Paper recyclable material humidifying, shredding and extruding treatment method

A processing method and technology for recycled materials, which are applied in grain processing, presses, manufacturing tools, etc., can solve the problems of heavy dust pollution, high disposal costs, and low paper specific gravity, so as to increase the transfer volume, reduce costs, and increase paper production. The effect of specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

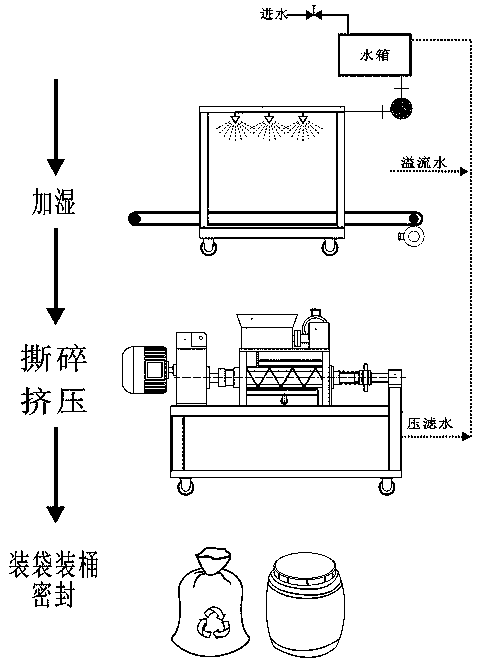

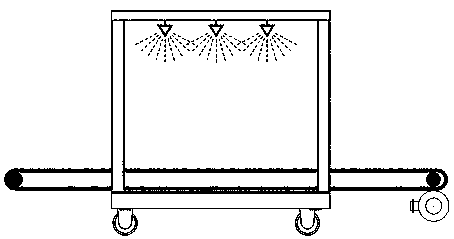

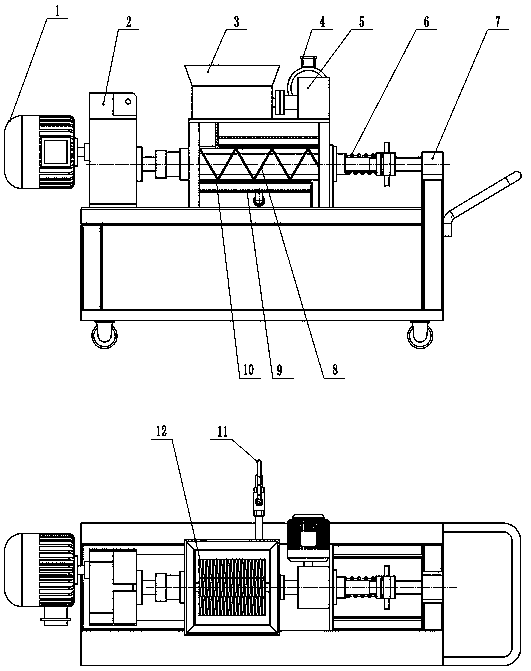

[0025] Such as figure 1 As shown, a method for humidifying and shredding extrusion processing of paper recyclables in the present invention is to transport paper recyclables to a humidifier, and its spray system sprays water to humidify paper recyclables. After humidification and mixing, the moisture If the content is high, the paper will appear soft, with low stiffness, low corrugation and bonding quality, effectively reducing the difficulty of shredding and extrusion, reducing the energy consumption of the shredding and extruding machine, and the shredding and extruding machine is sprayed on paper recyclables. After spraying and humidifying, first shred into small pieces, then squeeze to compact the gaps in the paper blocks, filter out the excess water, collect and reuse, and store the shredded and squeezed paper blocks in bags and buckets, etc., in the same In terms of volume, it can store more paper recyclables without dust pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com