Cleaning agent for OLED mask and cleaning process thereof

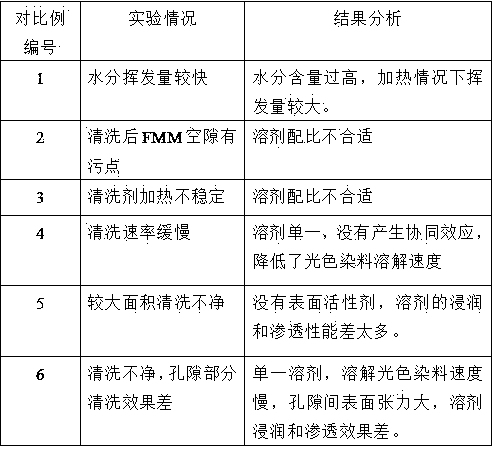

A technology of cleaning agent and mask, which is applied in the field of fine metal mask cleaning agent preparation, can solve the problems of low dissolution and stripping effect of small molecule RGB organic dyes, increased cost of OLED display preparation, and affecting the service life of FMM, etc. Achieve the effect of excellent cleaning effect, excellent cleaning effect and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

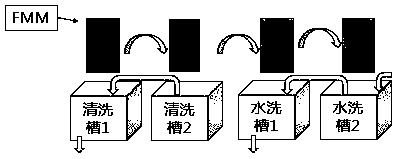

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: the cleaning agent that OLED mask plate is used

[0079] Consists of the following components in weight percent:

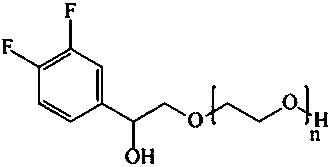

[0080] Diethylene glycol butyl ether 35%, tetrahydrofurfuryl alcohol 35%, 3.4-difluorophenylhydroxypoly(10) ethylene oxide (in formula I, n is 10) 3%, deionized water 27%.

Embodiment 2

[0081] Embodiment 2, the cleaning agent that OLED mask plate is used

[0082] Consists of the following components in weight percent:

[0083] Propylene glycol methyl ether 30%, tetrahydrofurfuryl alcohol 35%, 3.4-difluorophenylhydroxypoly(10) ethylene oxide (in formula I, n is 10) 5%, deionized water 30%.

Embodiment 3

[0084] Embodiment 3, the cleaning agent that OLED mask plate is used

[0085] Consists of the following components in weight percent:

[0086] Dipropylene glycol monomethyl ether 40%, tetrahydrofurfuryl alcohol 35%, 3.4-difluorophenyl hydroxyl poly(12) ethylene oxide (in formula I, n is 12) 3%, deionized water 22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com