function, not having the function of dust collection, affecting the crushing efficiency, etc., to achieve the effect of ensuring cutting safety, avoiding straw splashing, and ensuring crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

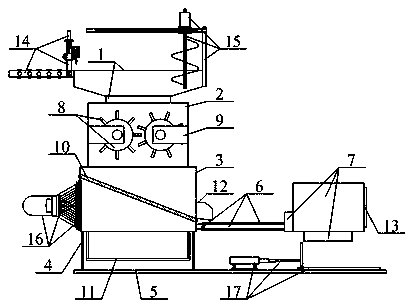

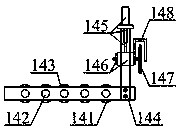

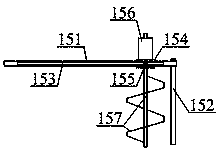

[0041] The present invention is described in detail below in conjunction with accompanying drawings, as shown in accompanying drawing 1 and accompanying drawing 2, multi-functional straw environmental protection processing equipment comprises straw breaking material feeding hopper 1, crushing box 2, straw crushing and separating box 3, support leg 4 , base 5, conveyor belt 6, packaging machine 7, crushing wheel 8, crushing motor 9, separation net 10, collection box 11, export bucket 12, main control machine 13, diversion type straw cutting protection wheel structure 14, anti-clogging Type mobile adjustment rotary machine structure 15, fan structure 16 capable of dust absorption, pollution prevention and environmental protection treatment, and push plate structure 17 after packaging, the lower end of the broken straw feeding hopper 1 is threadedly connected to the entrance of the upper middle position of the crushing box 2 The lower outlet of the crushing box 2 is bolted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com