Method for preparing potassium chloride from carnallite raw ore

A technology of carnallite and potassium chloride, applied in alkali metal chlorides, potassium fertilizers, inorganic fertilizers, etc., can solve the problems of reducing the grade of potassium chloride, reducing the utilization rate of carnallite, and low grade of potassium chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to express the purpose, technical solution and effect of the present invention more clearly, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

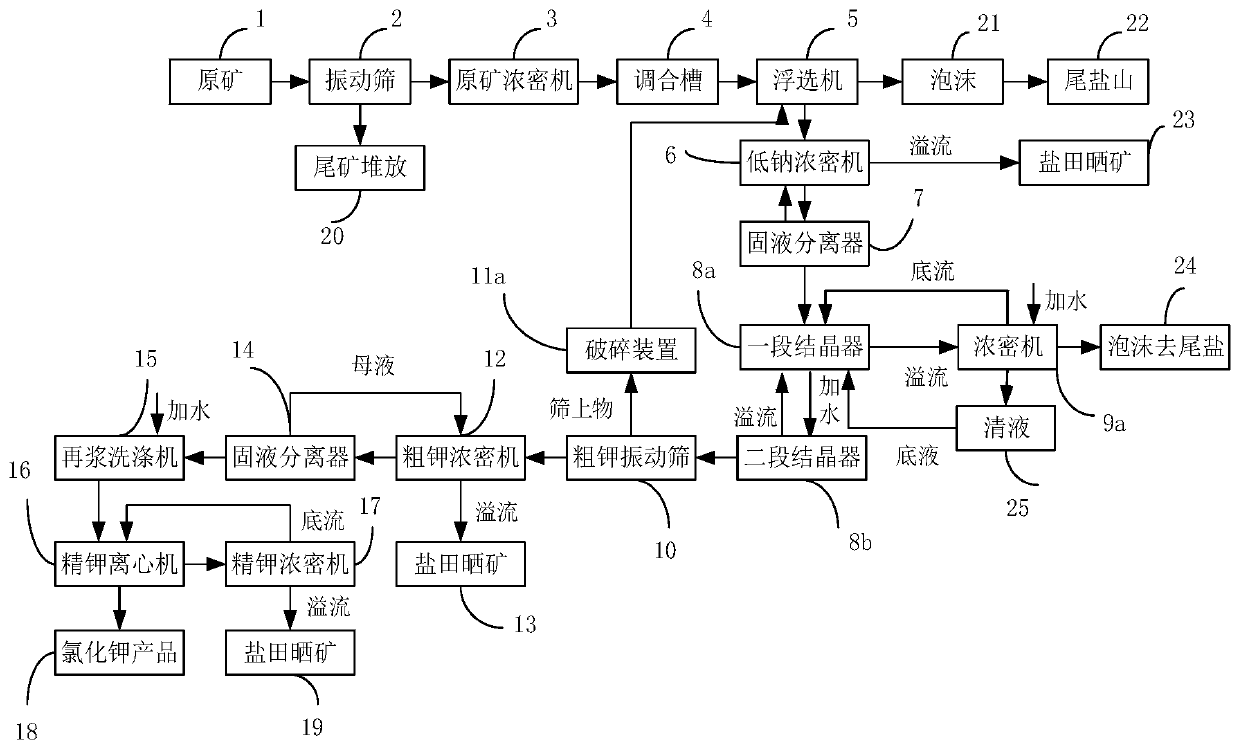

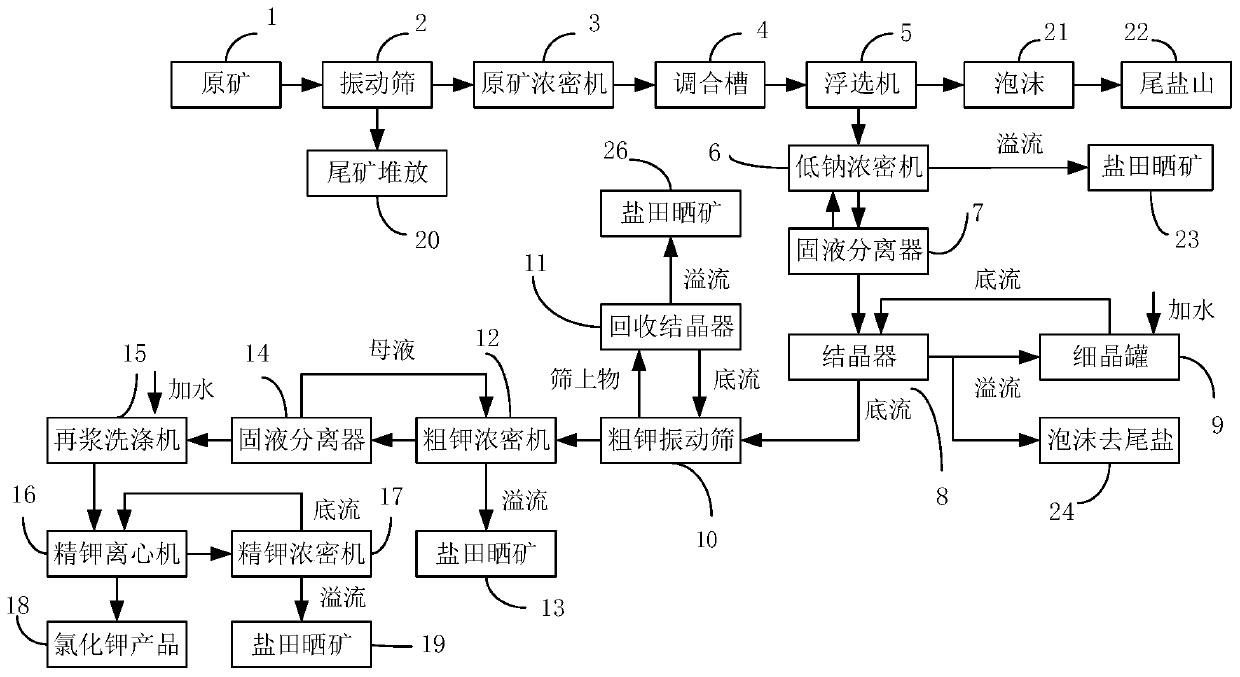

[0027] figure 1 It is a process roadmap for producing potassium chloride from carnallite raw ore of the present invention. The invention is in image 3 Improve on the basis of , replace prior art with crushing device 11a ( image 3 ) in the recovery crystallizer 11, using physical methods to crush the oversize into small particles that meet the size of the flotation particle size, and the crushed particles return to the flotation machine 5 for secondary flotation to remove chlorine that was not removed in the previous process Sodium chloride particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com