Tissue construct, methods of producing and using the same

A technology of tissue constructs and constructs, applied in biochemical equipment and methods, tissue regeneration, artificial cell constructs, etc., can solve problems that hinder the progress of 3D tissue engineering, embedding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The described method of preparing a tissue construct also includes a step of gelling or fusing the granular tissue.

[0087] In certain embodiments, the step of gelling or fusing the particulate-like tissue includes warming the particulate-like tissue or exposing the tissue to light to induce cross-linking. The term "gelation" refers to the process by which a particle-like structure that can flow under a stress exceeding its yield stress becomes a solid elastic-like structure. This increased interaction can result from the aggregation of the extracellular matrix surrounding the cells or aggregates, and / or through increased cell-cell binding between aggregates (e.g., fusion or use of depletion agents to drive electrostatic interactions) . The gelled granular tissue no longer appears as Bingham fluid and may harden significantly. Therefore, if the cylinder is translated through the material, it will cut the material.

[0088] An exemplary mechanism for gelation is the fusio...

Embodiment 1

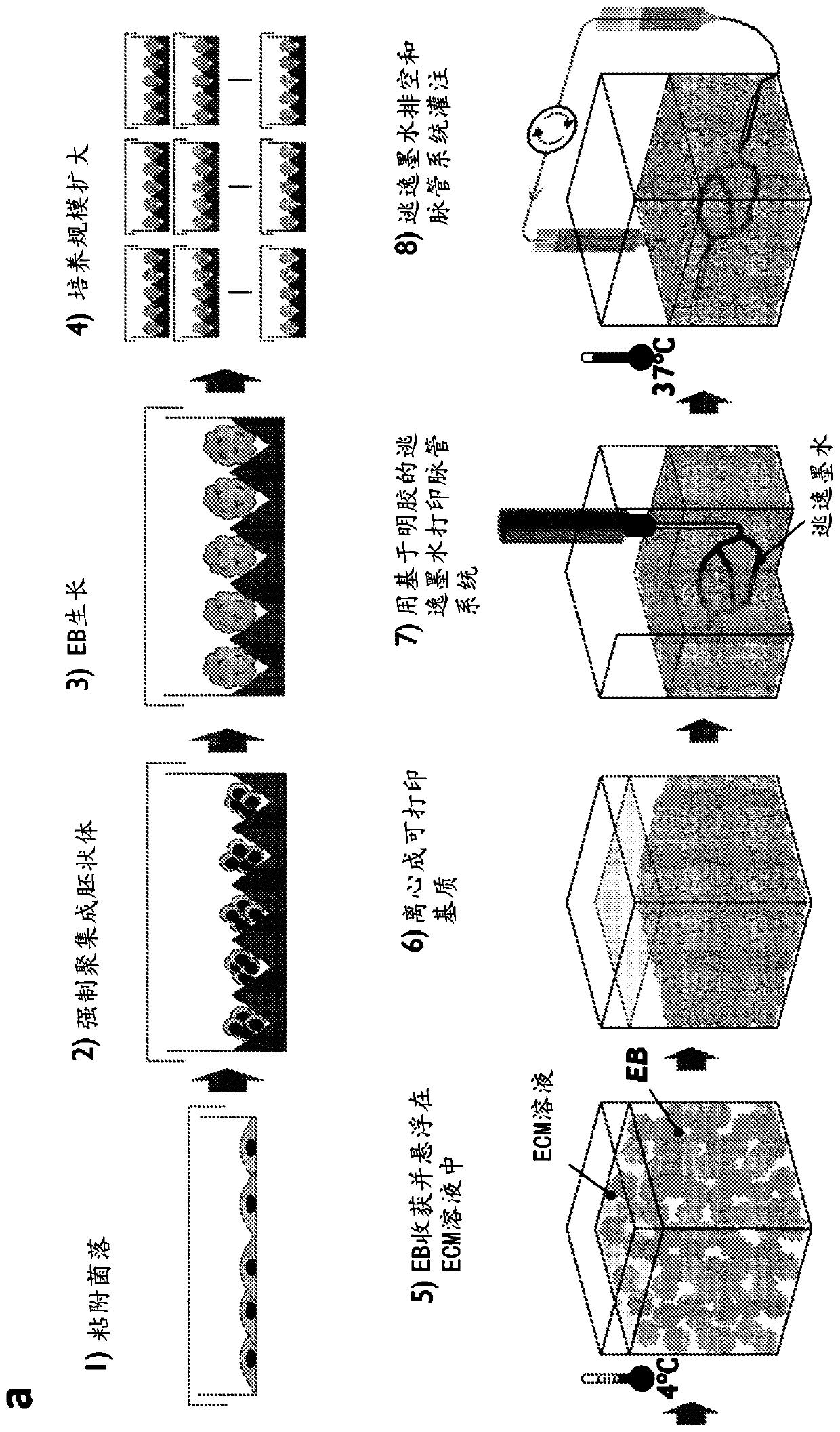

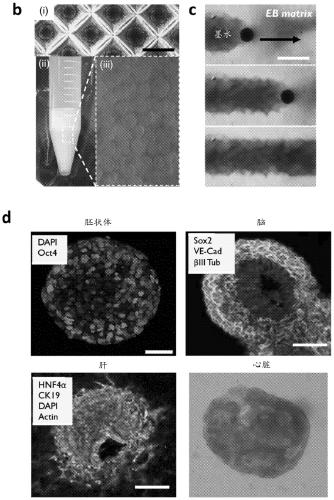

[0174] In order to produce a large number of uniform tissue spheroids, iPSC was transferred to a microwell array to form EB ( figure 1 a). Four days later, these EBs were harvested, mixed with a prepolymer solution of collagen I and Matrigel gel, and compacted by centrifugation to form dense tissue aggregates, which included approximately 200,000,000 cells per 1 mL of tissue ( figure 1 b). Then the sacrificial material is embedded and printed to form a three-dimensional blood vessel network, which can be coupled with an external pump to achieve direct perfusion of oxygen and nutrients to maintain vitality in the entire dense tissue.

[0175] It has been proven that culture scale-up can produce approximately 500 million cell constructs ( figure 1 bi, ii), its particle-like microstructure ( figure 1 biii) Provide sufficient support for the printing of sacrificial filaments, but can yield before translating the nozzle and heal itself in its wake ( figure 1 c). These tissue-like sphe...

Embodiment 2

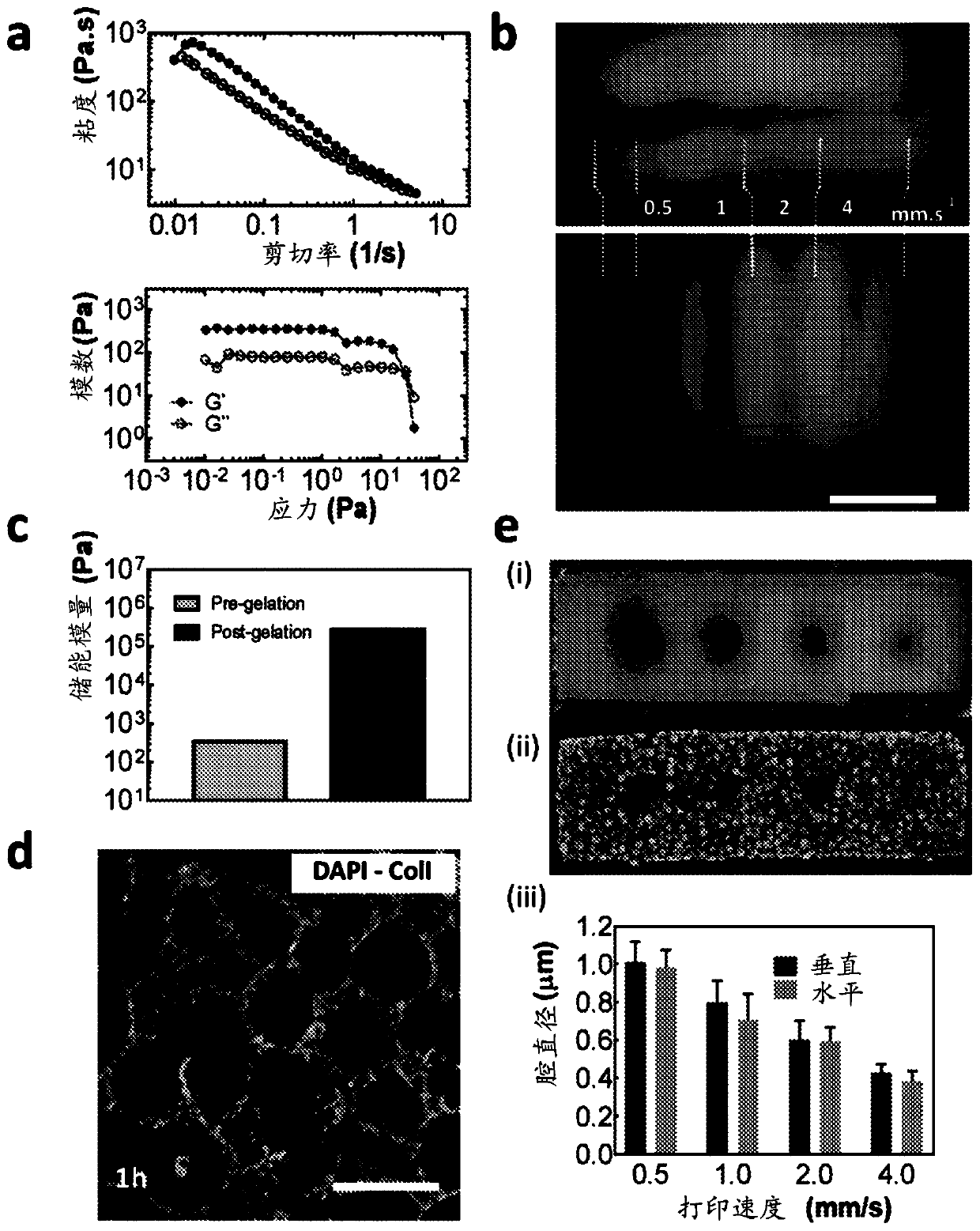

[0177] Quantitatively, embedded printing undergoes shear thinning, thixotropy, and yield stress rheology ( figure 2 a) Realization, capable of supporting embedded 3D printing in both horizontal and vertical directions ( figure 2 b).

[0178] After printing, the tissue was warmed to gel the collagen-matrigel, and significant hardening of the matrix was observed ( figure 2 c), because a fibrous gel is formed in the space around the EB ( figure 2 d). This increased stiffness locks the shape of the printed vasculature and enables pressure-driven flow to penetrate the tissue.

[0179] It is very important for the generation of hierarchical vascular network. While maintaining a constant flow rate of sacrificial material, changing the printing rate makes the blood vessel diameter change smoothly ( figure 2 e) At the same time, it has no adverse effect on the integrity of EBs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com