A liquid-phase hydrogenation process and liquid-phase hydrogenation reactor

A liquid-phase hydrogenation and hydrogenation reaction technology, which is used in the petroleum industry, chemical instruments and methods, and hydrocarbon oil treatment, etc., can solve the problems of local hot spots, cannot be removed in time, and affects the service life of catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

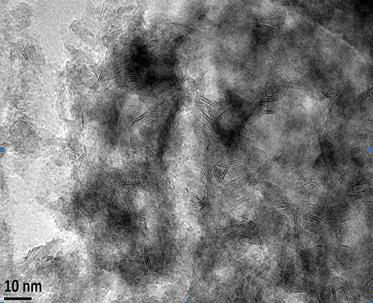

[0045] The preparation method of catalyst B: put 125 g (dry basis 80) of macroporous alumina dry rubber powder in a rolling pan, add 2 g of scallop powder, and spray it to the alumina carrier in the rolling pan under the condition of rotation Spray 80mL containing 21.5g molybdenum trioxide, 21.1g basic cobalt carbonate, 0.6g ethylene glycol, 2.0g citric acid, 20g 10% nitric acid, 0.6g sodium methylene bis-naphthalene sulfonate, 52.7g aluminum sulfate Aqueous solution, after the solution is sprayed, continue to rotate in a rolling pot for 30 minutes, knead, shape, dry at 110°C for 4 hours, and roast at 550°C for 3 hours to obtain catalyst B in oxidation state. The oxidized catalyst B was vulcanized by an in-vehicle vulcanization process. The amount of vulcanizing agent introduced was 120% of the theoretical sulfur demand of the catalyst. The vulcanization process was carried out by temperature programming, and the temperature was raised to 320°C for 10 hours to obtain the finish...

Embodiment 1

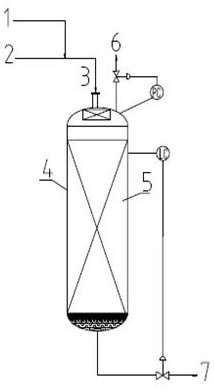

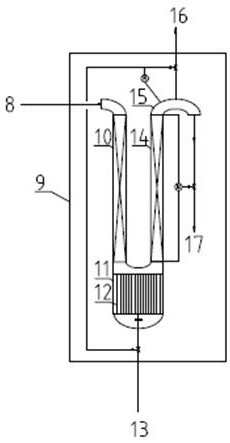

[0058] Attached figure 2 In the liquid-phase hydrogenation reactor and the liquid-phase hydrogenation reaction process, the amount of hydrogen in the hydrogen-dissolving raw material oil is 0.116% of the quality of the raw material oil; The amount of hydrogen injected into the micrometer is 0.068% of the mass of the raw oil. The reaction conditions in the hydrogenation reaction section are as follows: the reaction temperature is 240-260°C, the reaction pressure is 3.3MPaG, and the liquid hourly volume space velocity is 4.5h -1 ; The reaction conditions in the air stripping section are as follows: the reaction temperature is 240-260°C, the reaction pressure is 3.5MPaG, and the liquid hourly volume space velocity is 86h -1 . The diameter of the hydrogenation reaction section is 200mm, the height is 3050mm, and the aspect ratio is 12.2:1; the diameter of the horizontal section is 2000mm, the length is 2000mm, and the aspect ratio is 1:1; the diameter of the hydrogenation react...

Embodiment 2

[0060] Attached figure 2 In the liquid-phase hydrogenation reactor and liquid-phase hydrogenation reaction process shown, the amount of hydrogen in the hydrogen-dissolving feedstock oil is 0.100% of the mass of the feedstock oil; the membrane tube microdisperser disperses the hydrogen into 500nm hydrogen bubbles, and The amount of hydrogen injected into the micrometer is 0.08% of the mass of the raw oil, and the hydrogen-oil mixing equipment adopts a membrane tube micro-disperser. The reaction conditions in the hydrogenation reaction section are as follows: the reaction temperature is 240-260°C, the reaction pressure is 3.6MPaG, and the liquid hourly volume space velocity is 4.5h -1 ; The reaction conditions of the air stripping section are as follows: the reaction temperature is 240-260°C, the reaction pressure is 3.0MPaG, and the liquid hourly volume space velocity is 57h -1 The diameter of the hydrogenation reaction section is 500mm, the height is 2.5 meters, and the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com