A kind of preparation method of concrete polycarboxylate slump retaining agent

A technology of polycarboxylic acid and slump-retaining agent, applied in the field of building admixtures, can solve the problems of poor workability and bleeding of concrete, and achieve the effects of good workability, slowing down hydration speed, and guaranteeing dispersion and dispersion retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

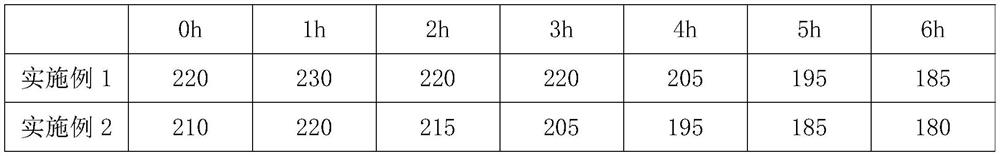

Embodiment 1

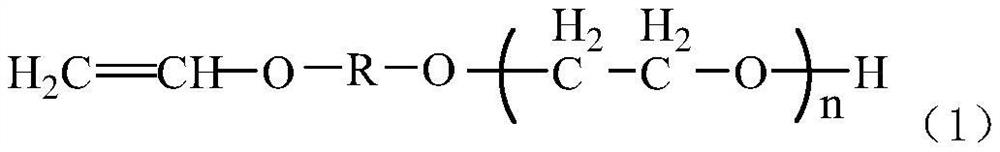

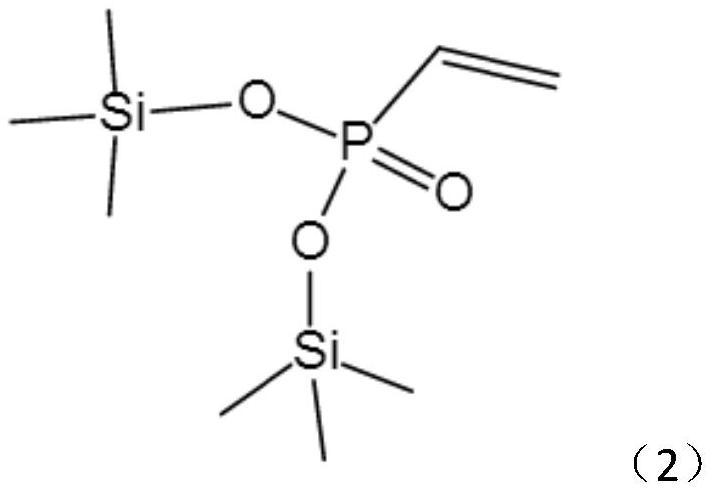

[0036] According to formula: 100 parts by weight of unsaturated polyether (structure shown in formula (1), wherein R is -CH 2 CH 2 -, n=25.2), 7 parts by weight of acrylic acid, 12 parts by weight of hydroxyethyl acrylate and 3 parts by weight of bistrimethylsilylated vinyl phosphate.

[0037] Add unsaturated polyether and 100 parts by weight of water into the reactor, stir and dissolve, keep the temperature at 15±2°C, add 12 parts by weight of 10% potassium persulfate aqueous solution, stir evenly, add acrylic acid, hydroxyethyl acrylate , a mixed solution composed of bistrimethyl silylated vinyl phosphate and 0.8 parts by weight of 2-mercaptoethanol, stir evenly, dropwise add 4 parts by weight of aqueous sodium bisulfite solution with a concentration of 15 wt% within 1 hour, add dropwise After the reaction was performed at a constant temperature of 30±2° C. for 1 hour, a copolymerization product 1 was obtained.

[0038] In 100 parts by weight of copolymerization product 1,...

Embodiment 2

[0040]According to formula: 100 parts by weight of unsaturated polyether (structure shown in formula (1), wherein R is -CH 2 CH 2 CH 2 -, n=47.1), 5 parts by weight of methacrylic acid, 15 parts by weight of hydroxyethyl methacrylate and 1 part by weight of bistrimethylsilylated vinyl phosphate.

[0041] Add unsaturated polyether and 200 parts by weight of water into the reaction kettle, stir and dissolve, keep the temperature at 10±2°C, add 10 parts by weight of 10% potassium persulfate aqueous solution, stir evenly, add methacrylic acid, methyl A mixed solution consisting of hydroxyethyl acrylate, bis-trimethylsilyl vinyl phosphate and 1 part by weight of 2-mercaptoacetic acid was stirred evenly, and 6 parts by weight of sodium bisulfite with a concentration of 10wt% was added dropwise within 1.5 hours The aqueous solution was added dropwise, and the reaction was carried out at a constant temperature of 25±2° C. for 1.5 hours to obtain a copolymerization product 2.

[004...

Embodiment 3

[0044] According to formula: 100 parts by weight of unsaturated polyether (structure shown in formula (1), wherein R is -CH 2 CH 2 CH 2 CH 2 -, n=55.3), 10 parts by weight of maleic acid, 10 parts by weight of hydroxypropyl acrylate and 5 parts by weight of bistrimethylsilylated vinyl phosphate.

[0045] Add unsaturated polyether and 300 parts by weight of water into the reactor, stir and dissolve, keep the temperature at 18±2°C, add 12 parts by weight of 10% potassium persulfate aqueous solution, stir evenly, add maleic acid, acrylic acid hydroxyl A mixed solution consisting of propyl ester, bis-trimethyl silylated vinyl phosphate and 1.2 parts by weight of 2-mercaptoacetic acid was stirred evenly, and 6 parts by weight of an aqueous solution of L-ascorbic acid with a concentration of 10 wt % was added dropwise within 2 hours. After the addition was completed, the reaction was performed at a constant temperature of 27±2° C. for 2 hours to obtain a copolymerization product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com