Naproxen injection and preparation method thereof

A technology for injection and naproxen, applied in the field of naproxen injection and preparation thereof, can solve the problems of unseen, difficult to control impurities, increased manufacturing cost and the like, and achieve the effects of improved solubility, low production cost and reduced transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

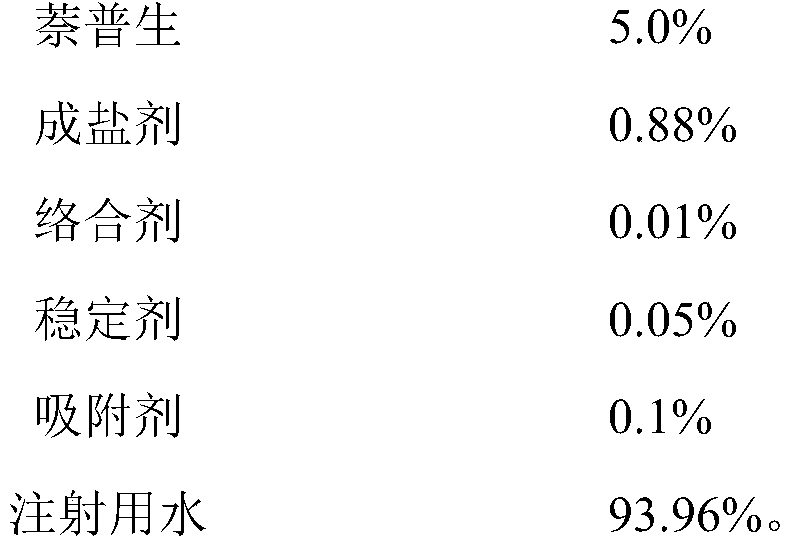

[0030] A naproxen injection prepared from the following raw materials:

[0031]

[0032]

[0033] The preparation method of above-mentioned naproxen injection, its steps are:

[0034] 1) Sodium hydroxide is mixed with water for injection to prepare a sodium hydroxide solution with a concentration of 12% by mass;

[0035] 2) First add naproxen to the remaining water for injection, then add sodium hydroxide solution, and continue to stir until the naproxen is completely dissolved, then add sodium sulfite and disodium edetate, and stir evenly. The pH value is 8.5, then add activated carbon, stir evenly and let stand for 26 minutes, then filter (remove activated carbon), fill, fill with nitrogen, seal, and finally sterilize at 117°C for 32 minutes to obtain the described naproxen Raw injections.

[0036] Test 1, the stability test of the naproxen injection of the present invention.

[0037] According to the requirements of "Technical Specifications for Drug Stability Test...

Embodiment 2

[0048] A kind of naproxen injection, is prepared from the raw material of following mass percentage:

[0049]

[0050] The preparation method of this naproxen injection, its steps are:

[0051] 1) sodium hydroxide is made into a sodium hydroxide solution with a mass percent concentration of 8% with water for injection;

[0052] 2) First add naproxen to the remaining water for injection, then add sodium hydroxide solution, and continue to stir until the naproxen is completely dissolved, then add disodium edetate and sodium citrate, and stir evenly. When the pH value of the system is 9.0, add activated carbon, stir evenly and let it stand for 20 minutes, remove the activated carbon, filter, fill, fill with nitrogen, seal, and finally sterilize at 115°C for 35 minutes to obtain the described Naproxen injection.

Embodiment 3

[0054] A kind of naproxen injection, is prepared from the raw material of following mass percentage:

[0055]

[0056]

[0057] The preparation method of this naproxen injection, its steps are:

[0058] 1) Sodium hydroxide is prepared into a 15% sodium hydroxide solution with water for injection.

[0059] 2) First add naproxen to the remaining water for injection, then add sodium hydroxide solution, and continue to stir until the naproxen is completely dissolved, then add disodium edetate and sodium citrate, and stir evenly. When the pH value of the system is 8.5, then add activated carbon, stir evenly and let it stand for 23 minutes, remove the activated carbon, then filter, fill, fill with nitrogen, seal, and finally sterilize at 121°C for 25 minutes to obtain the described Naproxen injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com