A method for manufacturing a large-section high-resolution flexible optical fiber image transmission bundle

An optical fiber image beam, high-resolution technology, used in manufacturing tools, beam optical fibers, glass manufacturing equipment, etc. It can improve the efficiency and uniformity of dissolution, improve the resolution of image transmission, and not easy to break the wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] All raw materials used in the examples are commercially available;

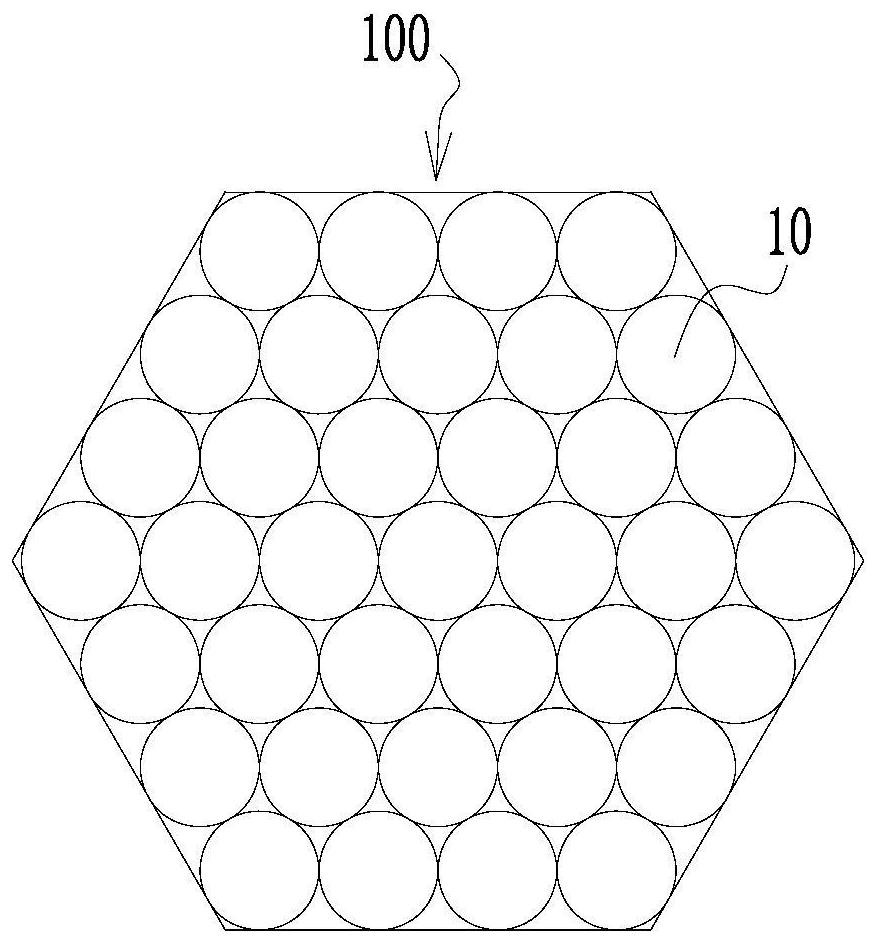

[0036] The cross-sectional size means: when the cross-section is circular, the cross-sectional size refers to the diameter of the circular cross-section; when the cross-section is a regular polygon, the cross-sectional size refers to the distance between two opposite sides.

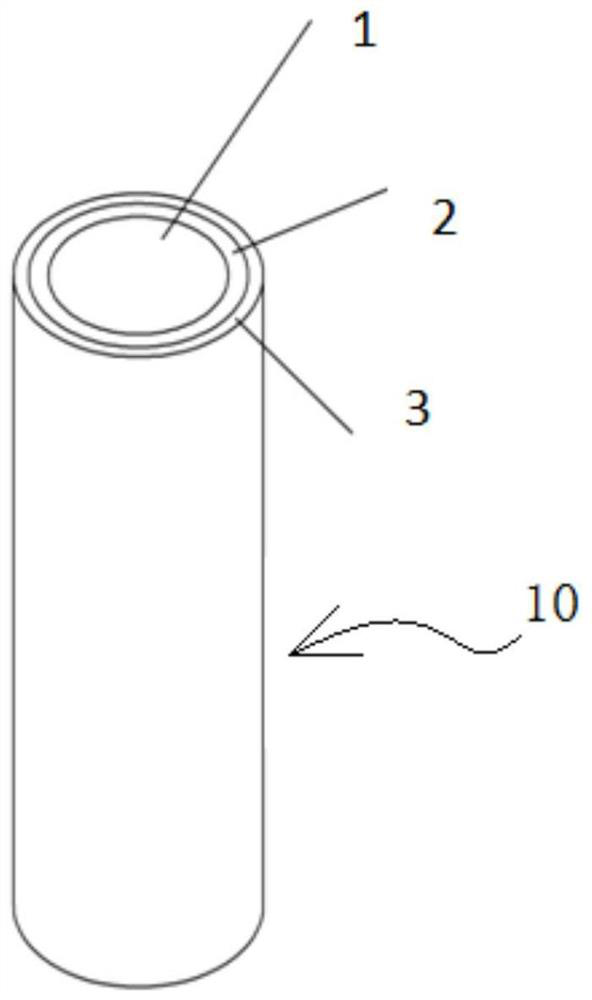

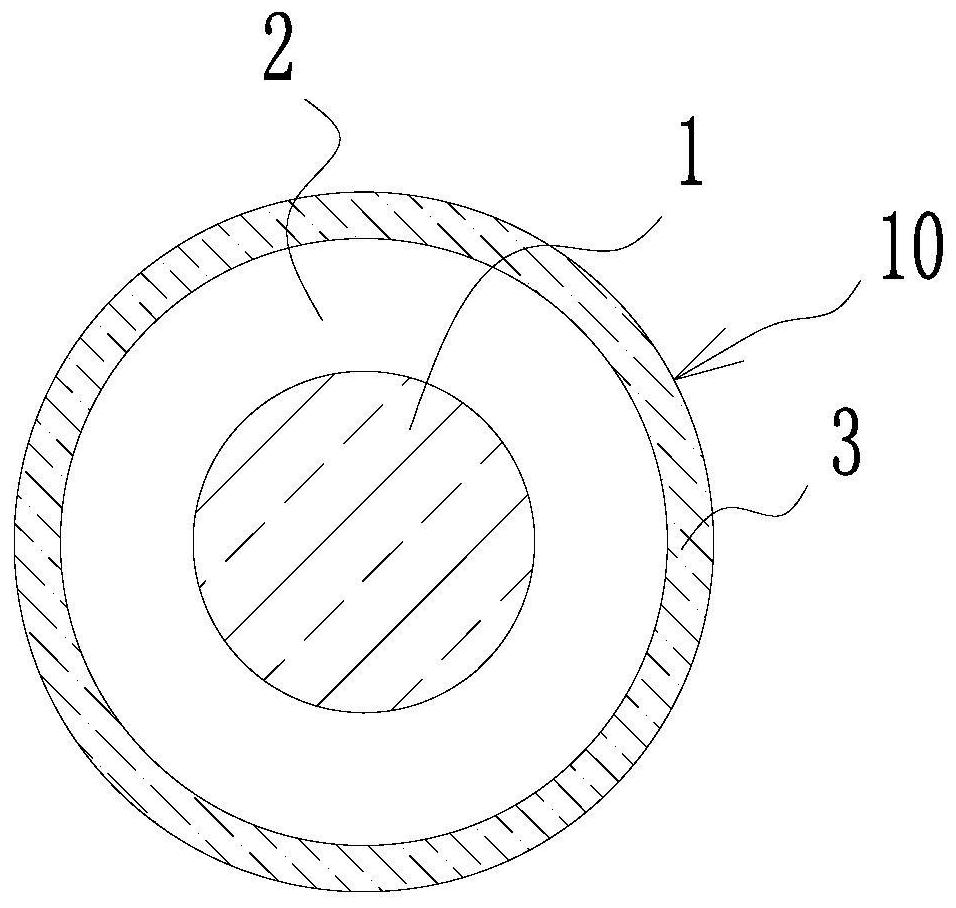

[0037] refer to Figure 1 ~ Figure 4 , the present embodiment provides a method for manufacturing a large-section high-resolution flexible optical fiber image transmission bundle, comprising the following steps:

[0038] S1. Wire drawing: add the shaft core glass rod, skin glass rod and acid-soluble layer glass rod into a three sets of crucibles and heat and melt at the same time. The three sets of crucibles are placed in an electric furnace, and the furnace temperature is controlled at 1100-1200 ° C. The temperature is 800-1000°C, and three layers of coaxial optical fiber monofilaments 10 are drawn at the mouths of three sets of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com