Slurry recycling device and method in building wall plastering construction

A technology for building walls and recycling devices, which is applied in construction, building structure, cleaning methods and appliances, etc. It can solve the problems of large contact area of cement blocks, difficulty in peeling off cement blocks, and increased difficulty in crushing, so as to improve recycling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

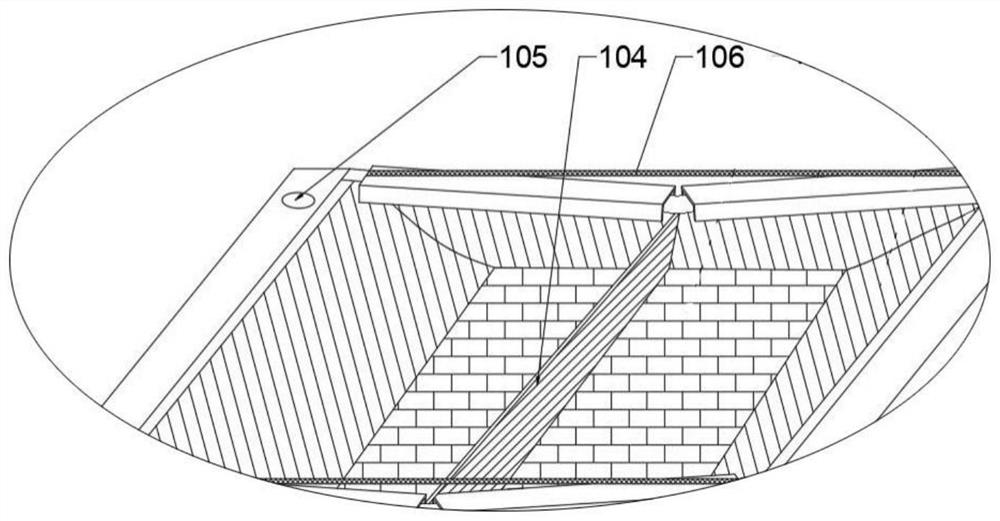

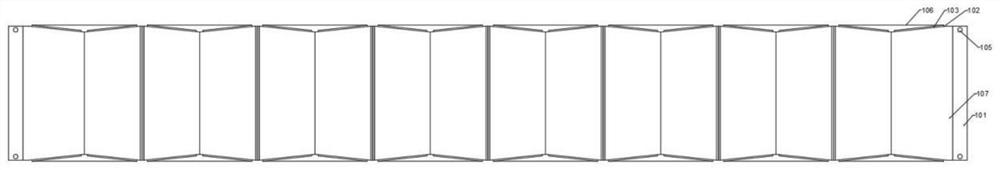

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. like figure 1 , 2 , 4, 5, 6, and 7, a slurry recovery device for building wall plastering works, including several collection boxes 1 and shaping rods 2, the collection box 1 includes two end plates 101, The plate 101 adopts an elongated plate-like structure, and a flexible side wall 102 and a flexible bottom plate 107 are arranged between the two end plates 101. The flexible side wall 102 and the flexible bottom plate 107 are respectively made of rubber material. The plate 101, the flexible side wall 102 and the flexible bottom plate 107 together constitute the collection cavity of the collection box 1, and a smooth film is arranged on the ...

Embodiment 2

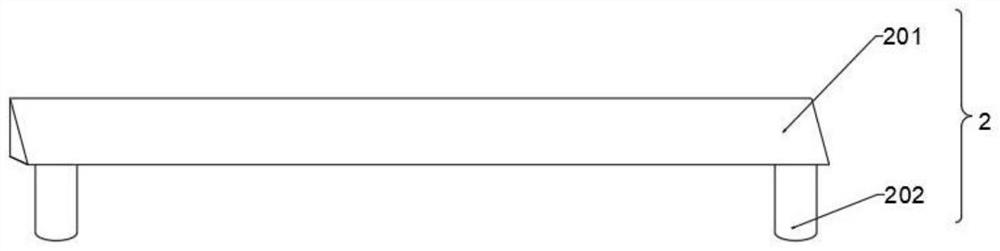

[0040] This embodiment is an improvement scheme made on the basis of Embodiment 1, and its main structure is the same as that of Embodiment 1. The improvement points are as follows: image 3 As shown, the guide rod 201 is composed of an outer rod body 2011 , an inner core 2012 and a locking bolt 2013 . After locking, the two latches 202 are respectively arranged at the ends of the outer rod body 2011 and the inner core 2012. Especially in continuous operation, when the two ends of the collection boxes 1 to be installed are on the outer end plates 101 of the collection boxes 1, When the distance between the insertion holes (105) changes, by adjusting the position of the inner core 2012 on the outer rod body 2011, the distance between the two pins 202 can be fine-tuned to increase the application scene of the device.

Embodiment 3

[0042] This embodiment is an improvement scheme made on the basis of Embodiment 1, and its main structure is the same as that of Embodiment 1. The improvement points are as follows: image 3 As shown, support rods 108 are provided below the outer end plates 101 of the collection boxes 1 at the two ends, and two support rods 108 are provided under each of the outer end plates 101. The bottom end of the collection cavity is off the ground, so that the collection cavity can accommodate more slurry falling off the building wall. The bottom of the support rod 108 is installed with a pulley 109. The pulley 109 adopts a universal wheel structure, which is convenient for the use of Movement of slurry recovery unit for building wall plastering works.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com