Carpet for automobile and manufacturing method thereof

A manufacturing method and carpet technology, applied in chemical instruments and methods, vehicle parts, special positions of vehicles, etc., can solve the problems of easy adhesion of dust, poor wear resistance, easy water absorption, etc., and achieve improved appearance and good wear resistance. , Improve the effect of sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

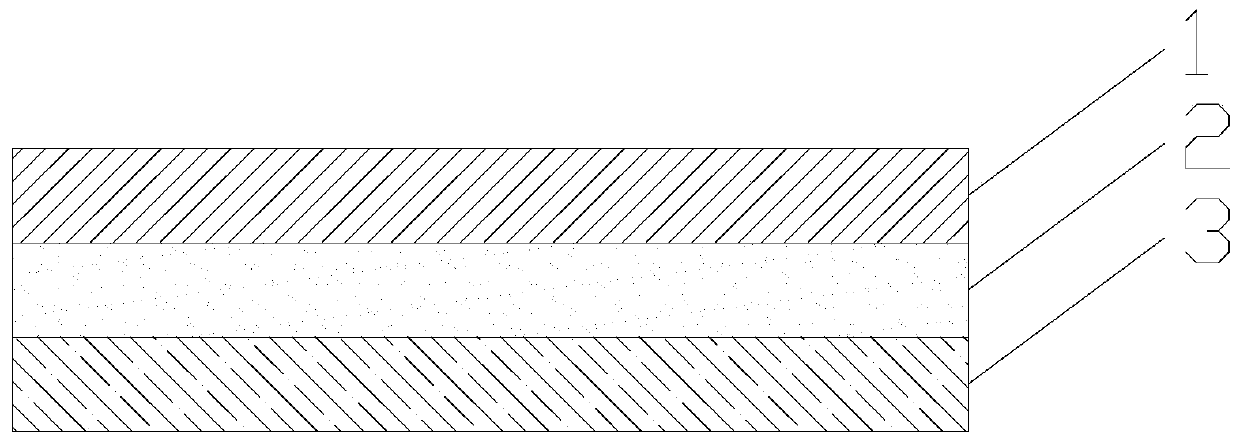

[0035] A kind of carpet for automobiles is a layered structure of three layers, such as figure 1 As shown, the automobile carpet comprises polyurethane soft sound-insulating layer 3, hot-melt adhesive layer 2 and surface protection layer 1 arranged successively from bottom to top; the material of surface protection layer 1 is thermoplastic polyolefin (TPO), and its grammage is 500g / m 2 , with a thickness of 1mm; the material of the hot melt adhesive layer 2 is EPDM, and its weight is 3500g / m 2 , the thickness is 0.5mm; the weight of polyurethane soft sound insulation layer (PUR) 3 is 50g / m 2 , the thickness is 10mm. The surface protection layer 1 is provided with an anti-skid texture.

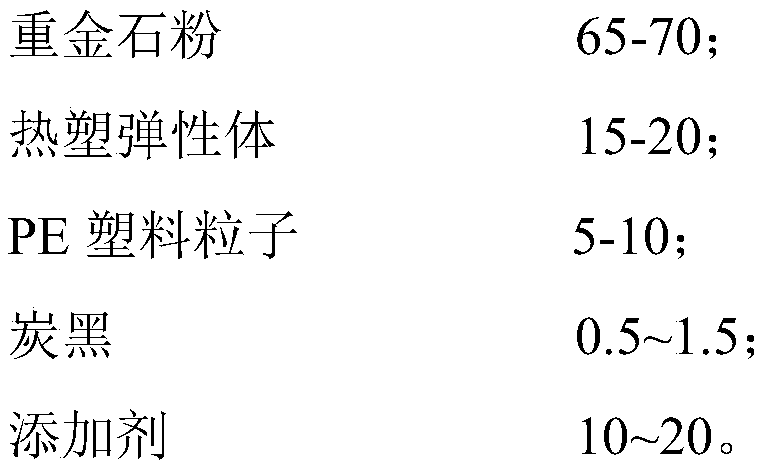

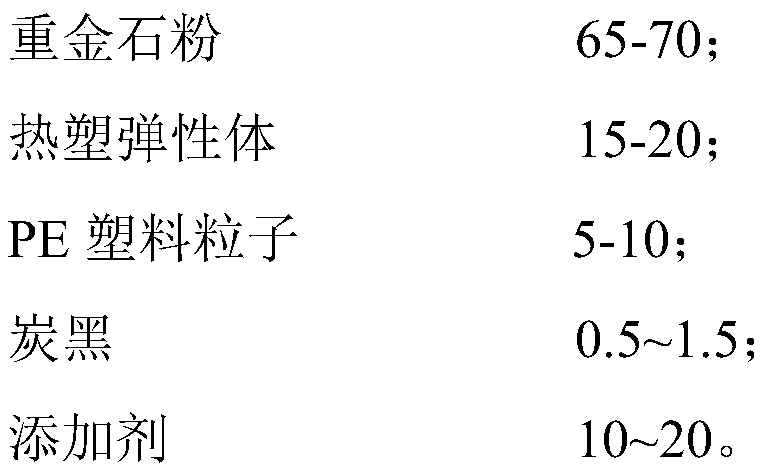

[0036] Among them, EPDM includes the following raw material components:

[0037] 70 parts by weight of heavy gold stone powder;

[0038] 20 parts by weight of thermoplastic elastomer;

[0039] 10 parts by weight of PE plastic particles;

[0040] 1 part by weight of carbon black;

[0041...

Embodiment 2

[0056] A kind of carpet for automobiles is a layered structure of three layers, such as figure 1 As shown, the automobile carpet comprises polyurethane soft sound-insulating layer 3, hot-melt adhesive layer 2 and surface protection layer 1 arranged successively from bottom to top; the material of surface protection layer 1 is thermoplastic polyolefin (TPO), and its grammage is 450g / m 2 , with a thickness of 1.5mm; the material of the hot melt adhesive layer 2 is EPDM, and its weight is 2880g / m 2 , the thickness is 1mm; the weight of polyurethane soft sound insulation layer (PUR) 3 is 80g / m 2 , the thickness is 100mm. The surface protection layer 1 is provided with an anti-skid texture.

[0057] Among them, EPDM includes the following raw material components:

[0058] 70 parts by weight of heavy gold stone powder;

[0059] 20 parts by weight of thermoplastic elastomer;

[0060] 10 parts by weight of PE plastic particles;

[0061] 1 part by weight of carbon black;

[006...

Embodiment 3

[0070] A kind of carpet for automobiles is a layered structure of three layers, such as figure 1 As shown, the automobile carpet comprises polyurethane soft sound-insulating layer 3, hot-melt adhesive layer 2 and surface protection layer 1 arranged successively from bottom to top; the material of surface protection layer 1 is thermoplastic polyolefin (TPO), and its grammage is 550g / m 2 , with a thickness of 1mm; the material of the hot melt adhesive layer 2 is ethylene-vinyl acetate copolymer (EVA), and its grammage is 3520g / m 2 , the thickness is 0.5mm; the weight of polyurethane soft sound insulation layer (PUR) 3 is 60g / m 2 , the thickness is 100mm. The surface protection layer 1 is provided with an anti-skid texture.

[0071] The manufacture method of above-mentioned automobile carpet, comprises the following steps:

[0072] (1) Prepare the TPO film as the surface protection layer, keep the hot melt adhesive layer of EVA in a softened state, and attach the surface prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com