Method for preventing and treating large-mining-high caving coal dust

A technology of large mining height and coal falling, which is used in earth-moving drilling, slitting machinery, non-rotational vibration suppression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

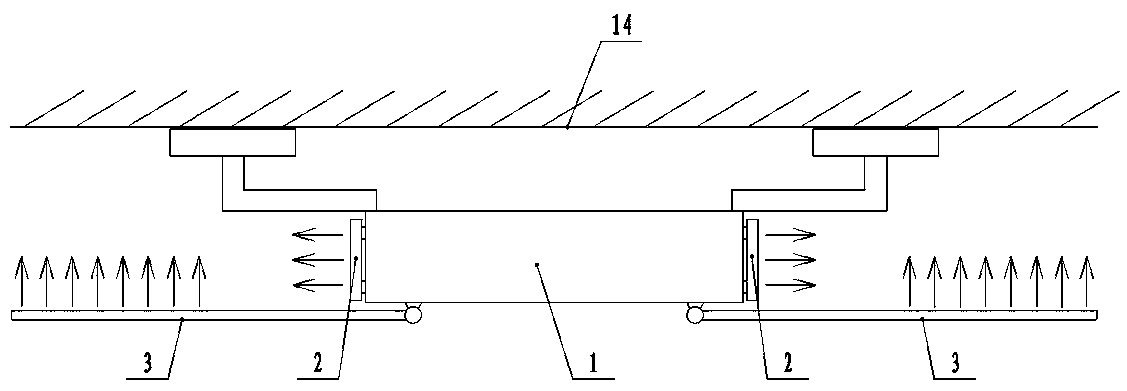

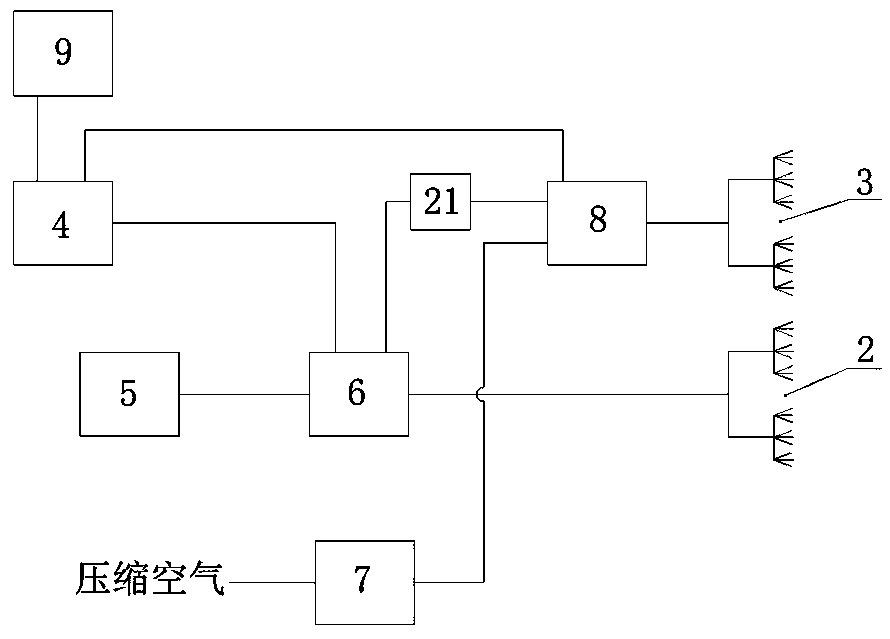

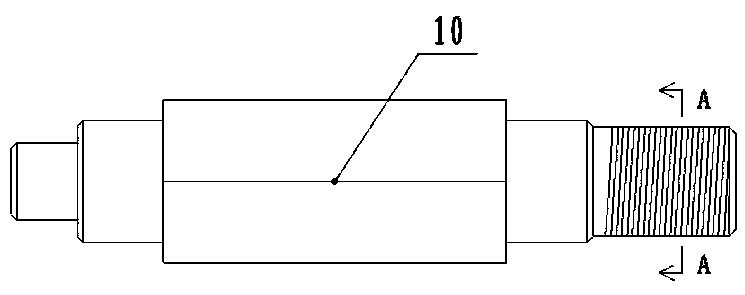

[0024] Such as Figure 1 to Figure 5 As shown, a method for preventing and controlling coal dust falling from large mining heights is based on a shearer 1, on which a spray module 2 and a cantilever spray bar 3 are set, and a PC central controller 4, a water distributor 6, and a pressure reducing valve are equipped. 21. Air-water distributor 8, spray pump 5, air storage tank 7 and dust sensor 9; wherein, spray module 2 is connected to water distributor 6, water distributor 6 is connected to spray pump 5, cantilever spray rod 3 is connected to air-wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com