All-thin-film silicon semiconductor double-electrode bias-voltage-free photoelectrocatalysis full-water-decomposition hydrogen production system and application thereof

A photoelectric catalysis and thin-film silicon technology, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., to achieve the effect of slowing down the speed of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

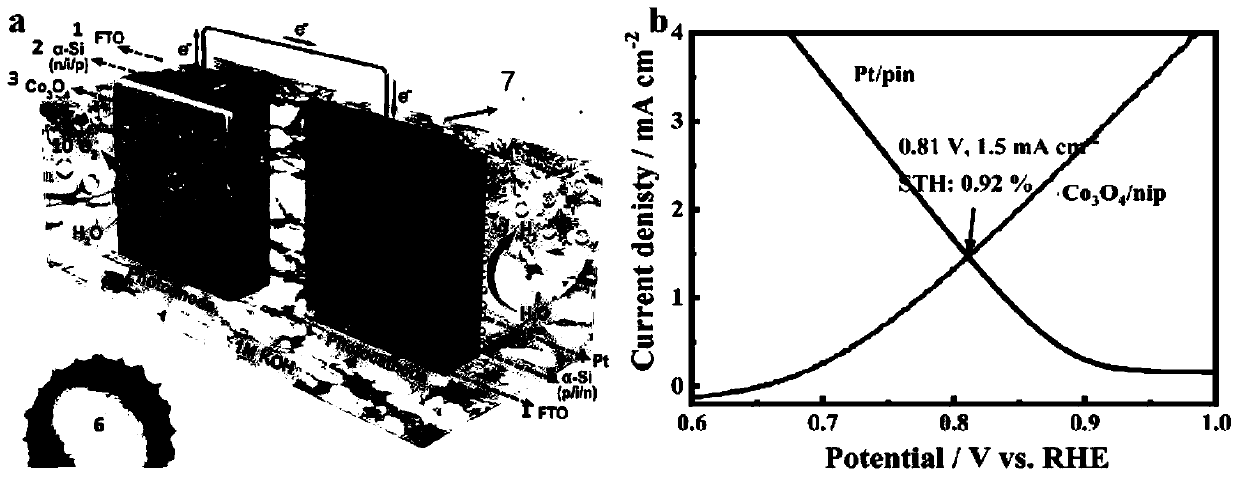

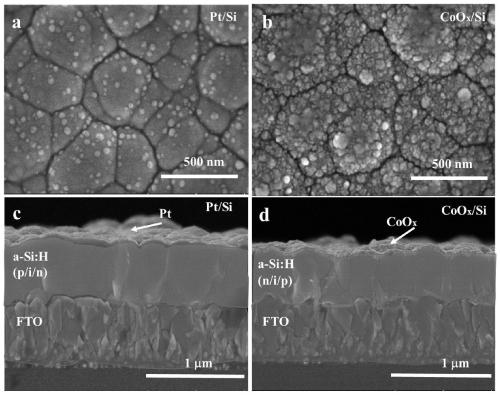

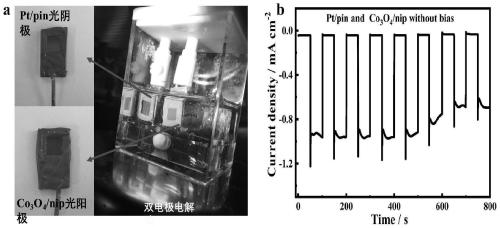

[0026] Such as figure 1 A full-thin-film silicon semiconductor double-electrode unbiased photocatalytic hydrogen production system is shown, which includes Co 3 o 4 / nip photoanode, Pt / pin photocathode, electrolyte, light source 6, electrolytic cell 7, the structure of the photoanode is FTO substrate layer 1, single-section silicon film 2 of n / i / p structure, Co 3 o 4 Oxide film 3, the structure of the photocathode is FTO substrate layer 1, single-section silicon film 5 with p / i / n structure, hydrogen-producing metal Pt nanoparticle film 4, and the electrolyte is 1M KOH solution ; said Co 3 o 4 The preparation method of / nip photoanode is as follows: FTO (transparent conductive glass) substrate 1 is washed with acetone, ethanol, and water for 30 minutes each, then dried, and placed in a very high frequency plasma vapor deposition equipment (PEVCVD) to deposit and deposit n-type sequentially. Silicon thin film, intrinsic silicon thin film and p-type silicon thin film, obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com