Method for inhibiting generation of aryl methyl ether by phenol ortho-methylation reaction

An aryl methyl ether, methylation technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve problems such as increasing energy consumption, increasing separation equipment, increasing equipment investment costs, etc. Low, simple process, the effect of inhibiting the production of aryl methyl ether

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

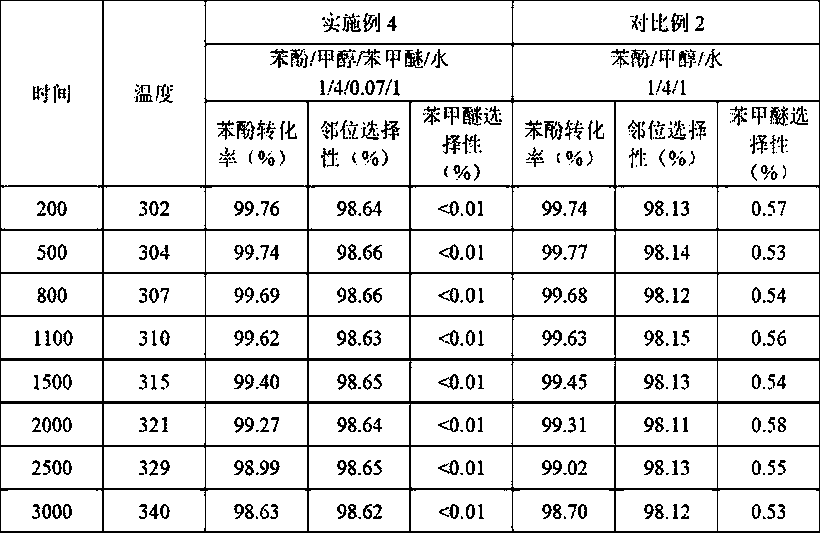

Examples

Embodiment 1

[0016] Put 200g of the composite ortho-methylation catalyst into a stainless steel fixed-bed reactor with an inner diameter of Ф16mm. The raw materials are prepared according to the ratio of phenol / methanol / anisole / water molar ratio of 1 / 4 / 0.03 / 0.5, and the raw materials are pumped Injected into the reactor, at a pressure of 0.2MPa and a temperature of 310°C, the tail gas produced by the reaction is circulated by a carrier gas booster, and the carrier gas circulation volume is controlled by a regulating valve to be 30 L / h. The excess tail gas discharge device, the feed quality The air speed is 0.8h -1 Under the conditions, the reaction ran stably for 200 hours, and the reaction products were collected after cooling and sampled and analyzed. The average conversion rate of phenol was 99.6%, the average selectivity of 2,6-xylenol was 87.6%, the total ortho position selectivity was 98.6%, and anisole Selectivity 0.02% (deduct the addition of raw materials during calculation).

Embodiment 2

[0020] Put 200g of the composite ortho-methylation catalyst into a stainless steel fixed-bed reactor with an inner diameter of Ф16mm, and the raw material is 1 / 3 according to the molar ratio of 2,5-xylenol / methanol / 2,5-dimethylanisole / water The ratio of / 0.05 / 3 is prepared, and the raw materials are pumped into the reactor. The pressure is normal pressure and the temperature is 300°C. 20 L / h, excess exhaust gas discharge device, feed mass space velocity is 1.0h -1 Under the conditions, the reaction ran stably for 200 hours, and the reaction products were collected after cooling and sampled and analyzed. The average conversion rate of 2,5-xylenol was 98.12%, the average selectivity of 2,3,6-tricresol was 99.33%, The selectivity of methyl anisole is 0.01% (the added part in the raw material is deducted from the calculation). As a contrast, under the same conditions, the reaction sampling analysis without adding 2,5-dimethylanisole, the average conversion rate of 2,5-xylenol was...

Embodiment 3

[0022] Put 200g of the composite ortho-methylation catalyst into a stainless steel fixed-bed reactor with an inner diameter of Ф16mm, and prepare the raw materials according to the molar ratio of p-cresol / methanol / p-methylanisole / water as 1 / 5 / 0.1 / 4 , pump the raw materials into the reactor, at a pressure of 0.8MPa and a temperature of 300°C, the tail gas generated by the reaction is circulated by a carrier gas booster, and the carrier gas circulation volume is controlled to 70 L / h by a regulating valve, and the excess tail gas is discharged device, the feed mass space velocity is 2.0h -1 Under the conditions, the reaction ran stably for 200 hours, and the reaction products were collected after cooling and sampled and analyzed. The average conversion rate of p-cresol was 99.90%, the average selectivity of 2,4,6-tricresol was 90.57%, and the total ortho position selectivity was 99.68%. , p-methyl anisole selectivity -0.01% (the added part of the raw material is deducted during c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com