Electrical capacitance tomography sensor and system for high temperature fluidized bed measurement

A technology of electrical capacitance tomography and high-temperature fluidized bed, which is applied in the field of sensors, can solve the problems of difficult design and manufacture, great signal influence, etc., and achieve the effect of meeting the needs of dynamic testing, good insulation effect, and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

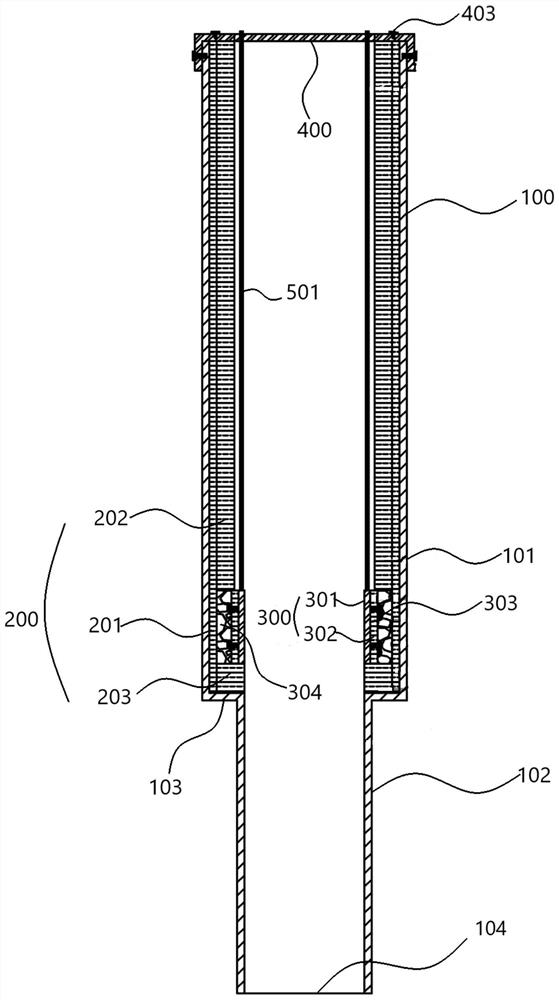

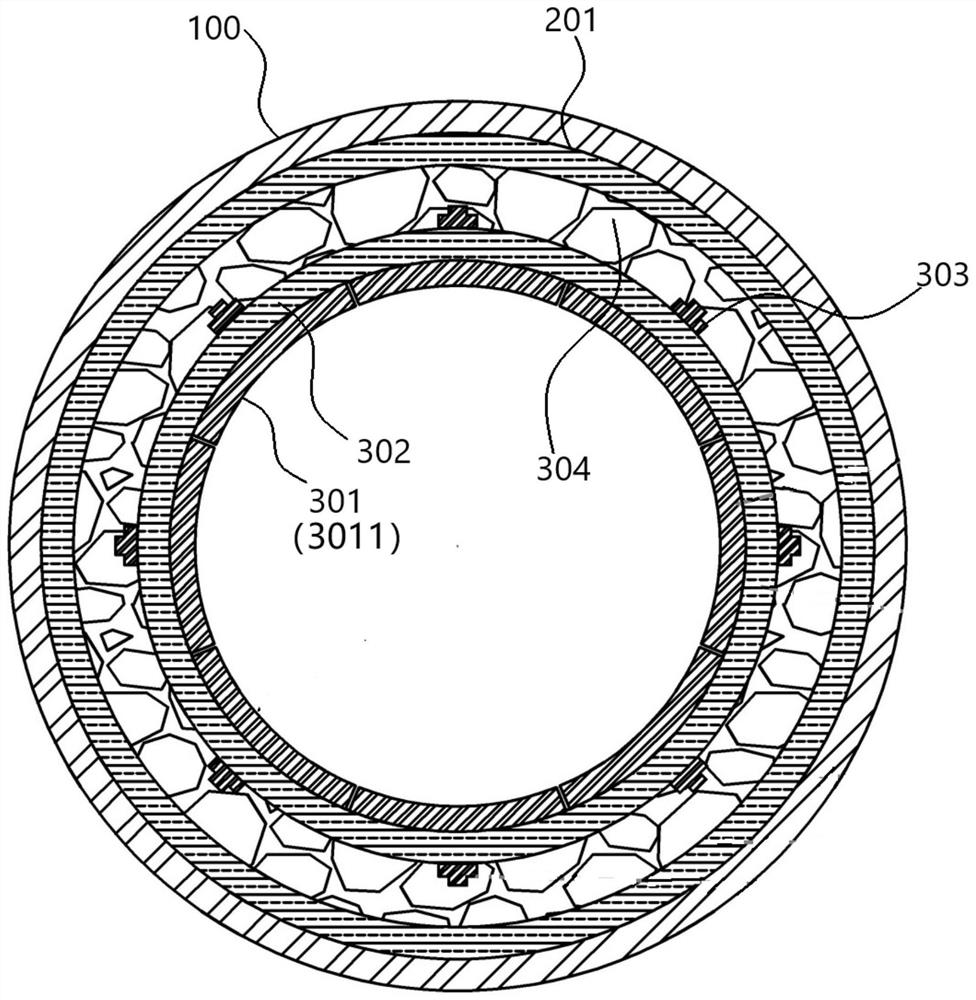

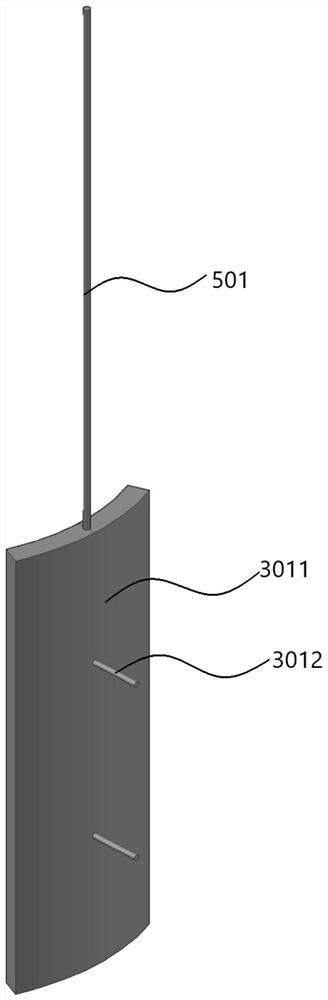

[0055] figure 1 It is a longitudinal sectional view of an electrical capacitance tomography sensor in an embodiment of the present application, figure 2 It is a transverse cross-sectional view of an electrical capacitance tomography sensor in an embodiment of the present application, image 3 It is a schematic structural diagram of a single electrode in an electrical capacitance tomography sensor in an embodiment of the present application, Figure 4 It is a schematic structural diagram of a fixed cap in an electrical capacitance tomography sensor in an embodiment of the present application, combined with Figure 1~4 This embodiment will be specifically described.

[0056] The electrical capacitance tomography sensor provided in this embodiment includes a metal outer tube 100, a first insulating tube 200, and an electrode assembly 300; A high-temperature fluidized bed is formed in the cavity; the first insulating tube 200 is detachably inserted and fixed in the inner cavit...

Embodiment 2

[0077] Figure 5 It is a schematic structural diagram of an electrical capacitance tomography system in an embodiment of the present application, combined with Figure 5 The implementation of this embodiment will be described in detail.

[0078] This embodiment provides a capacitance tomography system, including a plurality of signal transmission lines 500 and any capacitance tomography sensor in the above-mentioned embodiments, and the plurality of signal transmission lines 500 are connected to the array electrode 301 for transmitting the array electrode 301 measures electrode signals.

[0079] Specifically, the number of signal transmission lines 500 is equal to the number of single electrodes in the array electrode 301, for example, when there are 8 single electrodes, there are 8 signal transmission lines 500, and each signal transmission line 500 is connected to a single electrode one by one. corresponding connection.

[0080] Optionally, the signal transmission line 50...

Embodiment 3

[0091] The electrical capacitance tomography sensor provided by the present application will be further introduced below.

[0092] Such as figure 1 and figure 2 As shown, the array electrode 301 includes 8 single electrodes of the same size, and the 8 single electrodes include a tile-shaped measurement part 3011 made of a stainless steel bar through a turning process and a wire cutting process. The outer diameter of the tile-shaped measuring part 3011 is equal to the inner diameter (45mm) of the supporting insulating tube 302, the length of the measuring part 3011 is 50 mm, and the thickness is 2 mm; the outer arc surface of the measuring part 3011 is welded by argon arc welding two long An M2.5 stainless steel screw of about 5 mm is used as the fixing part 3012 and the distance between the two screws is 25 mm. A stainless steel wire with a length of 500 mm and a diameter of 1 mm is welded at the middle of the top of the measurement part 3011 as the cable core of the high-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com