PVC plate laminated film edge cutting device

A coating and edge technology, which is applied in the field of PVC sheet coating edge cutting device, can solve the problems of material waste and low cutting efficiency of excess film, and achieve the effects of reducing wear, improving cutting and removing efficiency, and smooth adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

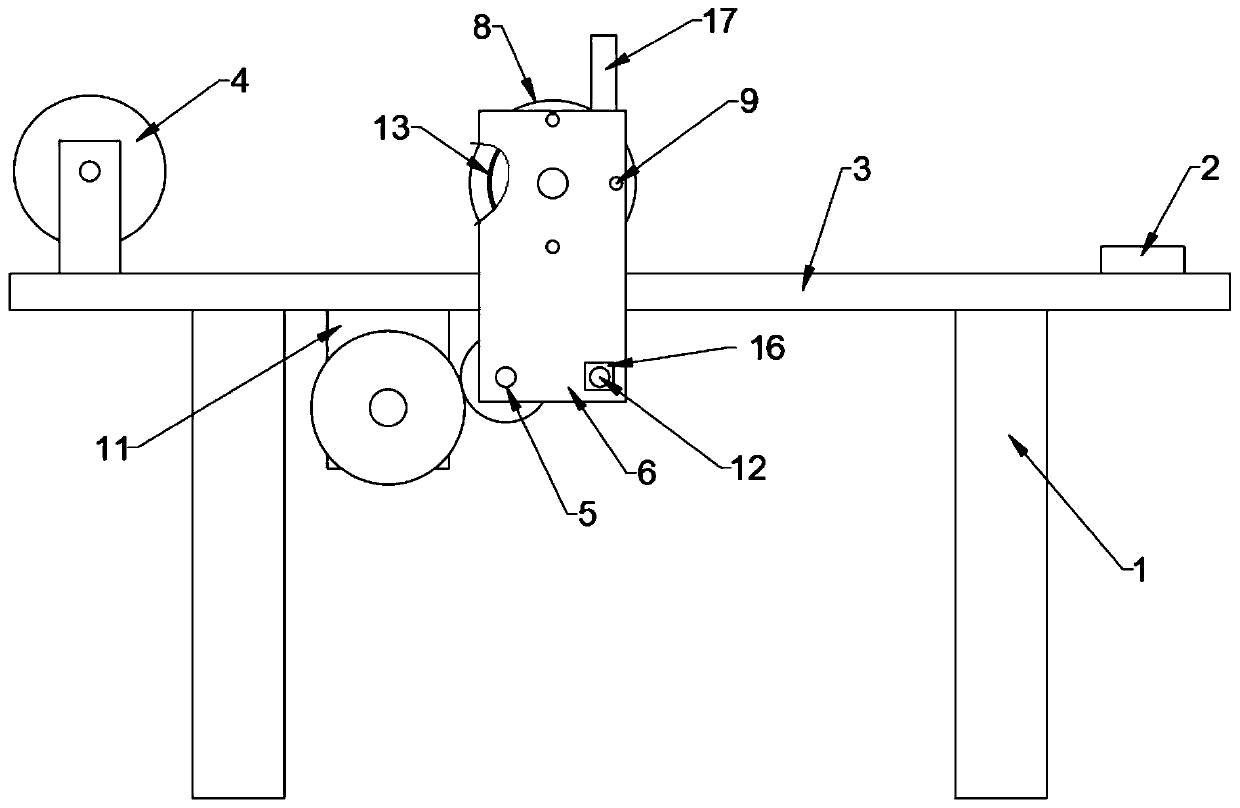

[0030] This embodiment, as a basic embodiment of the present invention, discloses a device for cutting off the edge of PVC sheet coating, the specific structure is as follows figure 1 As shown, it includes a frame 1, the frame 1 is also provided with a PLC controller 2, and the frame 1 is also fixedly provided with a working platform 3, and the inlet end of the working platform 3 is provided with a feeding roller 4; The bottom surface of 3 is provided with an adjusting screw 5 through the rotation of the bearing seat, and at the same time, a rotating motor 11 is fixedly installed. The rotating motor 11 is connected with the adjusting screw 5 through a transmission gear, and the screw threads at both ends of the adjusting screw 5 have opposite directions of rotation. , the two ends of which are connected with the adjustment seat 6 with threaded buckles respectively, and the adjustment seat 6 is also slidingly connected with the sliding rod 12 fixed on the bottom of the work plat...

Embodiment approach 2

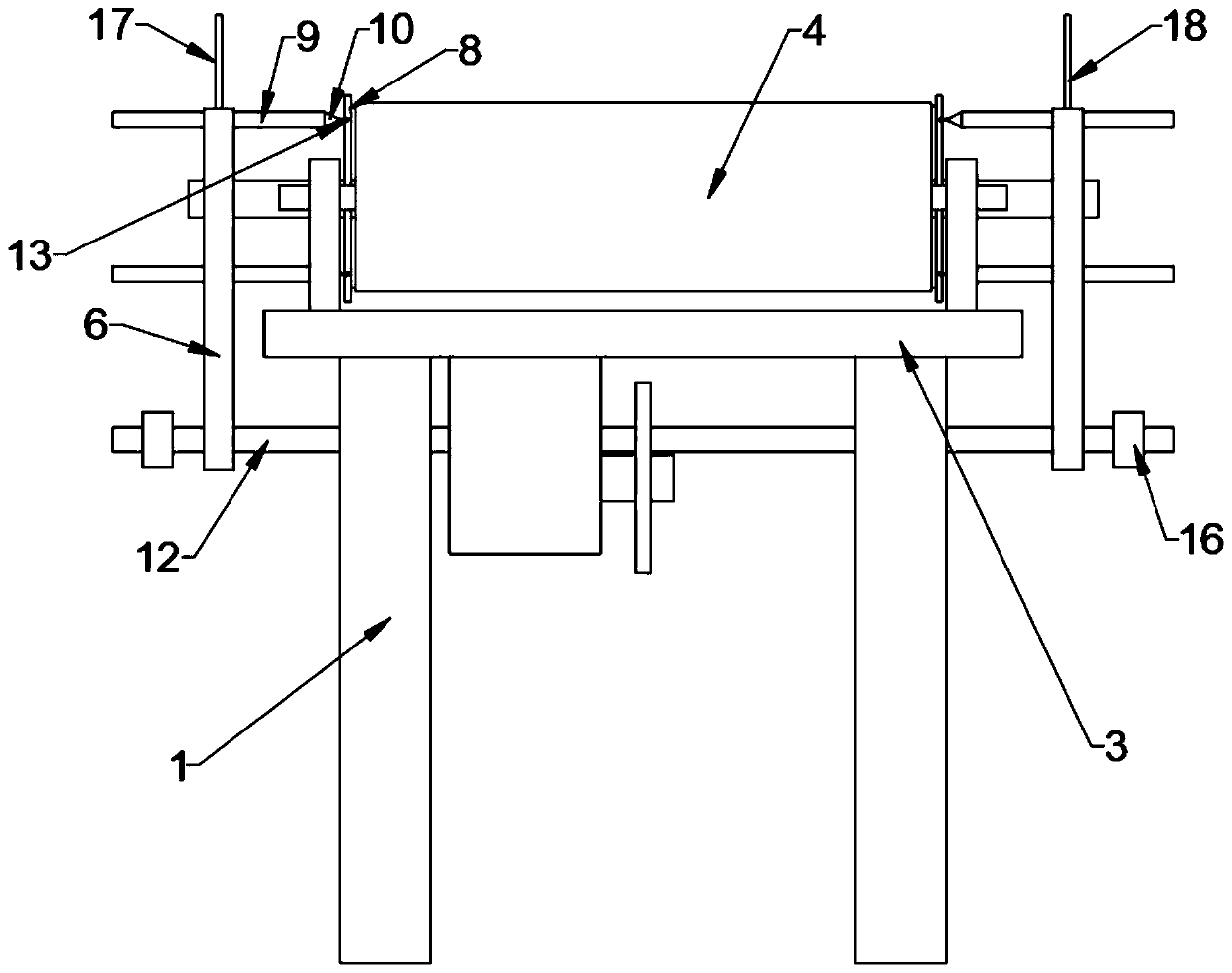

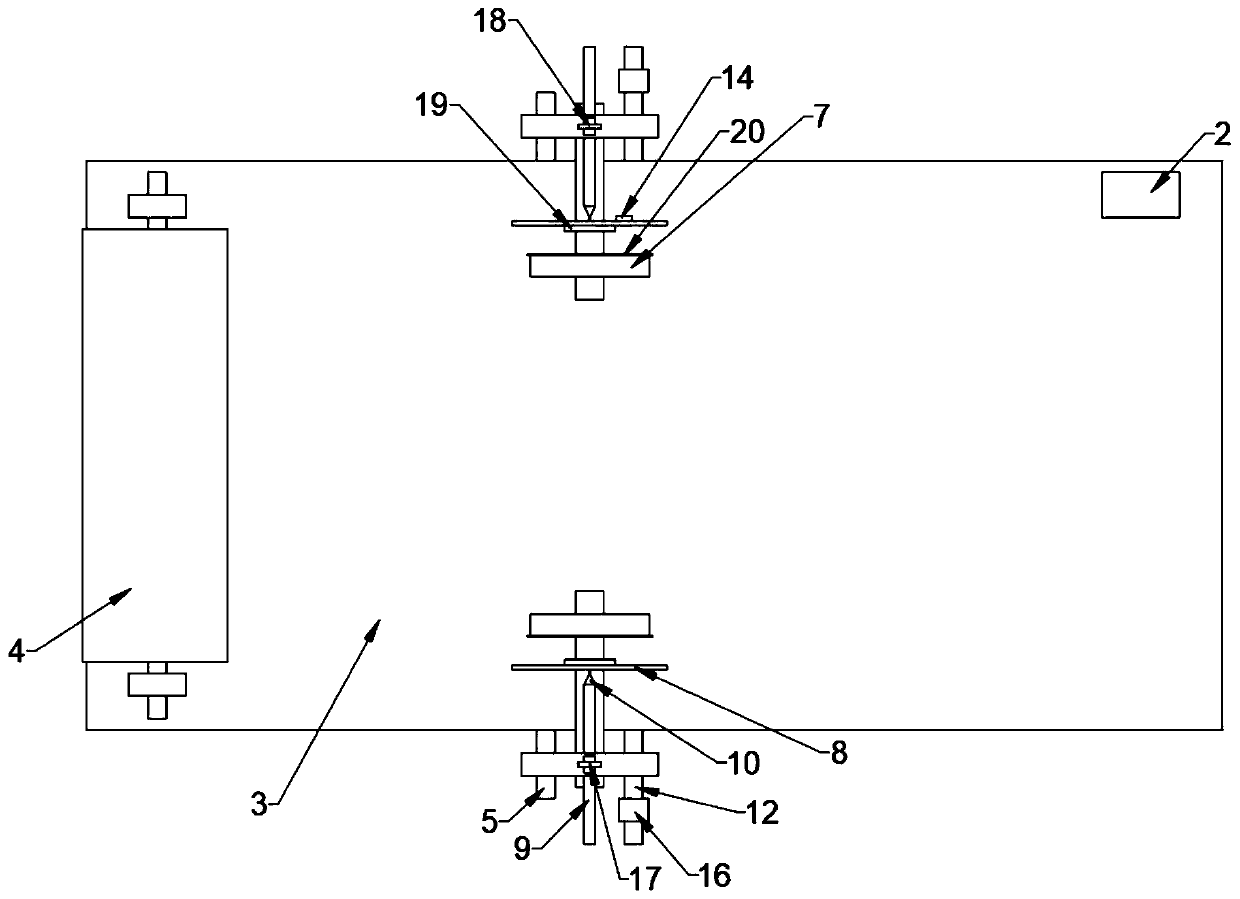

[0032] This embodiment, as a preferred embodiment of the present invention, discloses a device for cutting off the edge of PVC sheet coating, the specific structure is as follows Figure 1-4 As shown, it includes a frame 1, on which an adjustment screw 5 is rotated, and the two ends of the adjustment screw 5 are connected with an adjustment seat 6 through a threaded thread in the opposite direction, and the adjustment seat 6 is fixed Four electric soldering irons 9 are provided, and the soldering iron tip 10 of the electric soldering iron 9 is inserted into the annular groove 13 of the hot cutter 8; at the same time, a temperature sensor 14 connected to the PLC controller 2 is also fixedly installed on the hot cutter 8, and the sliding rod 12 There are travel switches 16 connected to the PLC controller 2 at the two ends of the two ends; an infrared rangefinder 17 and a reflector 18 that cooperate with each other are arranged on the top of the two adjustment seats 6, and the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com