Air-guide-type reinforcement-type wind turbine blade

A reinforced blade technology, which is applied in the field of wind-guided reinforced windmill blades, can solve the problems of small thrust, easy damage, scattered ejection direction, etc., and achieve the effect of convenient installation, simple process and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

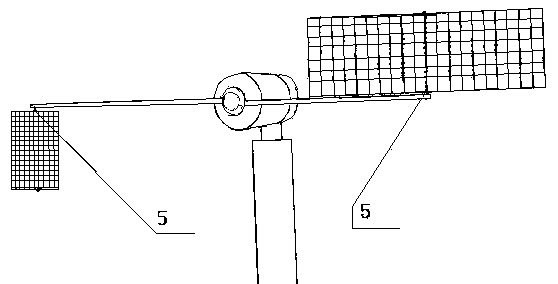

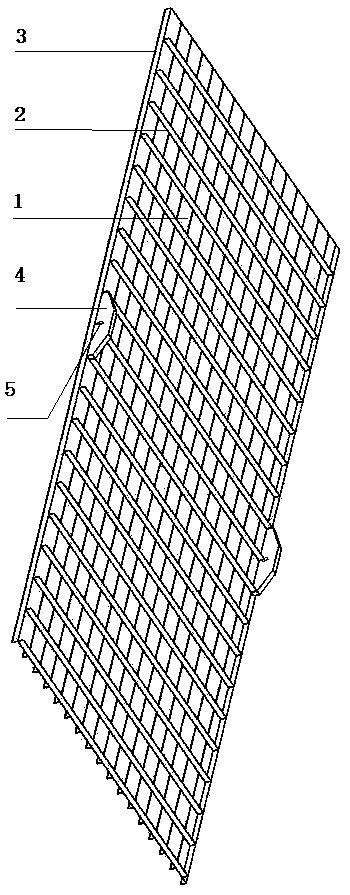

[0007] Specific embodiments: The overall structure and working principle of the present invention will be described in detail in conjunction with the accompanying drawings.

[0008] Overall structure of the present invention: as attached figure 1 As shown, the described wind-guiding reinforced windmill blade: it consists of the main panel of the blade (1), a plurality of ribs (2) arranged on the leeward side of the main panel of the blade, and the ribs (2) arranged on the windward side of the main panel of the blade. It consists of a plurality of wind guiding beams (3), a blade installation nose bridge (4) arranged on the leeward side of the blade main panel, and a blade installation hole (5) arranged on the blade installation nose bridge. The wind-guiding reinforced windmill blade is characterized in that a plurality of reinforcing ribs (2) arranged on the leeward side of the main panel of the blade form a plurality of transverse air-guiding grooves with each other. The wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com