Digital shot blasting coverage rate measurement method based on computer vision technology

A technology of computer vision and measurement method, applied in the direction of calculation, measurement device, image data processing, etc., can solve the problems of multi-manpower and material resources, time, high measurement cost, low measurement efficiency, etc., and achieve low execution difficulty, low measurement cost, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

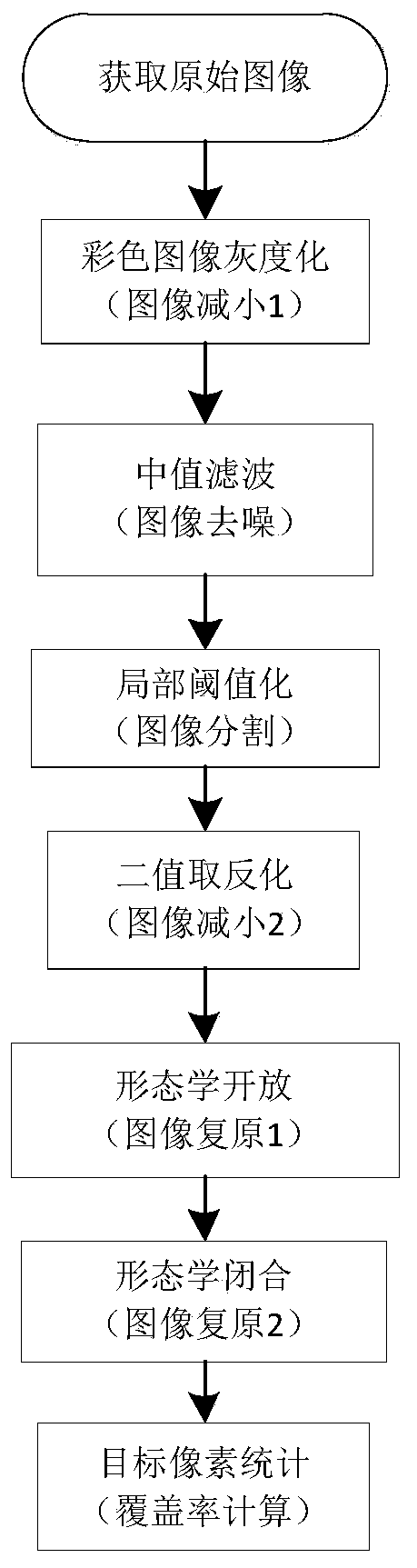

[0036] A kind of digital shot peening coverage measuring method based on computer vision technology of the present invention comprises the following steps:

[0037] Step 1: Use a microscope with a magnification range of 50-200 times and the image acquisition software amcap to obtain the initial image;

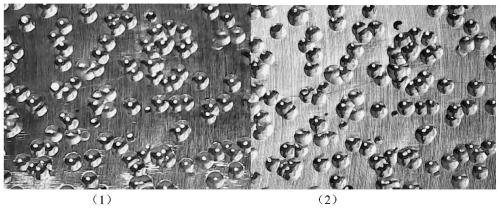

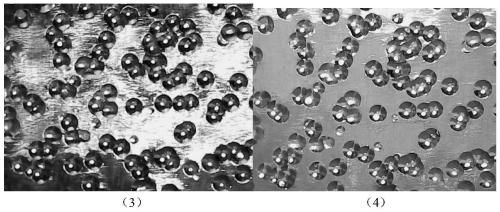

[0038] With the help of a microscopic magnifying glass with a magnification of 50-200 times, and the supporting image display and acquisition software amcap installed on the computer, select a representative area on the surface of the shot peened sheet to take pictures and save them as 480*640 pixels Color png format image. The principle of shooting is: if the coverage rate of the shot blasting sheet is low, such as below 30%, or it is difficult to select a representative area in a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com