Bending auxiliary equipment for bamboo fiber board

An auxiliary equipment, bamboo fiber technology, applied in the direction of unloading equipment, sawing equipment, mechanical equipment, etc., can solve the problem that bamboo fiber board cannot be automatically used, cannot be operated by one person, pushed away, etc., to improve equipment practicability, Reduce the operation steps and avoid the effect of sliding left and right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

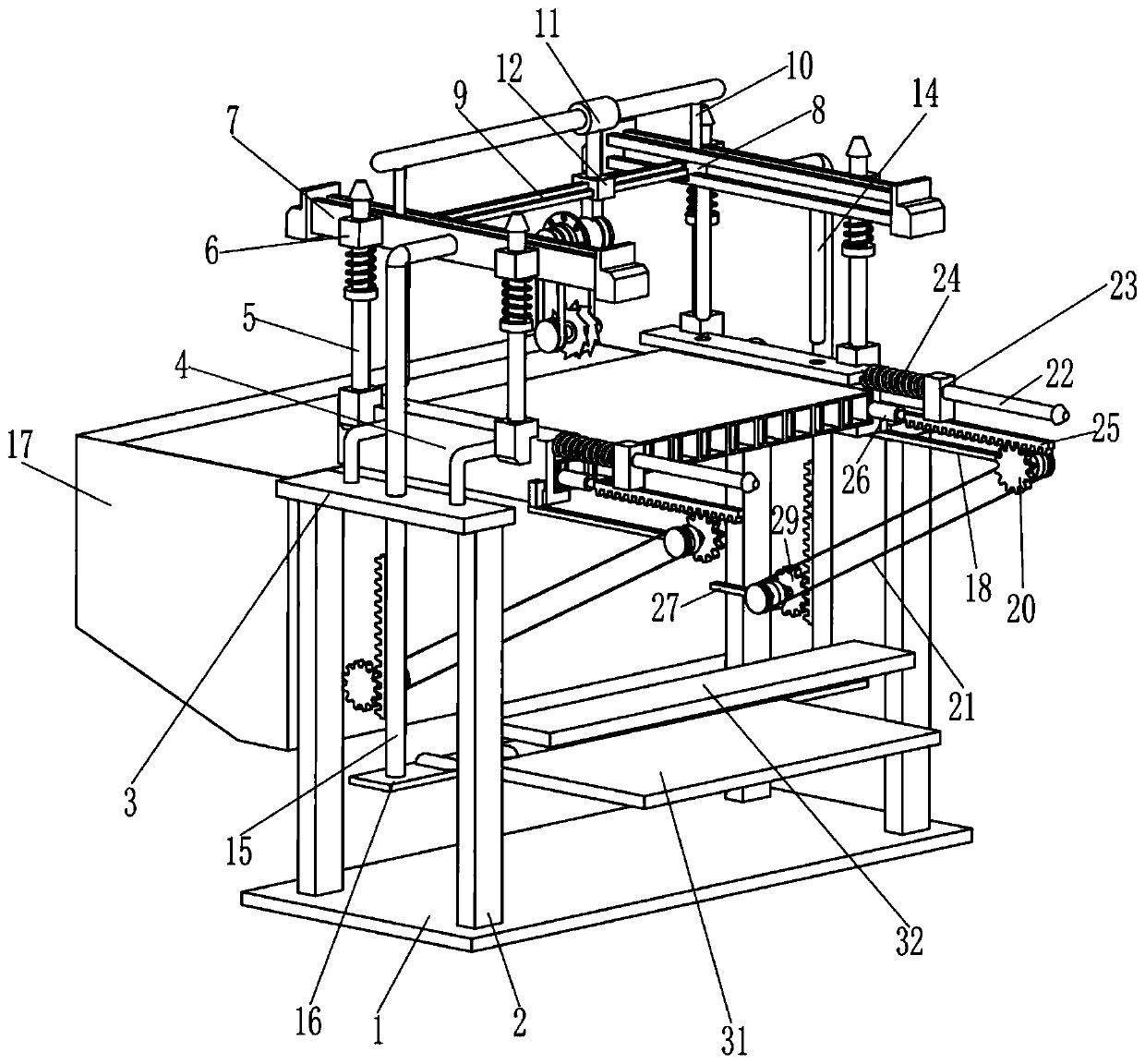

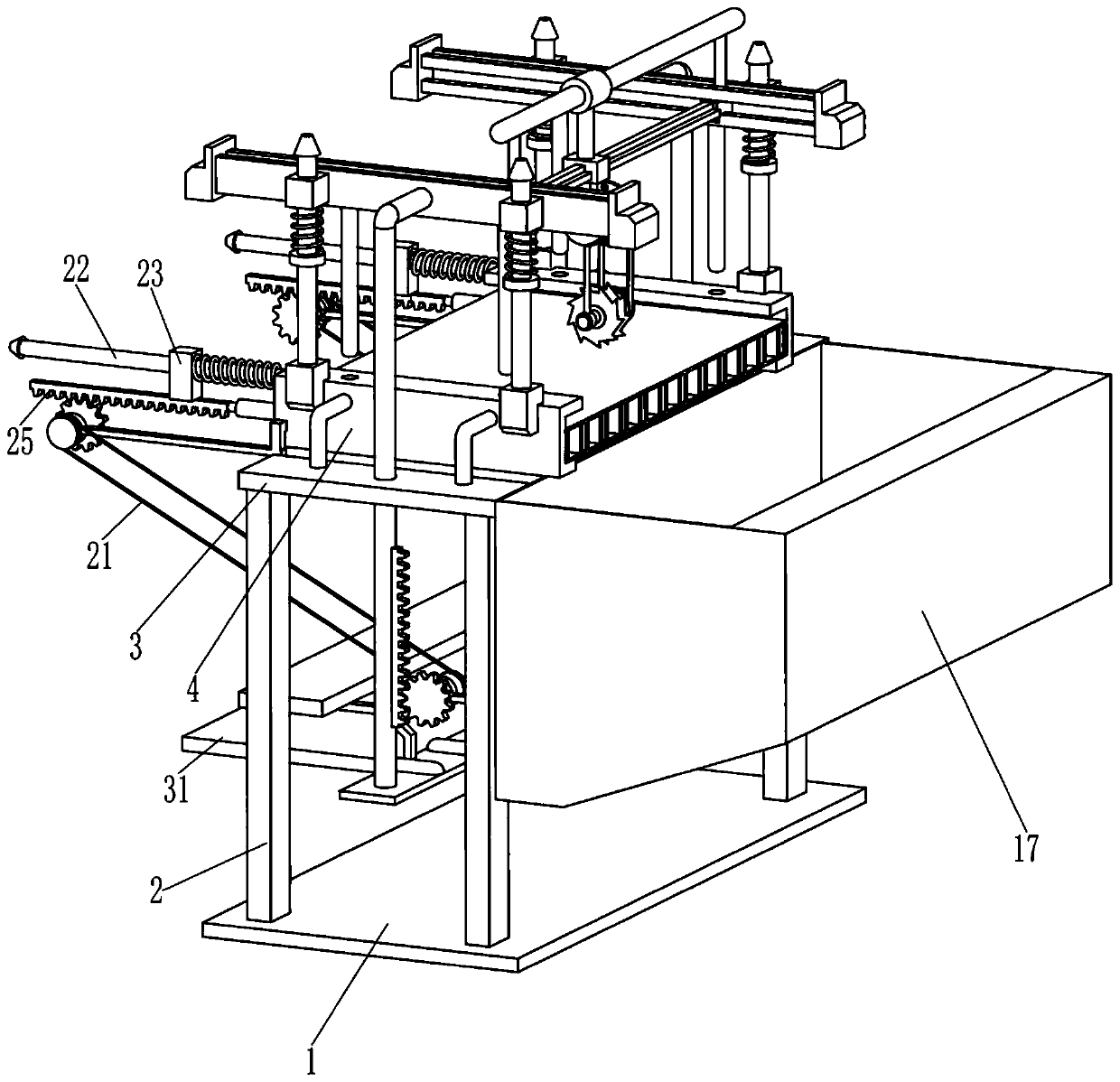

[0021] A kind of bamboo fiber board bending auxiliary equipment, such as Figure 1-4 As shown, it includes bottom plate 1, support rod 2, mounting frame 3, guide plate 4, guide rod 5, reset block 6, guide rail 7, guide block 8, slide rail 9, T-shaped frame 10, sliding sleeve 11, slider 12. Driving motor 1301, bearing housing 1302, first rotating shaft 1303, cutter 1304, transmission assembly 1305, rubber pressing rod 14, pull rod 15, pedal 16 and receiving hopper 17, support rods 2 are provided around the top of bottom plate 1, front and rear A mounting frame 3 is provided between the tops of two adjacent support rods 2, a guide plate 4 is provided on the mounting frame 3, and guide rods 5 are provided on both sides of the top of the guide plate 4, and a reset block is slidably connected to the guide rod 5 6. A guide rail 7 is provided on the inner side of the reset block 6 between the two adjacent parts. The guide rail 7 is slidably connected with the guide block 8. There is ...

Embodiment 2

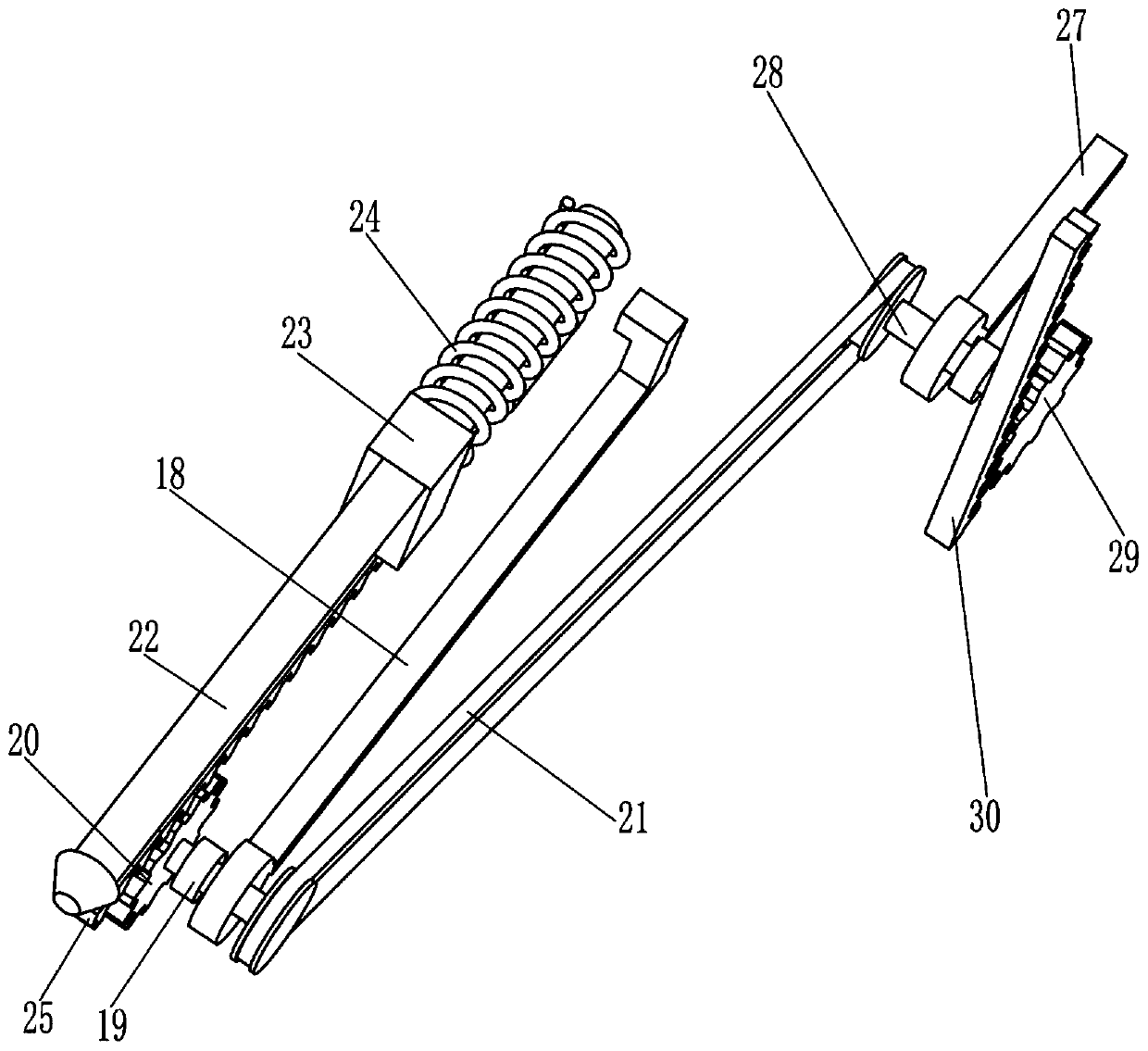

[0024] On the basis of Example 1, such as Figure 1-3 As shown, it also includes a first mounting seat 18, a one-way transmission shaft 19, a first drive gear 20, a drive assembly 21, a sliding rod 22, a guide sleeve 23, a compression spring 24, a first rack 25, a push rod 26, The second mounting base 27, the second rotating shaft 28, the second drive gear 29 and the second rack 30, the mounting frame 3 is provided with a first mounting base 18, and the first mounting base 18 is rotatably connected with a one-way transmission shaft 19 One end of the one-way transmission shaft 19 is provided with a first drive gear 20, the other end of the one-way transmission shaft 19 is connected with a drive assembly 21, one side of the installation frame 3 is provided with a sliding rod 22, and the sliding rod 22 is slidably connected with a guide sleeve 23 A compression spring 24 is connected between the guide sleeve 23 and the installation frame 3, the bottom of the guide sleeve 23 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com