H-shaped steel beam and h-shaped steel column strong shaft assembled joint and construction method

An H-shaped steel and shaft assembly technology, which is applied in the direction of columns, pillars, pier columns, etc., can solve the problems of inconvenient on-site construction and installation of workers, stress concentration, etc., and achieve the effect of increasing connection stability, large node rigidity, and reducing installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

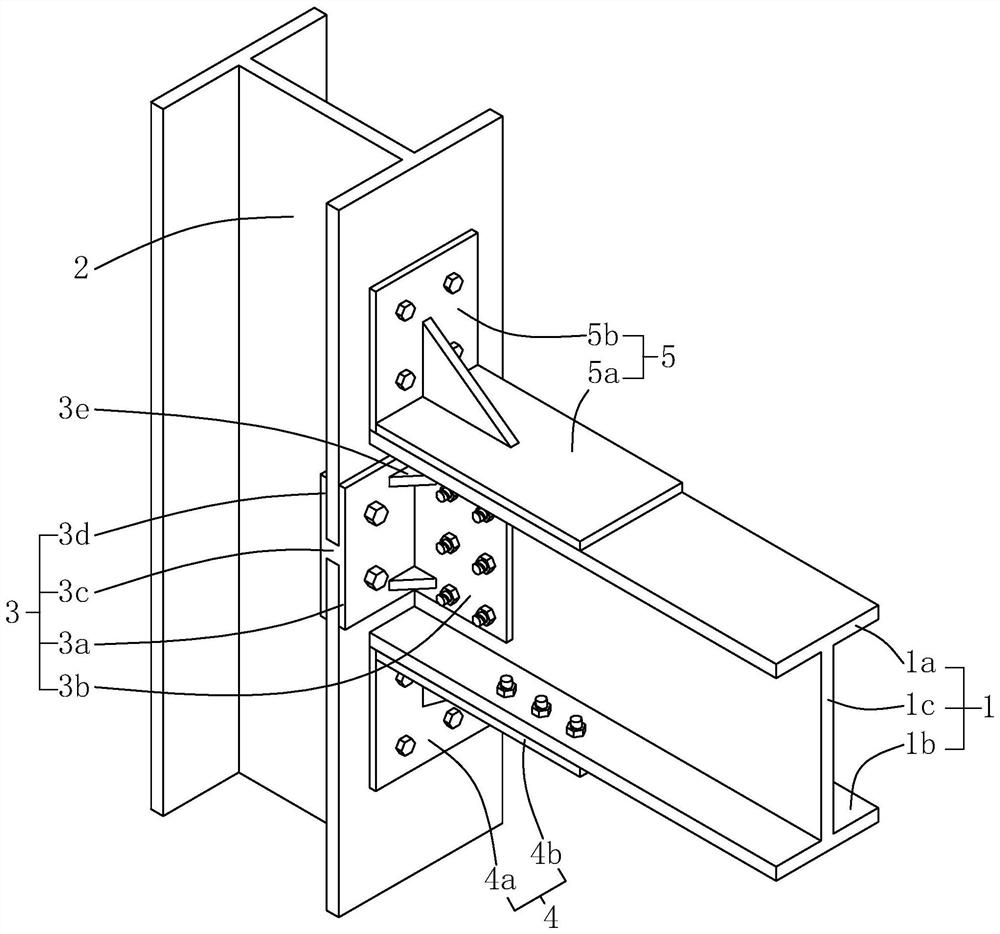

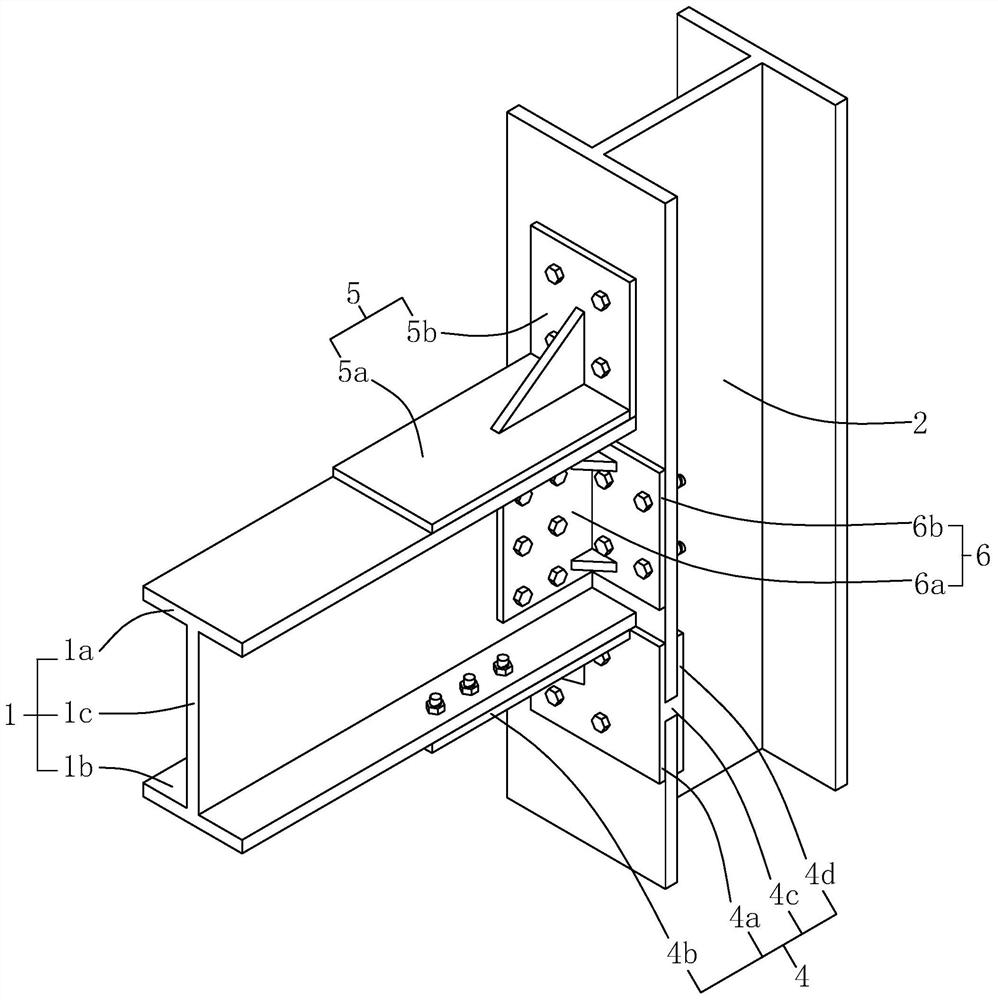

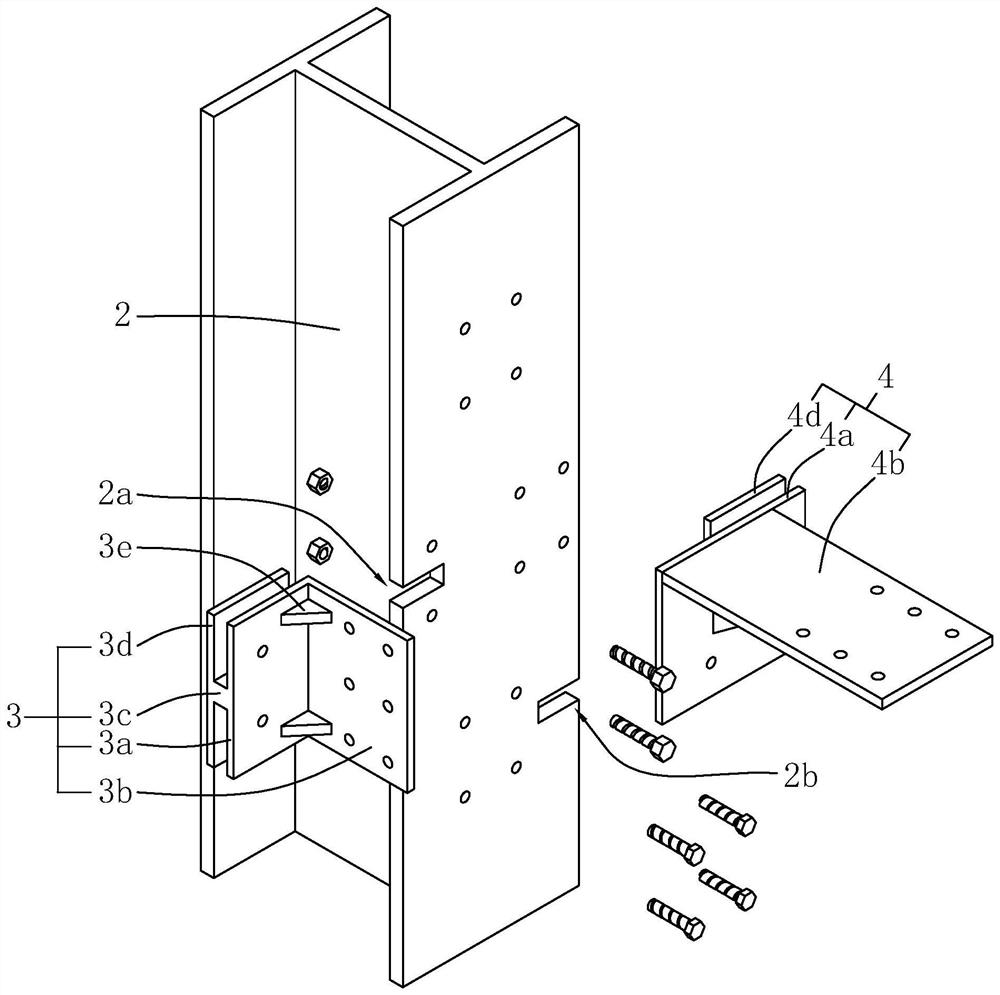

[0039] refer to figure 1 and figure 2 , which is an H-shaped steel beam and H-shaped steel column strong shaft assembled node disclosed in the present invention, including H-shaped steel beam 1, H-shaped steel column 2, first connecting piece 3, second connecting piece 4, and third connecting piece 5 and the fourth connector 6; wherein, the H-shaped steel beam 1 includes a horizontal upper flange 1a, a lower flange 1b and a vertical web 1c; the H-shaped steel column 2 is vertically arranged, and the H-shaped steel column A wing plate of 2 is used to connect with the H-shaped steel beam 1.

[0040] refer to figure 1 and image 3 , the first connecting piece 3 is installed on the wing plate of the H-shaped steel column 2, the first connecting piece 3 includes a first L-shaped plate, a first plug-in block 3c and a first limiting plate 3d, specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com