Railway goods inspection intelligent detection device and detection implementation method thereof

An intelligent detection, railway technology, applied in measurement devices, radio wave measurement systems, radio wave reflection/re-radiation, etc. problems, to reduce the influence of external factors, reduce labor intensity, and ensure the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

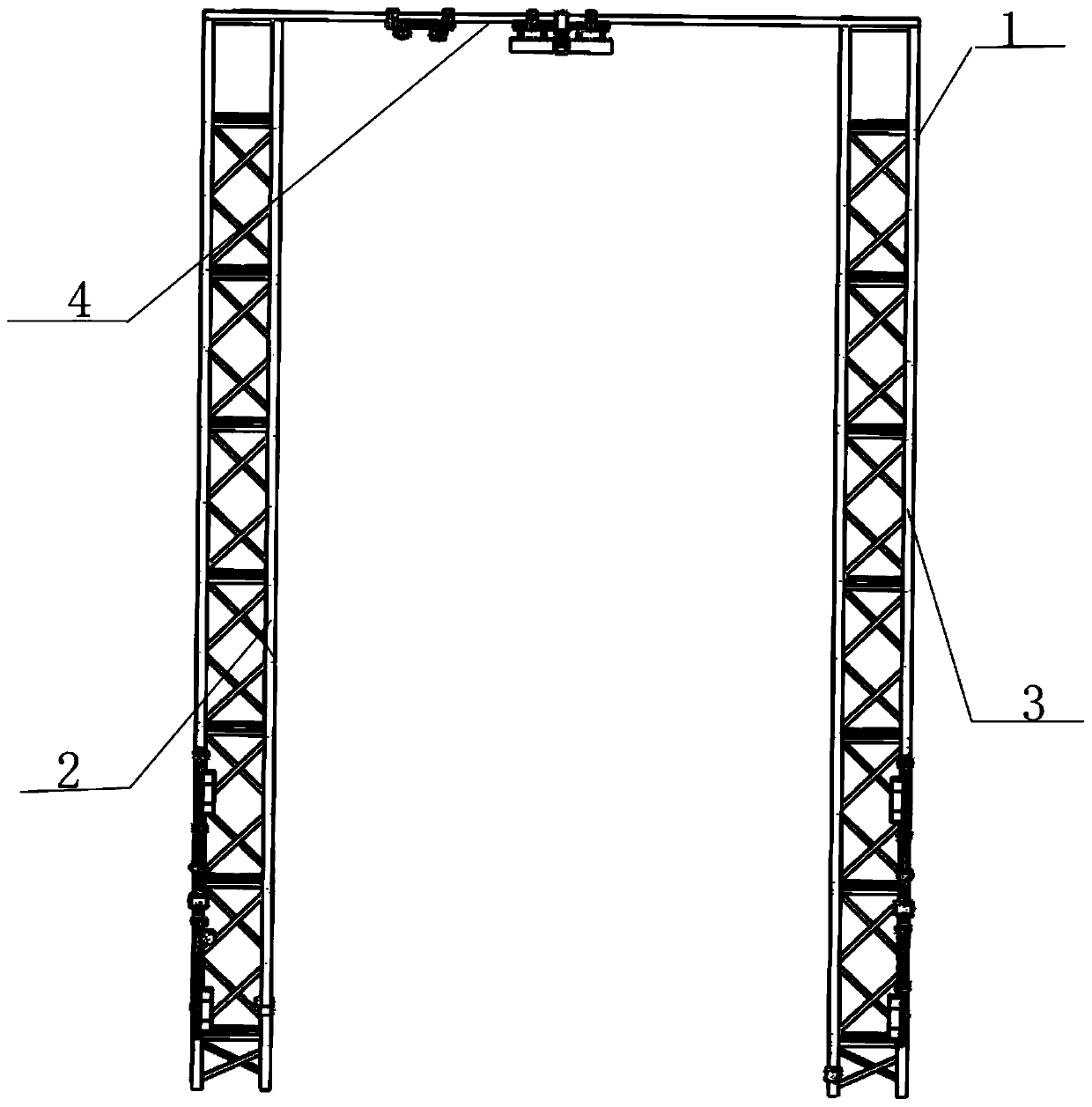

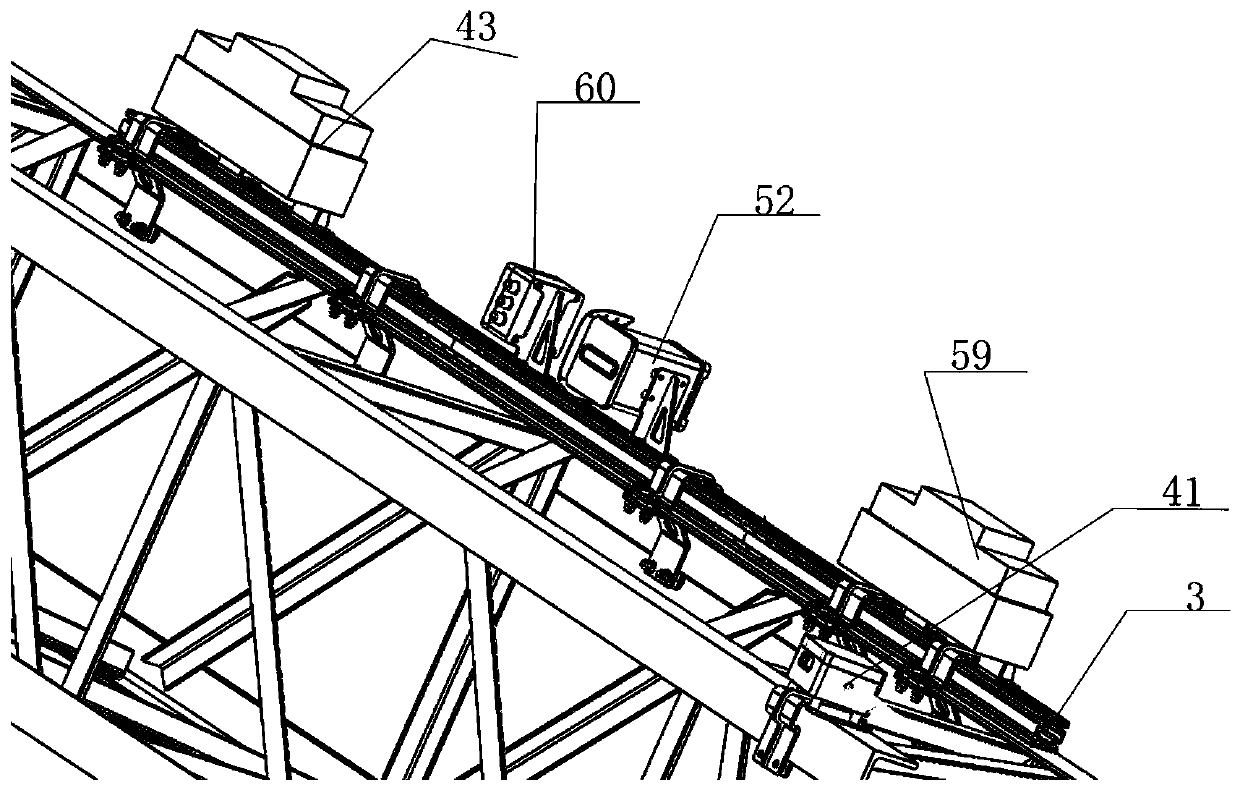

[0049] An intelligent detection device for railway cargo inspection, comprising a portal frame fixed on the ground and through which a freight train passes, a first image acquisition unit fixed on the top of the portal frame for taking images of the top of the freight train, installed on the door The second image acquisition unit is installed on the right side of the portal frame and faces the freight train, and is used to capture the image on the right side of the freight train. Three image acquisition units, fixed on the top of the portal frame, infrared imaging camera for temperature detection of freight trains, fixed on the top of the portal frame, laser radar for detecting the height and width of freight trains, installed on the portal frame One side, the speed measuring radar unit for detecting the running speed of the freight train is installed on both sides of the portal frame 1, and the vehicle cutting sensor for detecting the sectioning of the freight train and output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com