Mine stone crushing device

A crushing device and stone material technology, which is applied in the direction of water/sewage multi-stage treatment, smoke and dust removal, grain processing, etc., can solve the problems affecting the health of the operator, damage to the surrounding environment, short service life, etc., to meet the needs of automatic transportation, Ensures cleanliness and improves smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

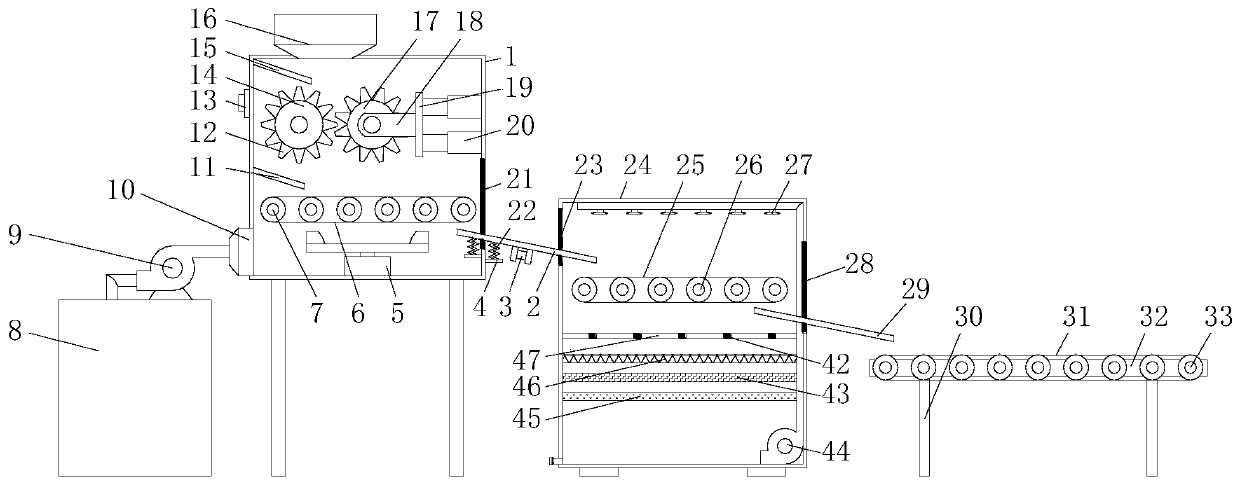

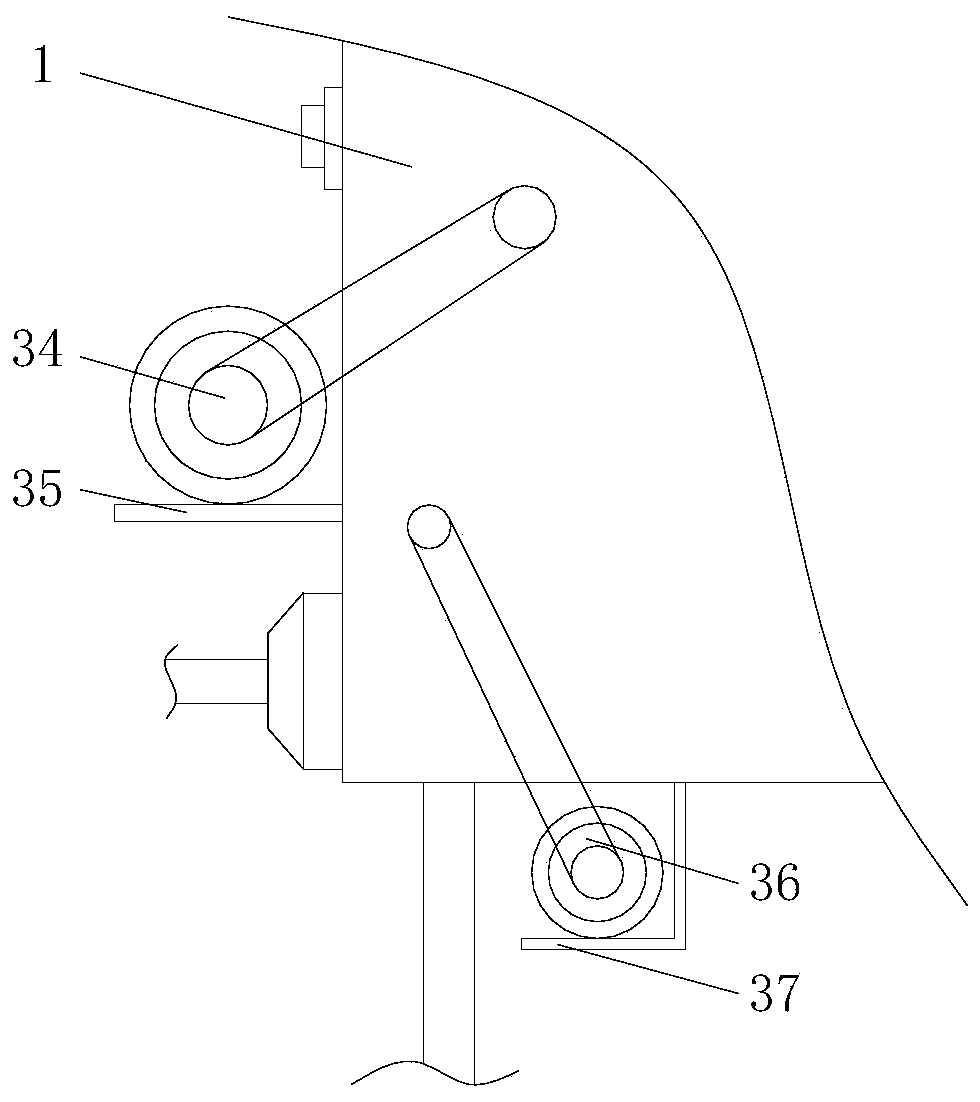

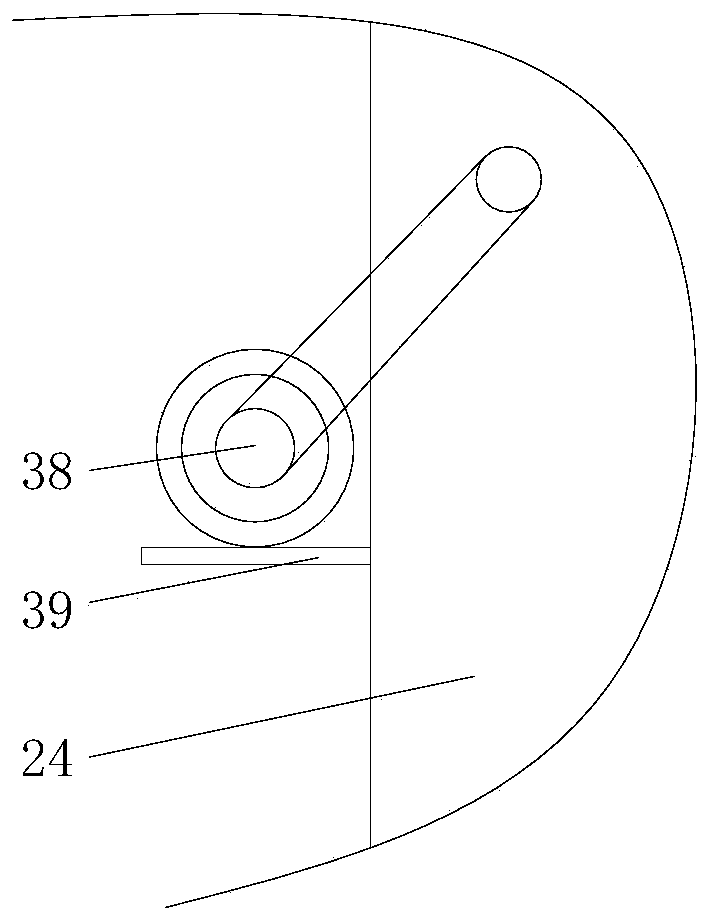

[0059] see Figure 1-6 , a crushing device for mine stone materials, comprising a crushing box 1, a dust collection box 8, a spray filter box 24 and a stone conveying platform 32, the left end of the crushing box 1 top is provided with a first feed port 16, and the left side of the crushing box 1 The upper end of the controller 13 is fixedly connected with a controller 13, and the outer surface of the controller 13 is fixedly connected with a first motor switch 131, a second motor switch 132, a third motor switch 133, a fourth motor switch 134, and a vibration motor from left to right. Switch 135, suction fan switch 136, water pump switch 137, centrifuge switch 138 and telescopic control button 139, the left side of the crushing box 1 inner cavity is fixedly connected with the first material blocking plate 15 and the second material blocking plate in sequence from top to bottom 11. The upper left end of the inner cavity of the crushing box 1 is movably installed with a driving...

Embodiment 2

[0068] A centrifugal dedusting equipment for mine stones, comprising a crushing box 1, a dust collection box 8, a spray filter box 24 and a stone conveying platform 32, the left end of the top of the crushing box 1 is provided with a first feed port 16, the left side of the crushing box 1 is The upper end is fixedly connected with a controller 13, and the outer surface of the controller 13 is fixedly connected with a first motor switch 131, a second motor switch 132, a third motor switch 133, a fourth motor switch 134, and a vibration motor switch from left to right. 135, suction fan switch 136, water pump switch 137, centrifuge switch 138 and telescopic control button 139, the left side of the crushing box 1 inner cavity is fixedly connected with the first material blocking plate 15 and the second material blocking plate 11 in turn from top to bottom , the upper left end of the crushing box 1 cavity is movably installed with a drive gear plate 14, the upper end of the crushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com