A kind of anti-shock thickening polyurethane hydrogel and preparation method thereof

A polyurethane and hydrogel technology, applied in the field of impact-resistant shear thickening polyurethane hydrogel and its preparation, can solve problems such as short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1) Weigh 70-95% PEG into a round-bottomed flask, and fully remove water by rotary evaporation in a vacuum oil bath. Add the above-mentioned PEG and 3-25% DBTDL into the three-necked flask, vacuumize and ventilate with N 2 Protect, heat in an oil bath and stir with magnetic force to make it fully melt, add 0.5-1% IPDI and 1.5-4% stannous octoate into the flask, react for a certain period of time and cool down to obtain PU.

[0055] 2) Add 4ml of AOI into the round bottom flask, stir it with magnetic force, and get the reaction product (PU-AOI) after reacting for a certain period of time, precipitate with anhydrous ether, wash thoroughly and dry in vacuum.

[0056] 3) Weigh 60-95% (PU-AOI), 4-39% ABCN into the three-necked flask, vacuum and ventilate 2 For protection, add a certain amount of steamed anhydrous toluene, stir magnetically to make it fully dissolved, add 1% MPTDMS to the flask, stir magnetically in an oil bath, and react for a certain period of time to obtai...

Embodiment 2

[0067] 1) Weigh 70-95% PEG into a round-bottomed flask, and fully remove water by rotary evaporation in a vacuum oil bath. Add the above-mentioned PEG and 3-25% DBTDL into the three-necked flask, vacuumize and ventilate with N 2 Protection, heating with oil bath and magnetic stirring to make it fully melt, add 0.5-1% IPDI, 1.5-4% stannous octoate into the flask, react for a certain period of time and cool down to obtain PU;

[0068] 2) Add 8ml of AOI to the flask, stir with magnetic force, and react for a certain period of time to obtain the reaction product (PU-AOI), which is precipitated with anhydrous ether, fully washed and vacuum-dried.

[0069] 3) Weigh 60-95% (PU-AOI), 4-39% ABCN into the three-necked flask, vacuum and ventilate 2 For protection, add a certain amount of steamed anhydrous toluene, stir magnetically to make it fully dissolved, add 1% MPTDMS to the flask, stir magnetically in an oil bath, and react for a certain period of time to obtain the product (PU-AO...

Embodiment 3

[0080] 1) Weigh 70-95% PEG into a round-bottomed flask, and fully remove water by rotary evaporation in a vacuum oil bath. Add the above-mentioned PEG and 3-25% DBTDL into the three-necked flask, vacuumize and ventilate with N 2 Protection, magnetic stirring in an oil bath to make it fully melt, add 0.5-1% IPDI, 1.5-4% stannous octoate into the flask, cool down after a certain period of time to obtain PU;

[0081] 2) Add 8ml of AOI to the flask, stir it with magnetic force, and react for a certain period of time to obtain the product (PU-AOI), which is precipitated with anhydrous ether, fully washed and vacuum-dried.

[0082] 3) Weigh 60-95% (PU-AOI), 4-39% ABCN into the three-necked flask, vacuum and ventilate 2 For protection, add a certain amount of steamed anhydrous toluene, stir magnetically to make it fully dissolve, add 1% MPTDMS to the flask, stir magnetically in an oil bath, and react to the product (PU-AOI)-MPTDMS after a certain period of time. The product was pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

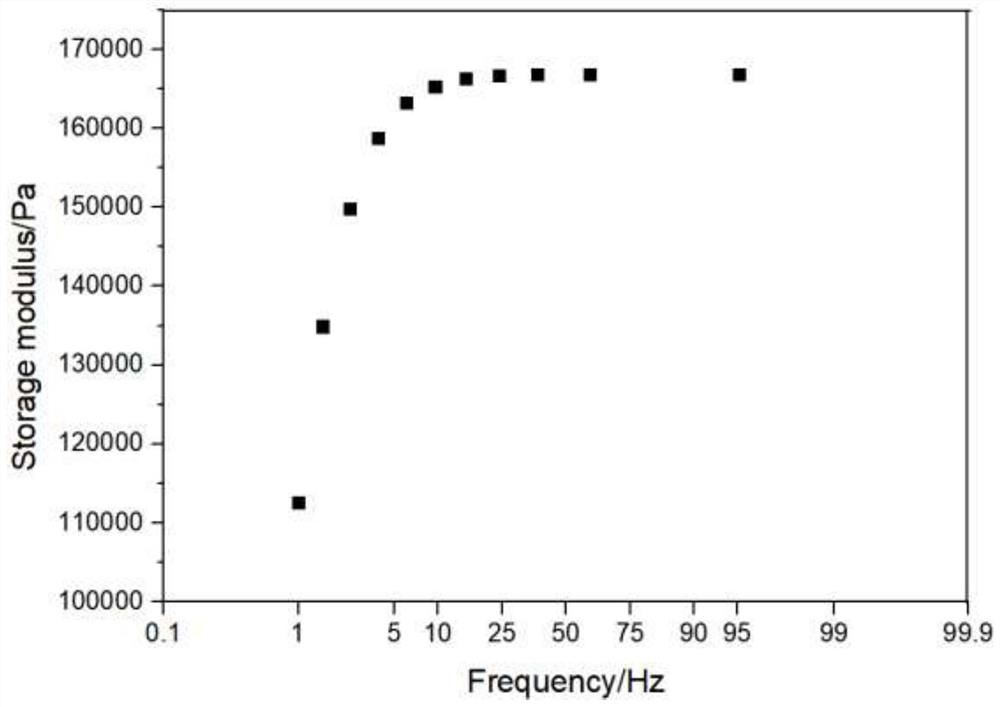

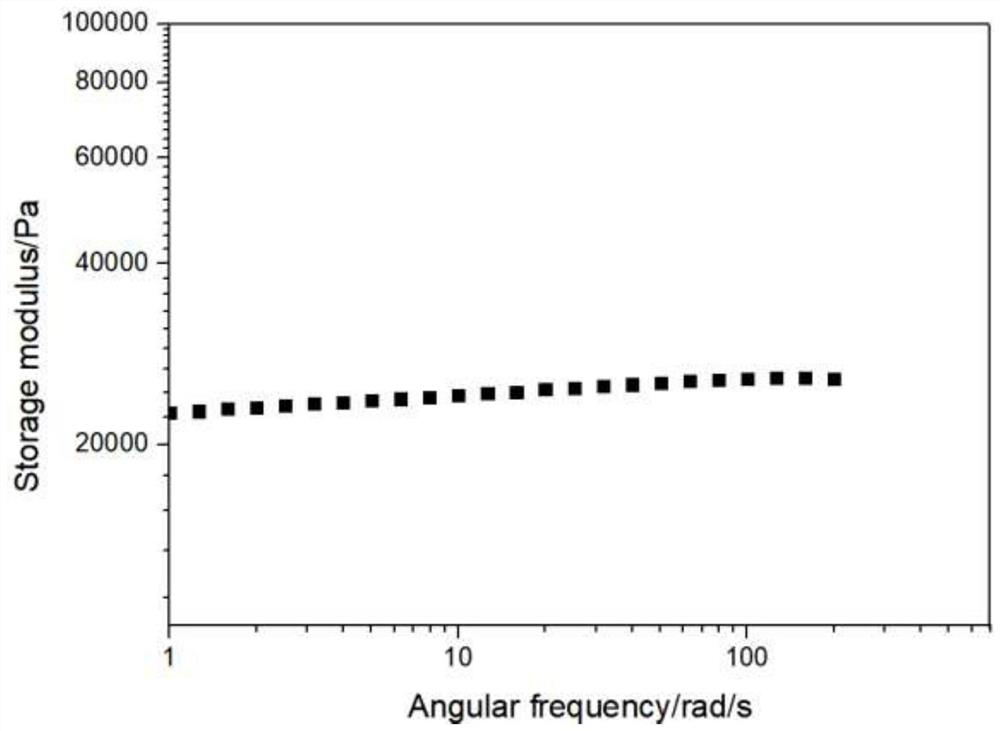

| storage modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com