Stepless windmill capable of speeding up automatically

A stepless, windmill technology, applied in wind engines, wind turbine components, mechanical equipment, etc., can solve problems such as low rated speed, broken blades, and high noise, and achieve the effects of prolonging life, safe operation, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

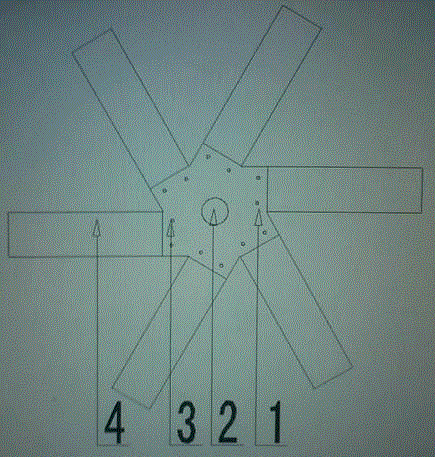

[0008] The overall structure and working principle of the present invention will be described in detail in conjunction with the accompanying drawings.

[0009] Overall structure of the present invention : as attached figure 1 As shown, the self-increasing stepless windmill: it mainly consists of a polygonal hub (1), a shaft mounting hole (2) set in the center of the polygonal hub, a blade mounting hole (3) set on the edge of the polygonal hub and a setting It consists of flexible blades (4) on the edge of the polygonal hub. The self-increasing stepless windmill is characterized in that the flexible blades (4) arranged on the edge of the polygonal hub are composed of a plurality of rectangular flexible flat plates; the self-increasing stepless windmill is characterized in that it is arranged on the polygonal One side length line of each rectangular flexible flat plate of the flexible blade (4) on the edge of the hub coincides with the radius extension line of the polygonal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com