Method for deflating hydraulic acutating apparatus

A hydraulic actuation and actuator technology, which is applied in the direction of fluid pressure actuation device, transmission device control, fluid pressure actuation system components, etc., can solve problems such as foaming and the danger of air entering the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

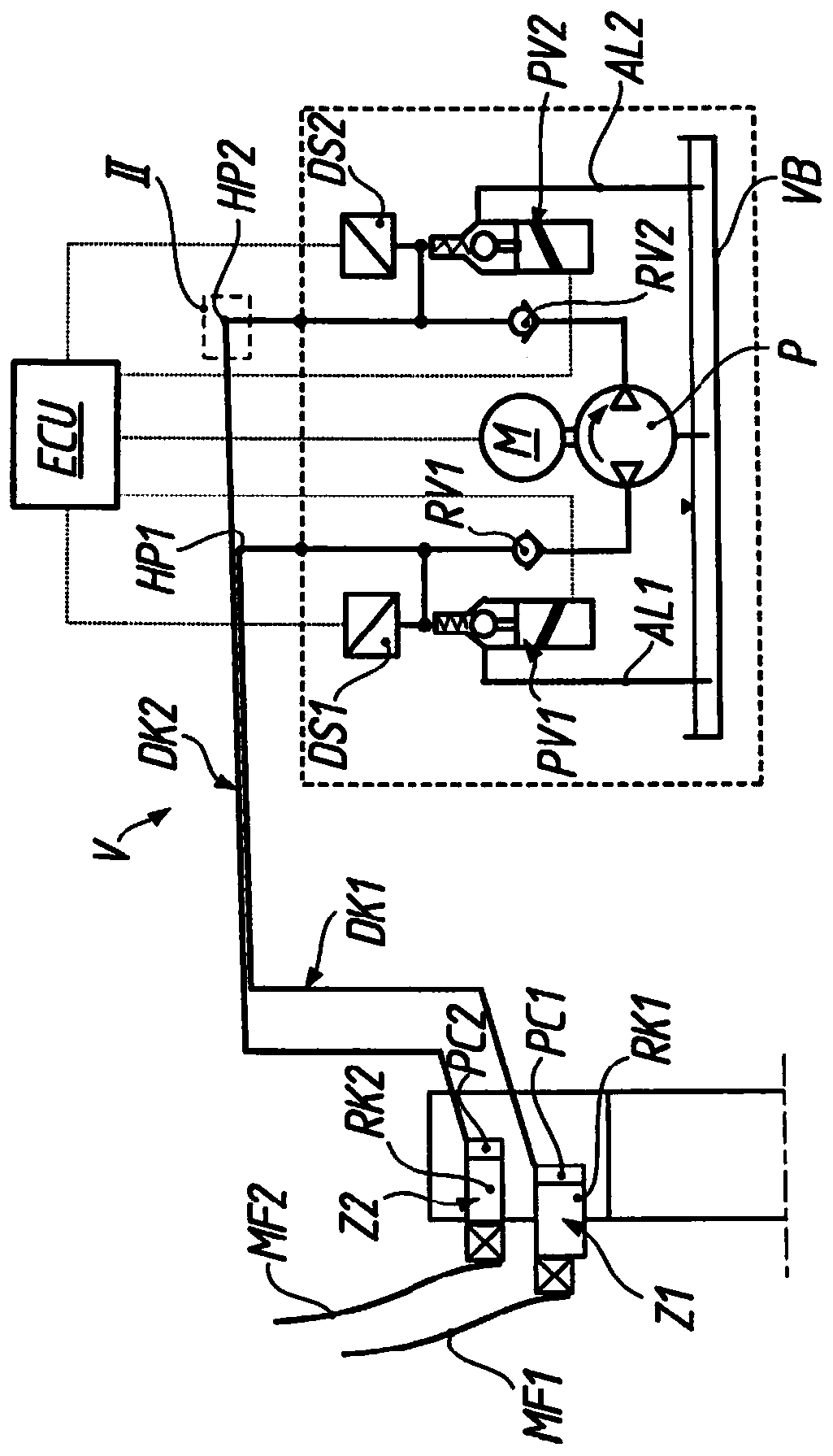

[0033] figure 1 A device V is shown for the hydraulic actuation of two friction clutches (not shown in detail), as is known in principle from the applicant's publication EP2532914A1. The device V comprises a pressure generator (in this case in the form of a dual-circuit hydraulic pump P) with an electric pump drive M, two pressure circuits DK1, DK2 hydraulically connected to the hydraulic pump P and for hydraulic fluid The reservoir VB, hydraulic fluid can be delivered from the reservoir VB through the hydraulic pump P in the pressure circuit DK1, DK2. Starting from the hydraulic pump P, each pressure circuit DK1, DK2 has a non-return valve RV1, RV2 which closes in the direction of the hydraulic pump P and an electromagnetically actuatable proportional throttle valve PV1, PV2 as a pressure regulator, by means of which The valves, the respective pressure circuits DK1 , DK2 , can be released in a defined manner towards the accumulator VB via the outlet lines AL1 , AL2 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com