Method for determining positional errors of drilled holes and securing the drilling process

An error and error calculation technology, applied in program control, general control systems, instruments, etc., can solve the problems of extra investment and operating costs of measuring machines, time staggering, etc., and achieve the effect of cheap setting or optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

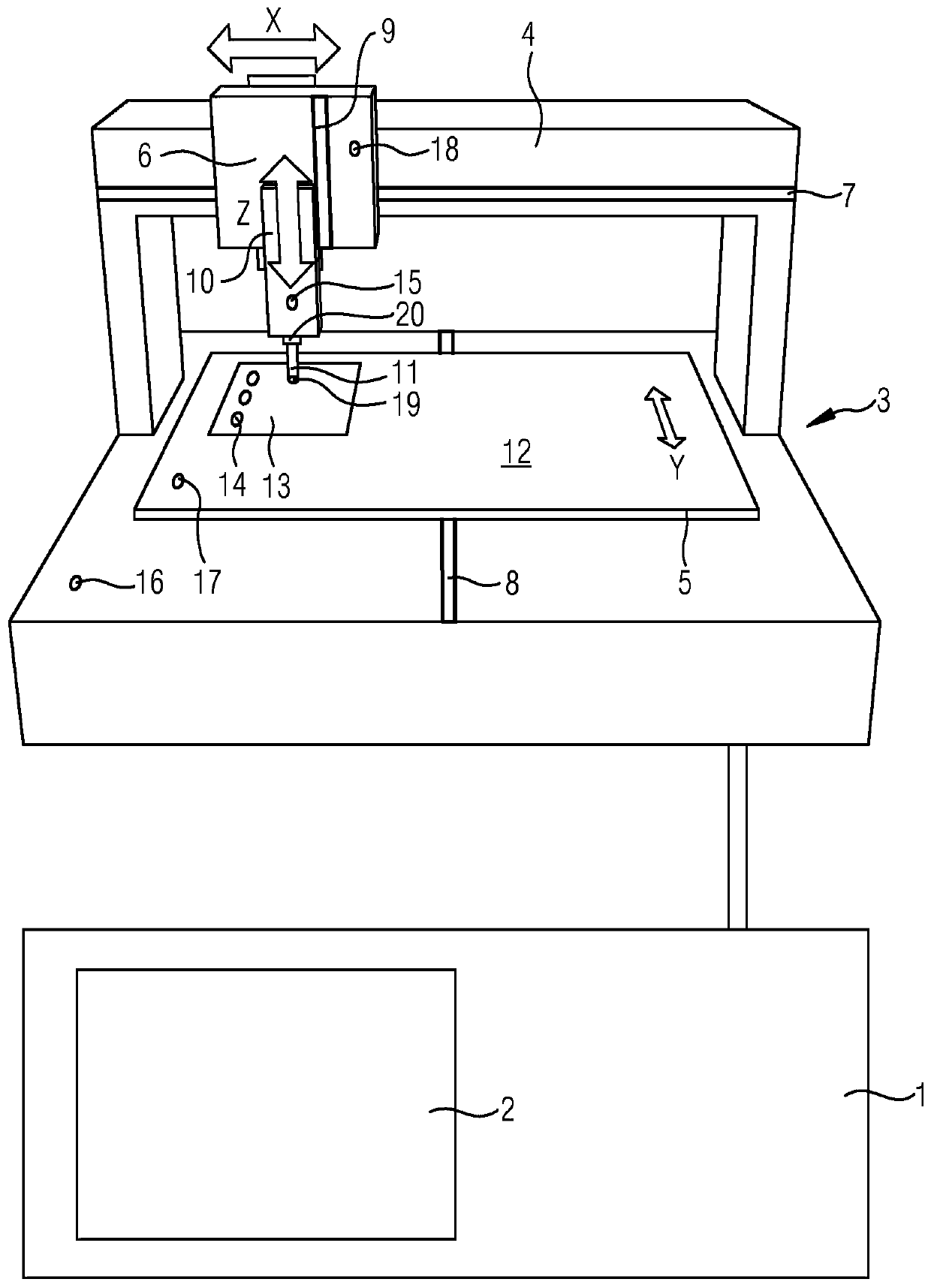

[0031] figure 1 A schematic structure according to the invention for determining a position error of a borehole is shown in a perspective view. A CNC controller 1 with a monitor 2 is connected to a circuit board drill 3 which has three linear drive axes 4, 5, 6, one for the X direction, one for the Y direction and one for the in the Z direction. Designs with more than 3 axes are also possible within the framework of the invention. Each of these drive shafts 4, 5, 6 has absolute measuring, linear displacement sensors 7, 8, 9 in the form of optically scanned steel scales, by means of which the individual drive shafts 4, 5 are detected , 6 the current position. Alternatively, optically scanning glass scales or magnetic length measuring systems can also be used within the framework of the invention. Furthermore, the circuit board drill 3 has a drill shaft 10 fastened to the drive shaft 6 in the Z direction. A drilling tool 11 is fastened in the drill shaft 10 . On the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com