Method for preparing nicotine sulfate

A technology of nicotine sulfate and nicotine, which is applied in the field of tobacco chemistry, can solve the problems of no application reports for the preparation of nicotine sulfate, low concentration energy consumption, etc., and achieve the effect of poor interception efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

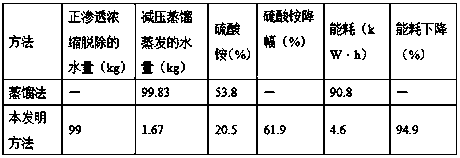

Embodiment 1

[0023] A method for preparing nicotine sulfate, wherein the tobacco raw material or its water extract is steam-distilled under alkaline conditions to obtain a low-concentration nicotine distillate; it also includes the following steps:

[0024] Step (1), the low-concentration nicotine distillate is concentrated by forward osmosis, and concentrated to a nicotine concentration of 5% in the retentate at 5°C-25°C;

[0025] Step (2), adding sulfuric acid with a mass percentage concentration of 5% to the retained liquid, reacting with nicotine in the retained liquid to obtain a nicotine sulfate solution, and then evaporating and concentrating to obtain sulfuric acid with a mass percentage concentration of 40% nicotine.

[0026] The mass percent content of nicotine in the low-concentration nicotine distillate is 0.05%.

[0027] In the forward osmosis concentration, the aquaporin membrane is used as the forward osmosis concentration membrane, the inorganic salt is used as the extract...

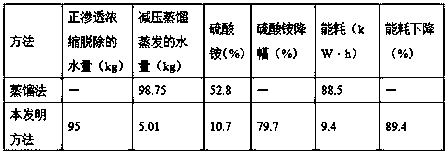

Embodiment 2

[0030] A method for preparing nicotine sulfate, wherein the tobacco raw material or its water extract is steam-distilled under alkaline conditions to obtain a low-concentration nicotine distillate; it also includes the following steps:

[0031] Step (1), the low-concentration nicotine distillate is concentrated by forward osmosis, and concentrated to a nicotine concentration of 20% in the retentate under the condition of 20°C-45°C;

[0032] Step (2), adding sulfuric acid with a mass percentage concentration of 40% to the retained liquid, reacting with nicotine in the retained liquid to obtain a nicotine sulfate solution, and then evaporating and concentrating to obtain sulfuric acid with a mass percentage concentration of 60% nicotine.

[0033] The mass percentage of nicotine in the low-concentration nicotine distillate is 1%.

[0034] The said forward osmosis concentration uses a polyamide membrane as a forward osmosis concentration membrane, uses an inorganic salt as a draw...

Embodiment 3

[0037] A method for preparing nicotine sulfate, wherein the tobacco raw material or its water extract is steam-distilled under alkaline conditions to obtain a low-concentration nicotine distillate; it also includes the following steps:

[0038] Step (1), the low-concentration nicotine distillate is concentrated by forward osmosis, and concentrated to a nicotine concentration of 15% in the retentate under the condition of 10°C-35°C;

[0039] Step (2), adding sulfuric acid with a mass percentage concentration of 20% to the retained liquid, reacting with nicotine in the retained liquid to obtain a nicotine sulfate solution, and then evaporating and concentrating to obtain sulfuric acid with a mass percentage concentration of 50% nicotine.

[0040] The mass percentage of nicotine in the low-concentration nicotine distillate is 0.5%.

[0041] The said forward osmosis concentration uses a polyamide membrane as a forward osmosis concentration membrane, uses an inorganic salt as a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com