Charging container for combustion, charging method of charging container for combustion and synthesis method of high alpha-phase silicon nitride

A charging container and a charging technology are applied to a charging container for combustion and a charging method thereof, and the synthesis field of high-alpha phase silicon nitride, which can solve the problems of waste, labor and time, and achieve the purpose of recycling powder. The effect of less quantity, reduced picking workload, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a charging container for combustion, including: a charging boat for charging, the charging boat is a hollow structure with an open top, and the charging container for combustion also includes: thermal insulation material, and a hollow structure for the charging boat The inside is filled with breathable thermal insulation material, or the surface of the charging boat is provided with breathable thermal insulation material.

[0036] This embodiment provides a charging method using the above-mentioned charging container for combustion, comprising the following steps:

[0037] 1) Fill the material to be burned in the above-mentioned charging container;

[0038] 2) Select the ignition area in the charging container, dig out the materials to be burned in the ignition area, add an ignition wire in the ignition area, then add the ignition powder that is not filled with the ignition area in the ignition area, and then add the ignition powder in the ignit...

Embodiment 2

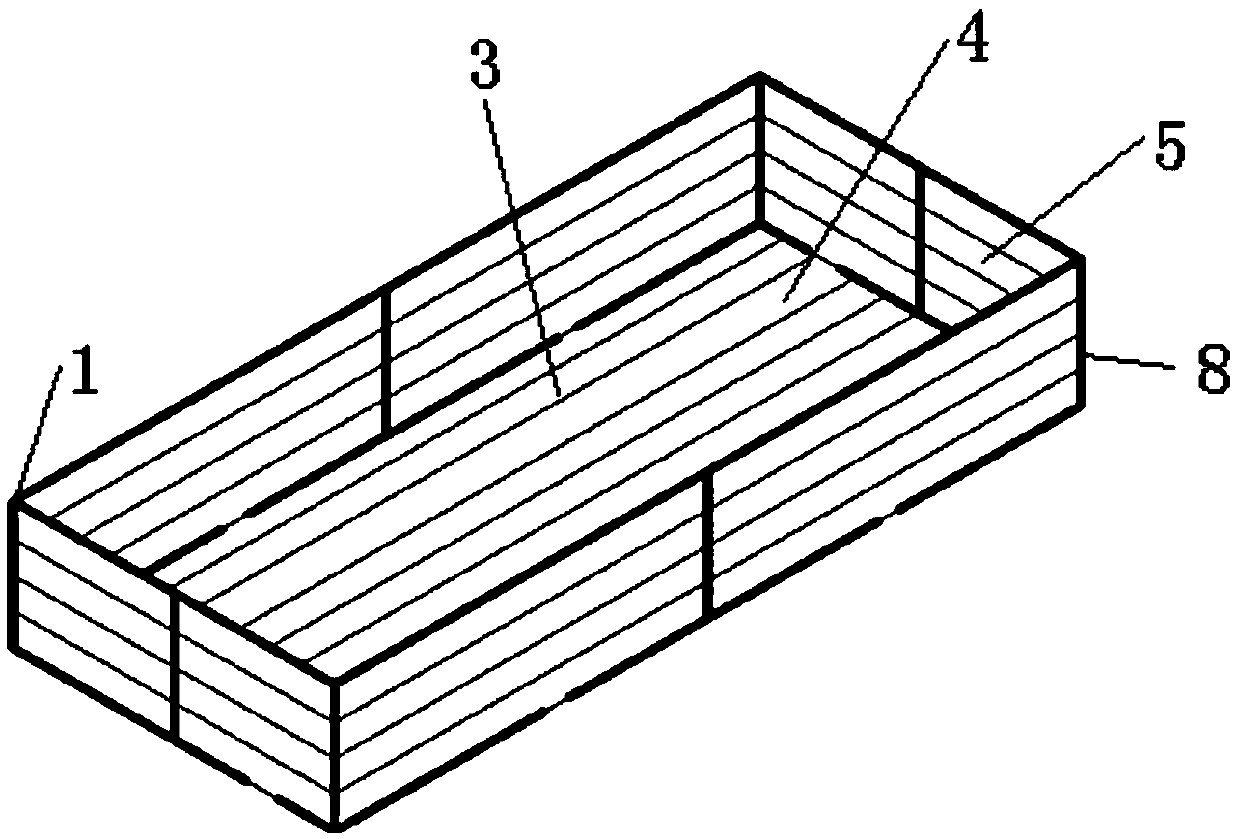

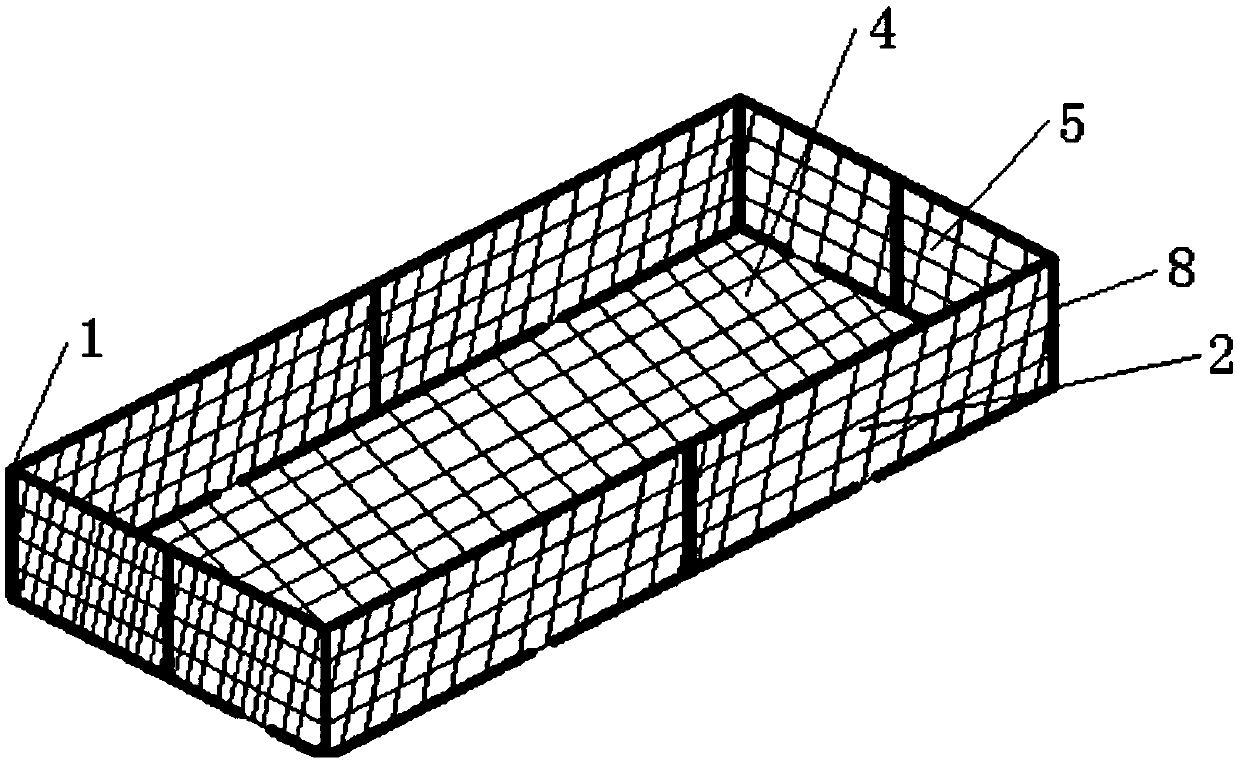

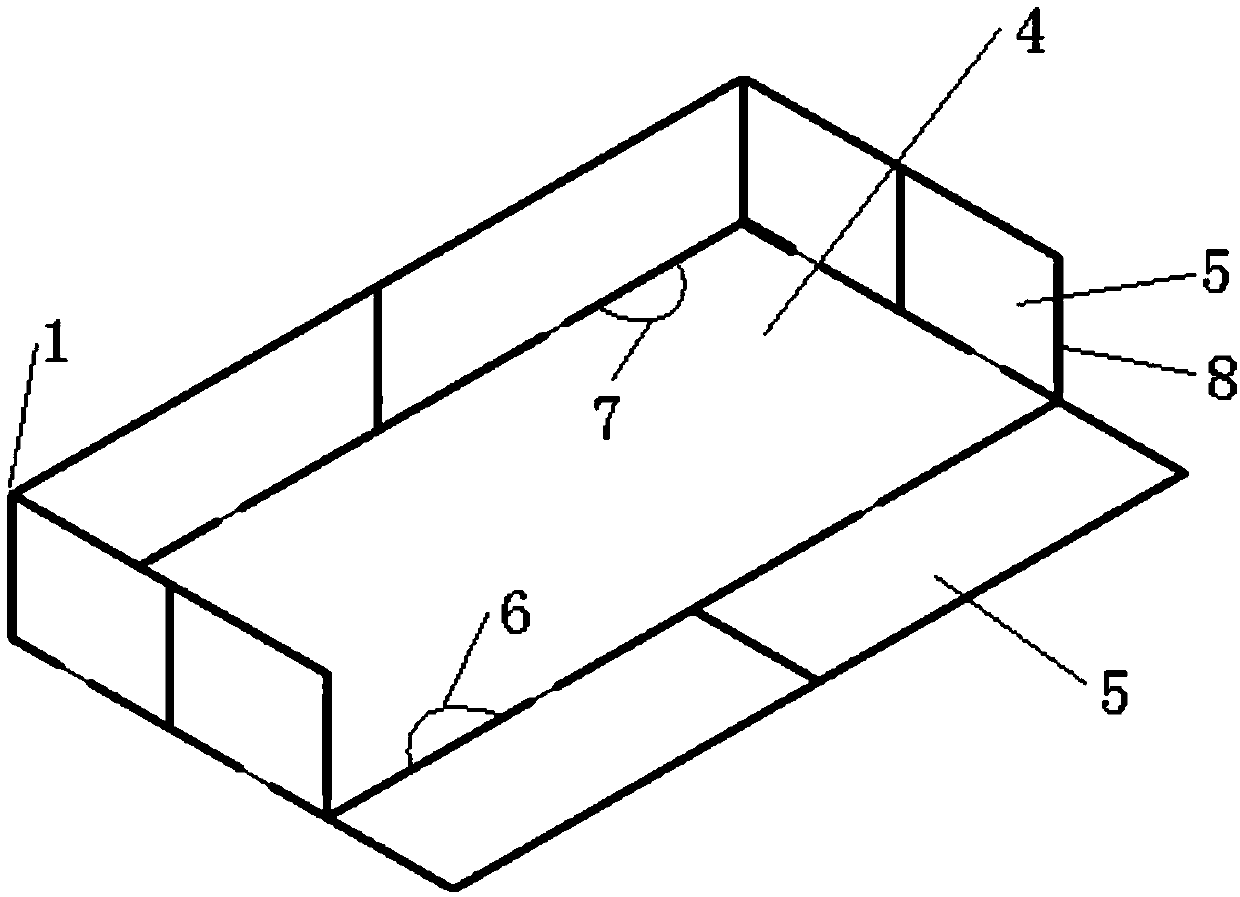

[0044] Such as Figure 1~3 As shown, the present embodiment provides a charging container for combustion, including: a charging boat 1 for charging, the charging boat 1 is a hollow structure with an open top, and the charging container for combustion also includes: an insulating material 2, The hollow structure of the charging boat 1 is filled with a breathable thermal insulation material 2 , or the surface of the charging boat 1 is provided with a breathable thermal insulation material 2 .

[0045] Such as figure 1 As shown, it should be noted that the hollow structure of the charging boat 1 in this embodiment is a hollow structure formed by connecting strip rods 3 arranged parallel to each other through connecting rods 8 .

[0046] It should be noted that, in this embodiment, the gap between two adjacent strip bars 3 parallel to each other is 25mm.

[0047] It should be noted that the porosity of the thermal insulation material 2 in this embodiment is 30-60%.

[0048] Suc...

Embodiment 3

[0067] The present embodiment provides a kind of charging container for combustion, and the difference in embodiment 2 is:

[0068] It should be noted that, in this embodiment, the gap between two adjacent bar-shaped bars parallel to each other is 5 mm.

[0069] It should be noted that the porosity of the thermal insulation material in this embodiment is 30-60%.

[0070] It should be noted that the thermal insulation material in this embodiment is alumina fiber felt.

[0071] It should be noted that the material of the charging boat in this embodiment is 316 stainless steel.

[0072] This embodiment also provides a charging method using the above-mentioned charging container for combustion, which differs from the charging method in Embodiment 2 as follows:

[0073] The composite powder described in step 2) is obtained by mixing the ignition powder dug out from the ignition area with 1 / 3 of its weight silicon powder.

[0074] It should be noted that the ignition powder in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com