Integrated oil pumping device

An integrated, oil-pumping technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, pumps, etc., can solve the problems of occupying transmission space, large flow leakage, and rapid kinetic energy drop, and achieves a reduction in Assembly space, small pressure pulsation, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

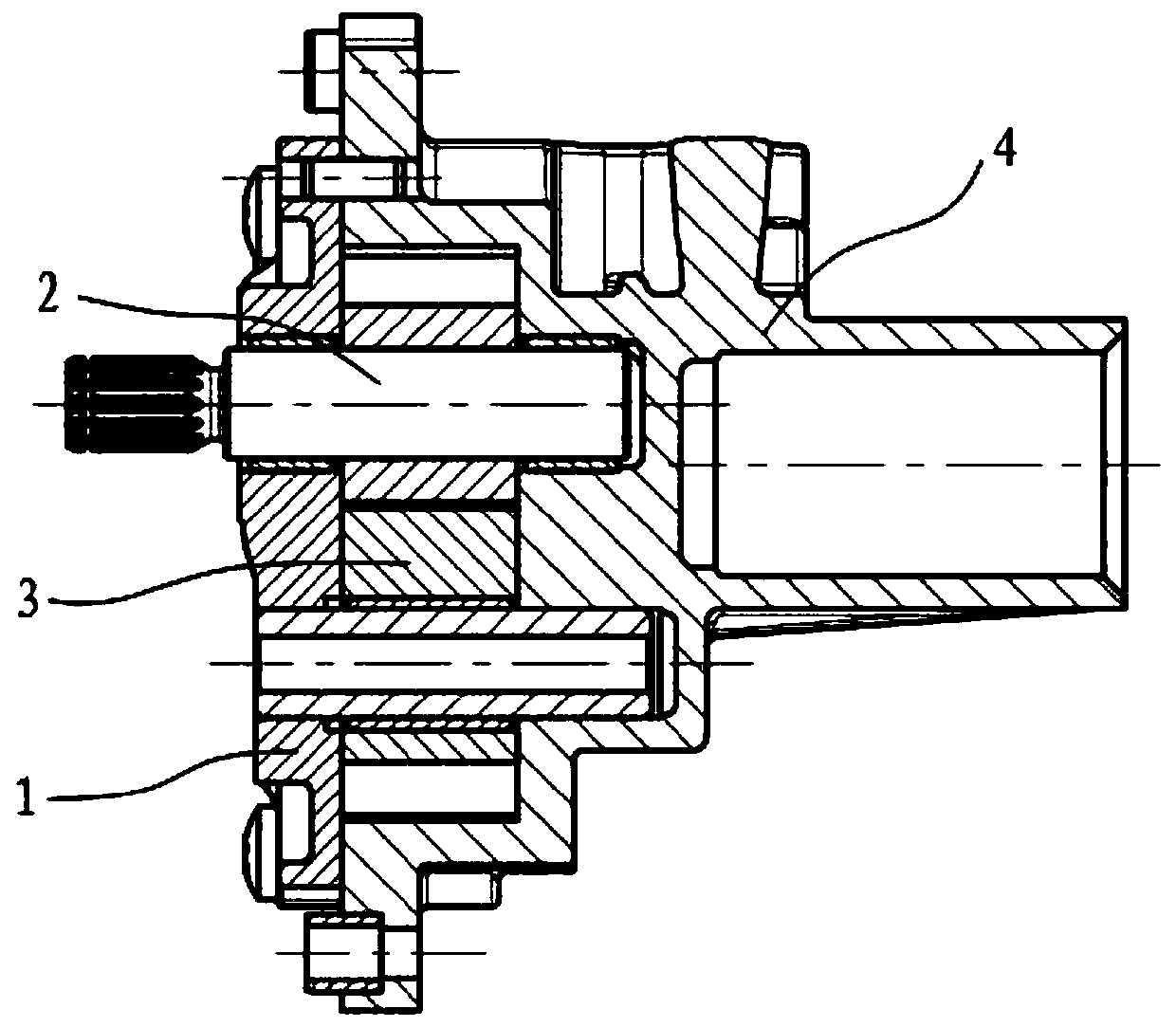

[0046] This embodiment discloses an integrated oil pumping device, see figure 1 , including a pump cover assembly 1 , a drive assembly 2 , a driven assembly 3 and a pump body assembly 4 .

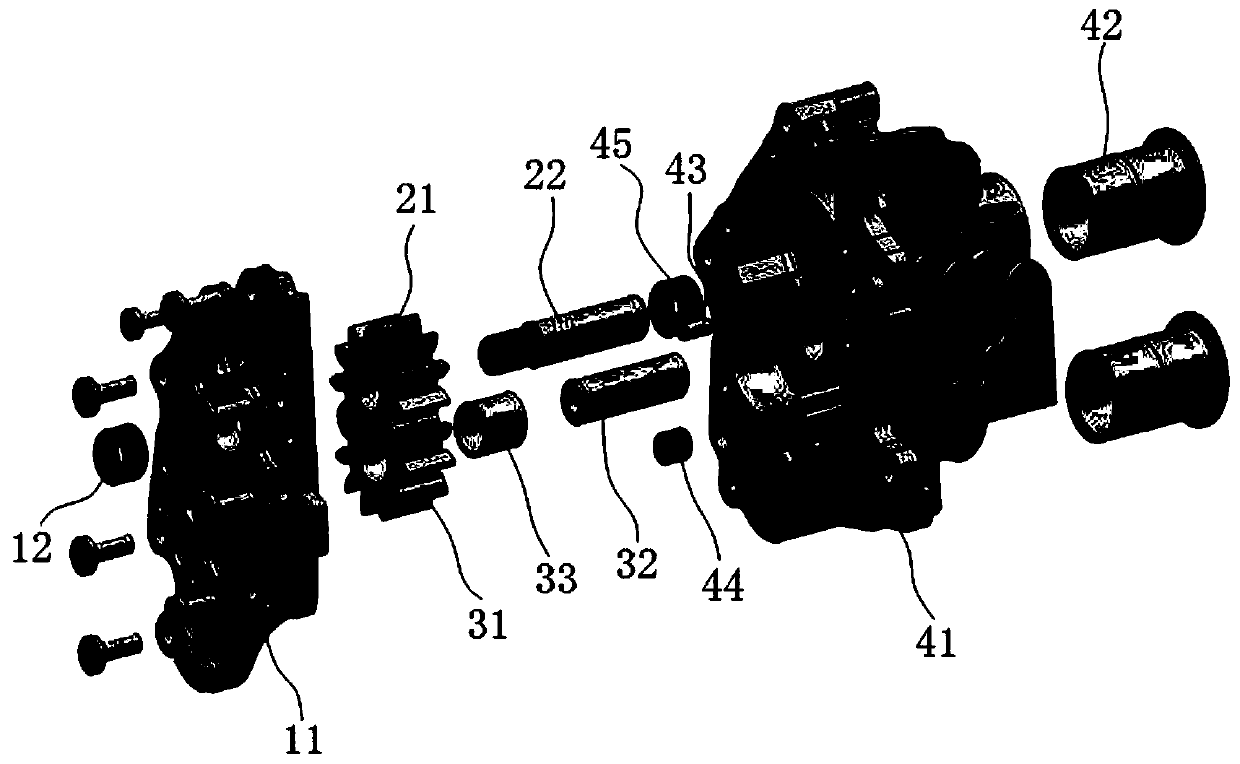

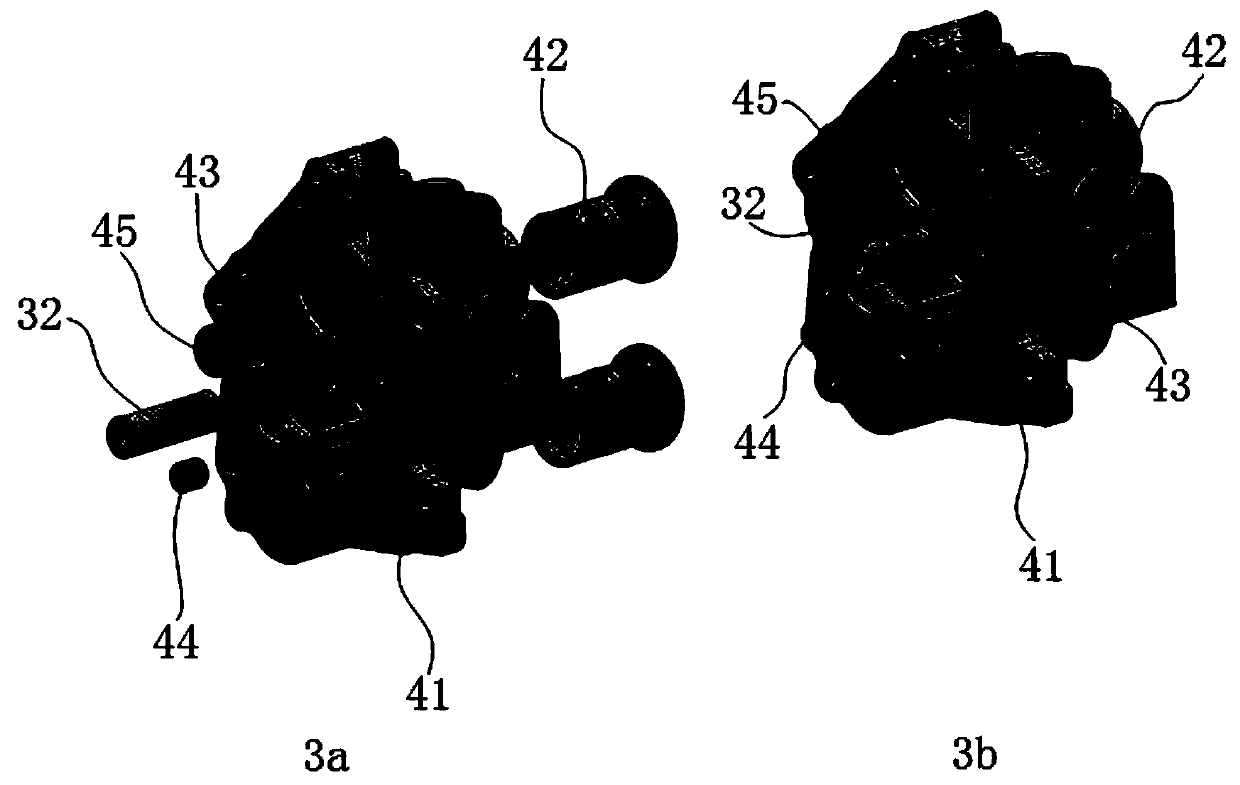

[0047] see Figure 2 to Figure 5 , the main component of the pump body assembly 4 is the pump body 41 .

[0048] A pair of gear cavities are processed in the middle of the pump body 41, and the drive shaft shaft hole I4101 and the driven shaft shaft hole I4102 are respectively processed in the gear cavity. An oil drain groove 41011 is opened at the bottom of the shaft hole I4101 of the drive shaft. The shaft hole I411 of the drive shaft is press-fitted with a pump body bushing 45 through interference fit, and the pump body bushing 45 is a bimetal rolled bush.

[0049]An oil inlet groove I4103 and an oil outlet groove I4104 are respectively provided at the upper and lower ends of the gear chamber. The oil outlet groove I4104 is connected to the shaft hole I4102 of the driven shaft throug...

Embodiment 2

[0066] This embodiment discloses a relatively basic implementation method, an integrated oil pumping device, see figure 1 , including a pump cover assembly 1 , a drive assembly 2 , a driven assembly 3 and a pump body assembly 4 .

[0067] see Figure 2 to Figure 5 , the main component of the pump body assembly 4 is the pump body 41 .

[0068] A pair of gear cavities are processed in the middle of the pump body 41, and the drive shaft shaft hole I4101 and the driven shaft shaft hole I4102 are respectively processed in the gear cavity.

[0069] An oil inlet groove I4103 and an oil outlet groove I4104 are respectively provided at the upper and lower ends of the gear chamber.

[0070] The side wall of the pump body 41 is provided with an oil inlet 4107 connected to the oil inlet groove I4103 and an oil return port 4109. The oil return port 4109 is used to collect the oil return of the transmission hydraulic system. The oil return has a certain pressure and is It communicates wi...

Embodiment 3

[0083] The main structure of this embodiment is the same as that of Embodiment 2. Furthermore, a buffer groove I1107 extends on the side wall of the oil outlet groove II1104 close to the shaft hole II1101 of the drive shaft. A buffer groove II1108 extends on the side wall of the oil outlet groove II1104 close to the shaft hole II1102 of the driven shaft.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com